Agrement ETA 23-0707 pentru ancora surub R-HLX RAWLPLUG R-HLX-HF-ZF, R-HLX-CS-ZF

Tip documentatie: Certificare produs

Salvează pdf

Full screen

re

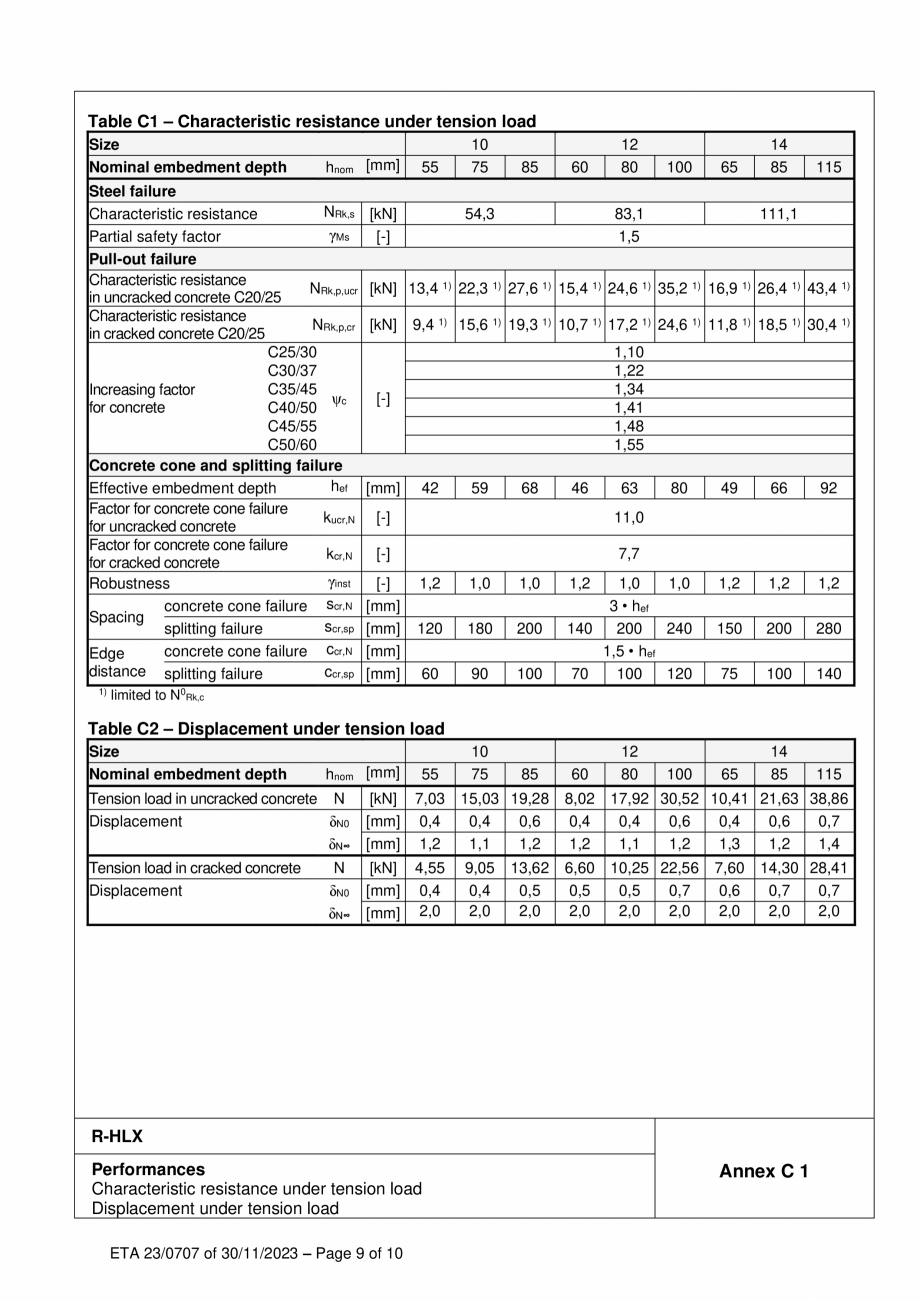

NRk,s

Characteristic resistance

γMs

Partial safety factor

Pull-out failure

Characteristic resistance

NRk,p,ucr

in uncracked concrete C20/25

Characteristic resistance

NRk,p,cr

in cracked concrete C20/25

C25/30

C30/37

C35/45

Increasing factor

ψc

for concrete

C40/50

C45/55

C50/60

Concrete cone and splitting failure

hef

Effective embedment depth

Factor for concrete cone failure

kucr,N

for uncracked concrete

Factor for concrete cone failure

kcr,N

for cracked concrete

γinst

Robustness

concrete cone failure scr,N

Spacing

scr,sp

splitting failure

concrete cone failure ccr,N

Edge

distance splitting failure

ccr,sp

1)

limited to

N0

55

[kN]

[-]

10

75

85

60

54,3

12

80

100

65

83,1

1,5

14

85

115

111,1

[kN] 13,4 1) 22,3 1) 27,6 1) 15,4 1) 24,6 1) 35,2 1) 16,9 1) 26,4 1) 43,4 1)

[kN]

9,4 1) 15,6 1) 19,3 1) 10,7 1) 17,2 1) 24,6 1) 11,8 1) 18,5 1) 30,4 1)

[-]

1,10

1,22

1,34

1,41

1,48

1,55

[mm]

42

59

68

46

63

[-]

11,0

[-]

7,7

[-]

[mm]

[mm]

[mm]

[mm]

80

49

66

92

1,2

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

3 p | RO

R-TFIX-8M

Certificare produs

13 p | RO

R-TFIX-8M