Catalog-Panouri fonoabsorbante - 2019 GUSTAFS Gustafs

age

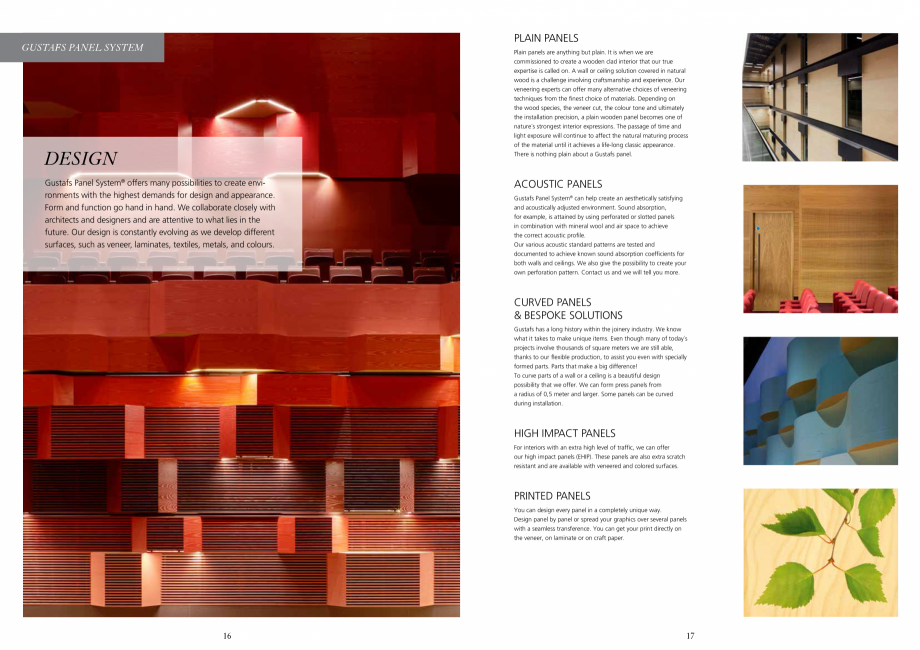

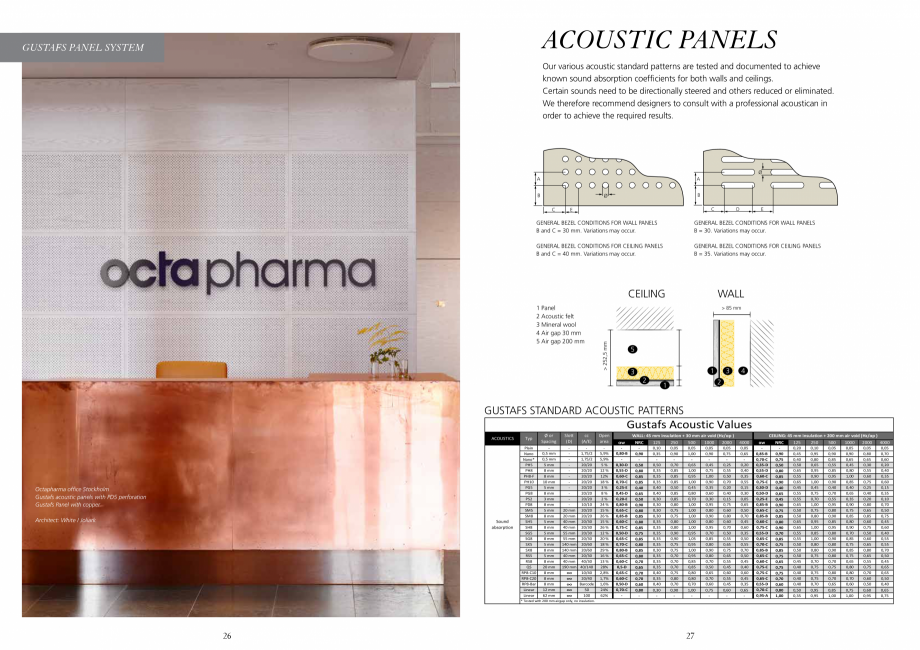

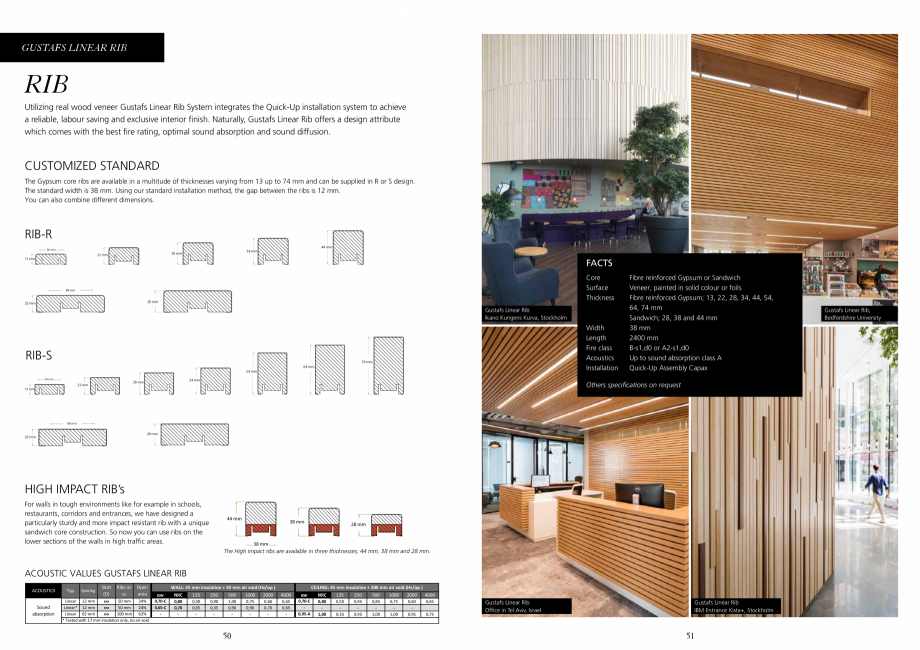

CORE

SURFACE

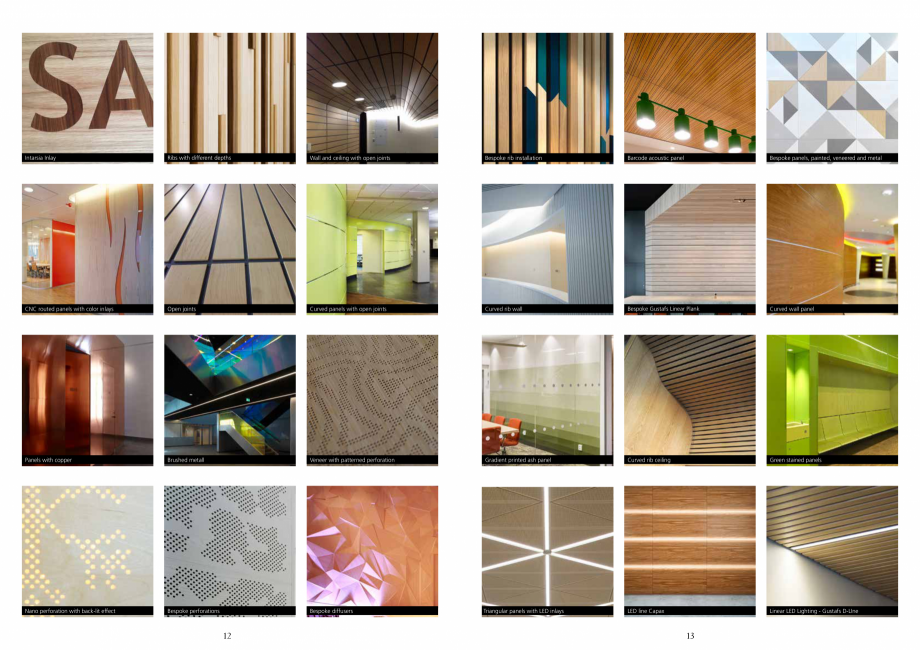

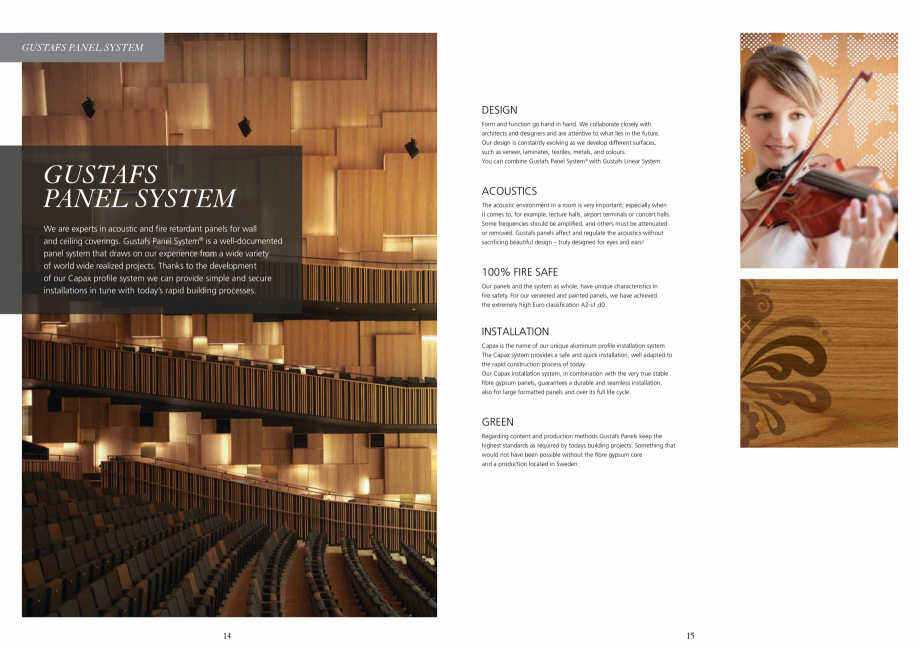

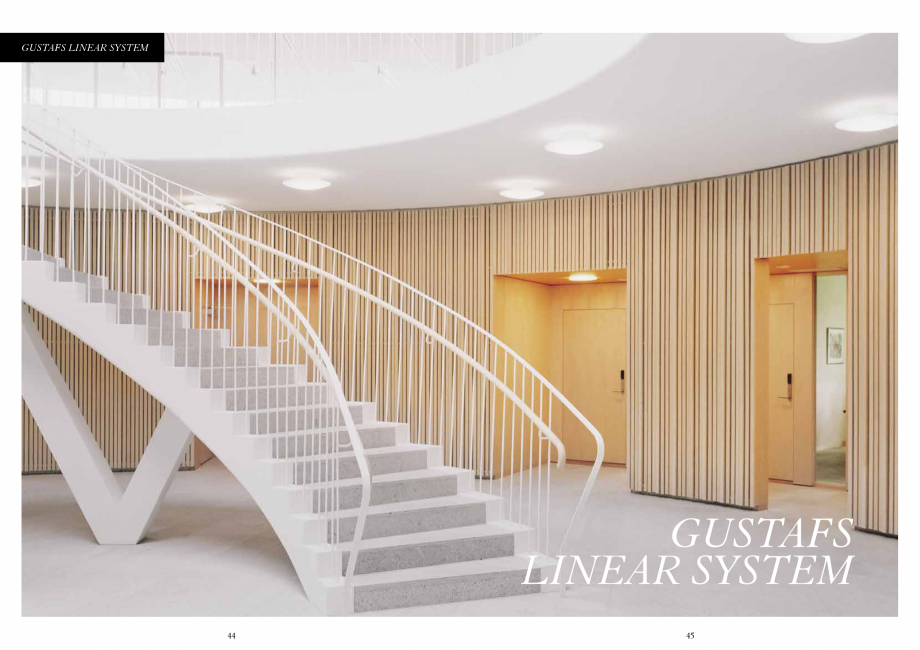

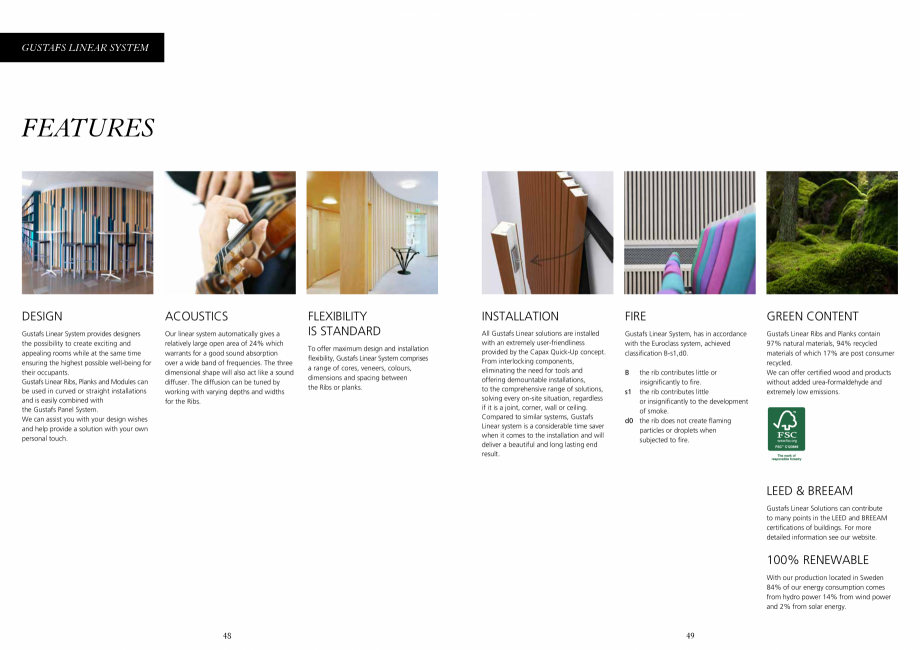

DESIGN

THICKNESS, mm

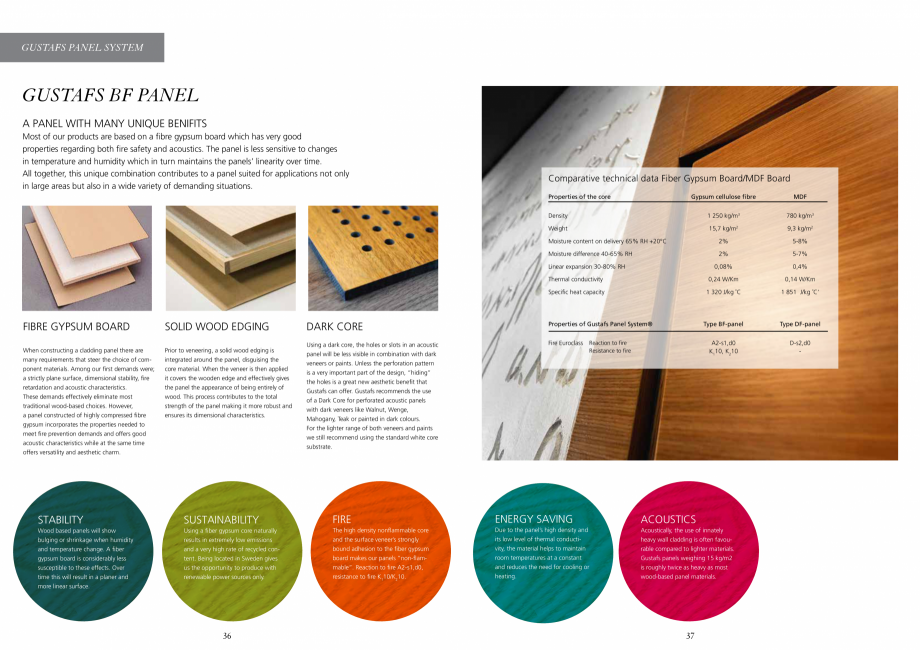

Fiber Gypsum

Coated Wood Veneer

Acoustic Perforations:

holes/slots/stripe

13,2 mm

1/1

WIDTH

LENGTH

Wall 300 - 1200

300 - 3000

Ceiling 300 - 600

ESTETICS & MAINTENANCE

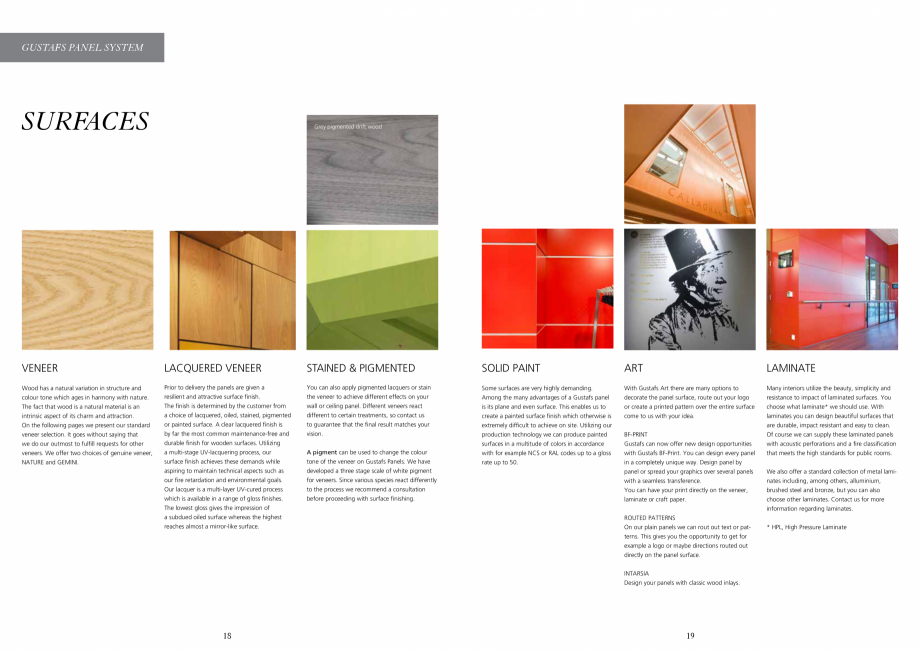

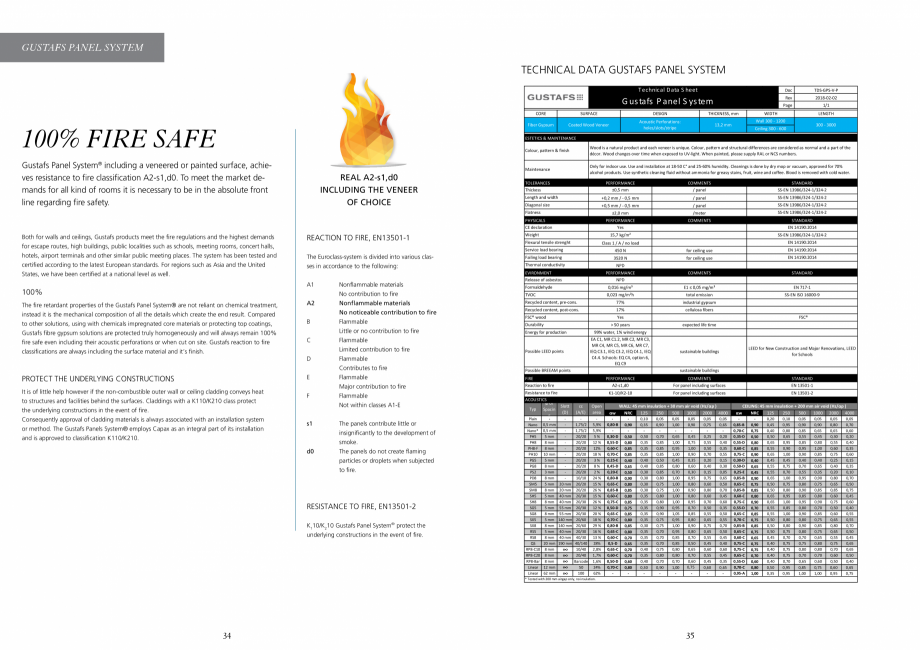

Gustafs Panel System® including a veneered or painted surface, achieves resistance to fire classification A2-s1,d0. To meet the market demands for all kind of rooms it is necessary to be in the absolute front

line regarding fire safety.

REAL

A2-s1,d0

GUSTAFS,

A FIRE-SAFE

CHOICE

EUROCLASS A2-s1, d0

INCLUDING THE VENEER

OF CHOICE

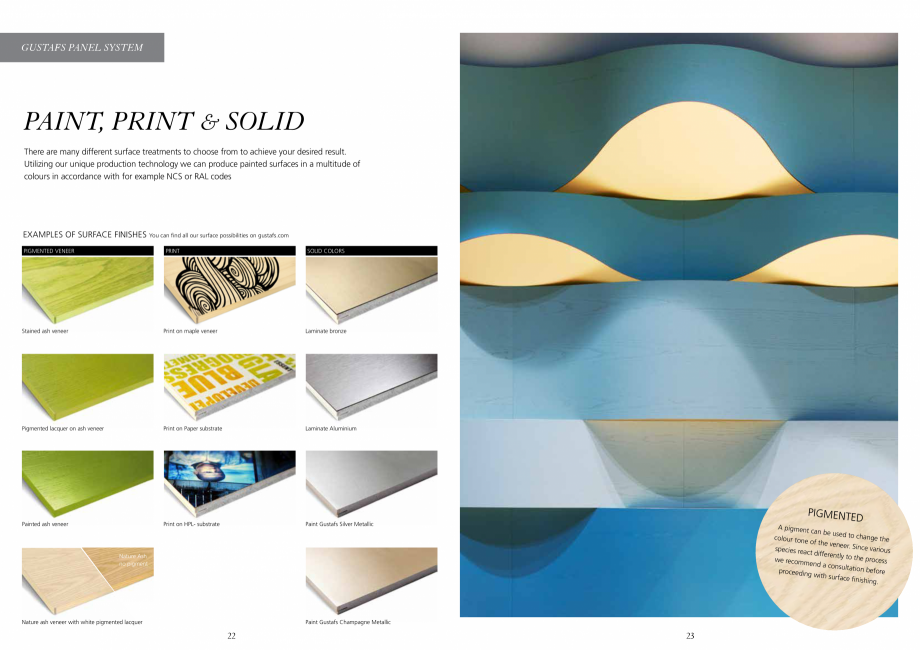

Colour, pattern & finish

Wood is a natural product and each veneer is unique. Colour, pattern and structural differences are considered as normal and a part of the

décor. Wood changes over time when exposed to UV-light. When painted, please supply RAL or NCS numbers.

Maintenance

Only for indoor use. Use and installation at 18-50 C° and 25-60% humidity. Cleanings is done by dry mop or vacuum, approved for 70%

alcohol products. Use synthe

... ascunde

Alte documentatii ale aceleasi game Vezi toate

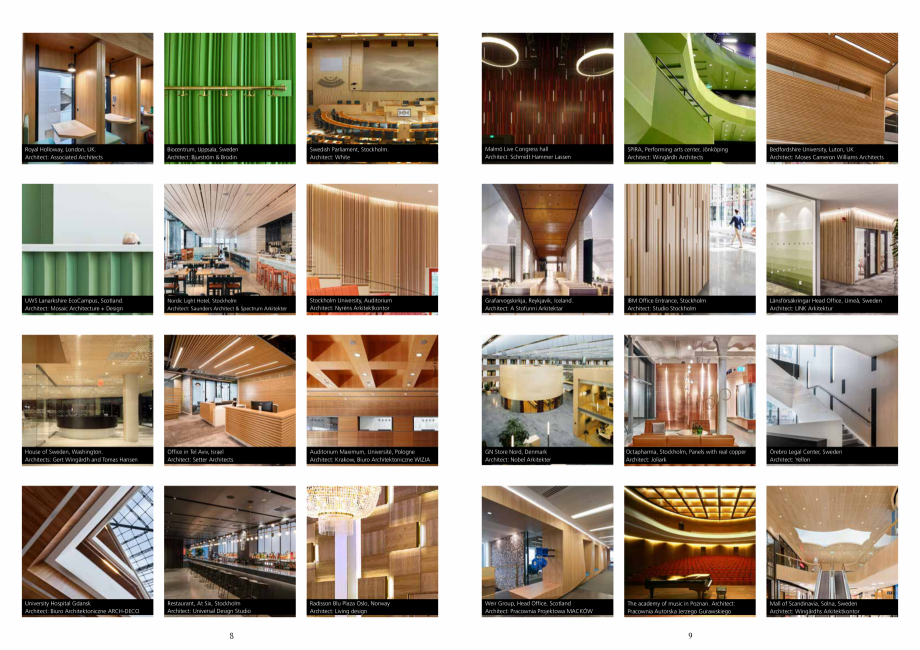

Lucrari, proiecte

Lucrari, proiecte