Catalog grinzi de cofrare Lana WELDE H20

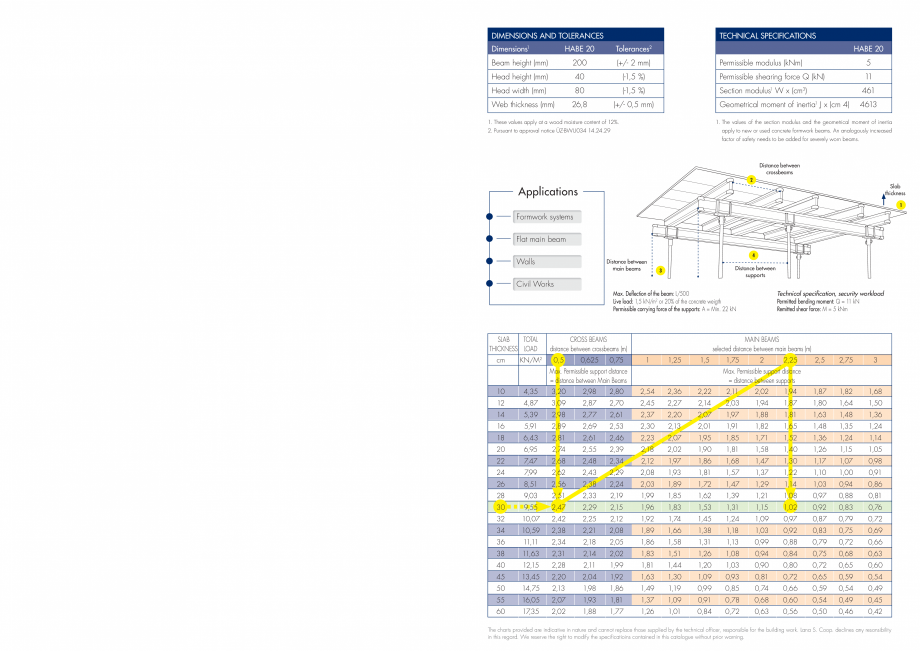

chnical specification, security workload

Permitted bending moment: Q = 11 kN

Remitted shear force: M = 5 kNm

MAIN BEAMS

selected distance between main beams (m)

1

1,25

1,5

Max. Permissible support distance

= distance between Main Beams

1,75

2

2,25

2,5

2,75

3

Max. Permissible support distance

= distance between supports

10

4,35

3,20

2,98

2,80

2,54

2,36

2,22

2,11

2,02

1,94

1,87

1,82

1,68

12

4,87

3,09

2,87

2,70

2,45

2,27

2,14

2,03

1,94

1,87

1,80

1,64

1,50

14

5,39

2,98

2,77

2,61

2,37

2,20

2,07

1,97

1,88

1,81

1,63

1,48

1,36

16

5,91

2,89

2,69

2,53

2,30

2,13

2,01

1,91

1,82

1,65

1,48

1,35

1,24

18

6,43

2,81

2,61

2,46

2,23

2,07

1,95

1,85

1,71

1,52

1,36

1,24

1,14

20

6,95

2,74

2,55

2,39

2,18

2,02

1,90

1,81

1,58

1,40

1,26

1,15

1,05

22

7,47

2,68

2,48

2,34

2,12

1,97

1,86

1,68

1,47

1,30

1,17

1,07

0,98

24

7,99

2,62

2,43

2,29

2,08

1,93

1,81

1,57

1,37

1,22

1,10

1,00

0,91

26

8,51

2

... ascunde