ffer both DX cooling and coils for chilled water. Heating can be done with either hot water,

electricity or steam heating.

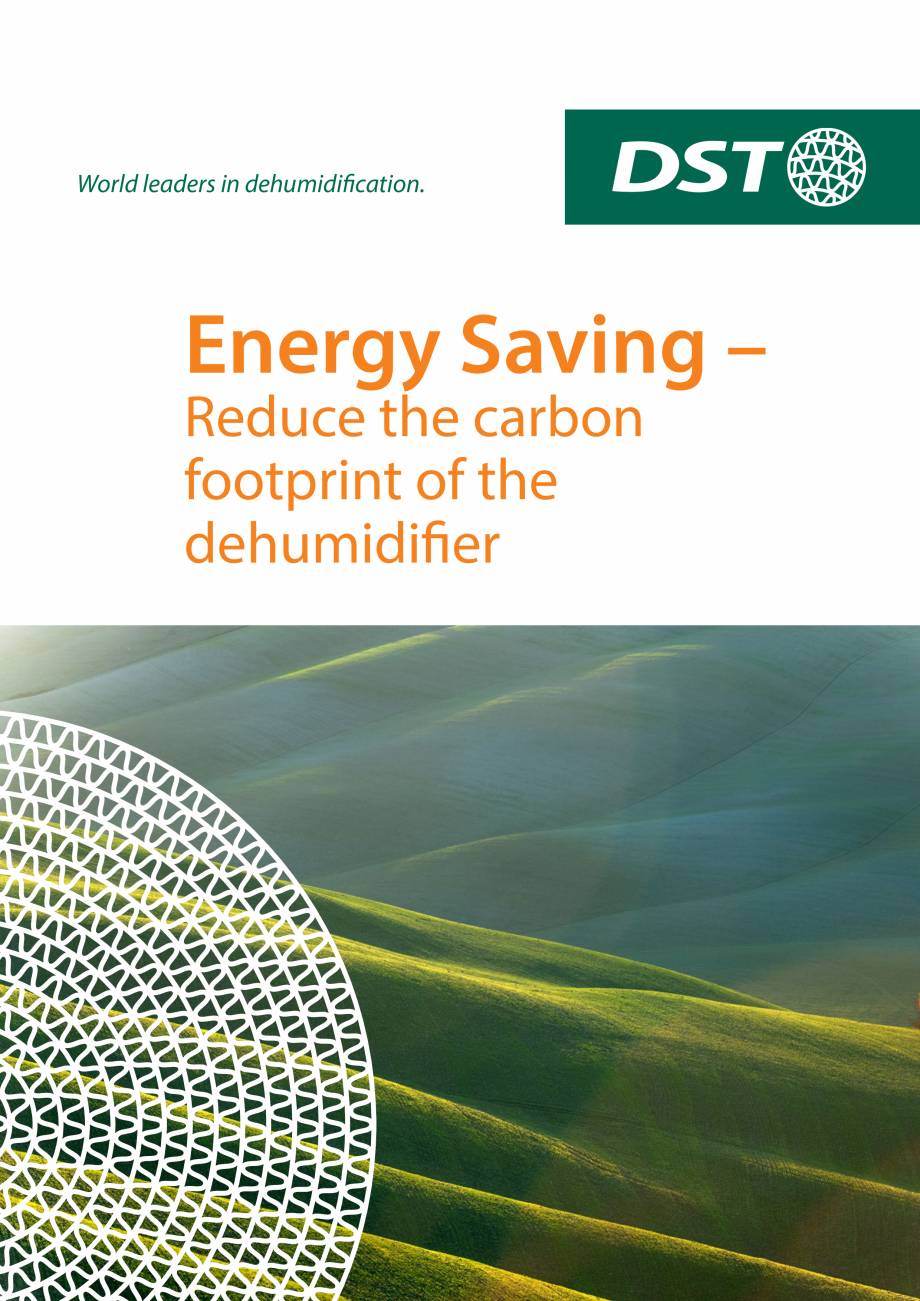

Example of configuration with options

DST provides pre- and post treatment

coils complete with temperature

control, and all from a single supplier.

Contact your nearest DST representative

for further information

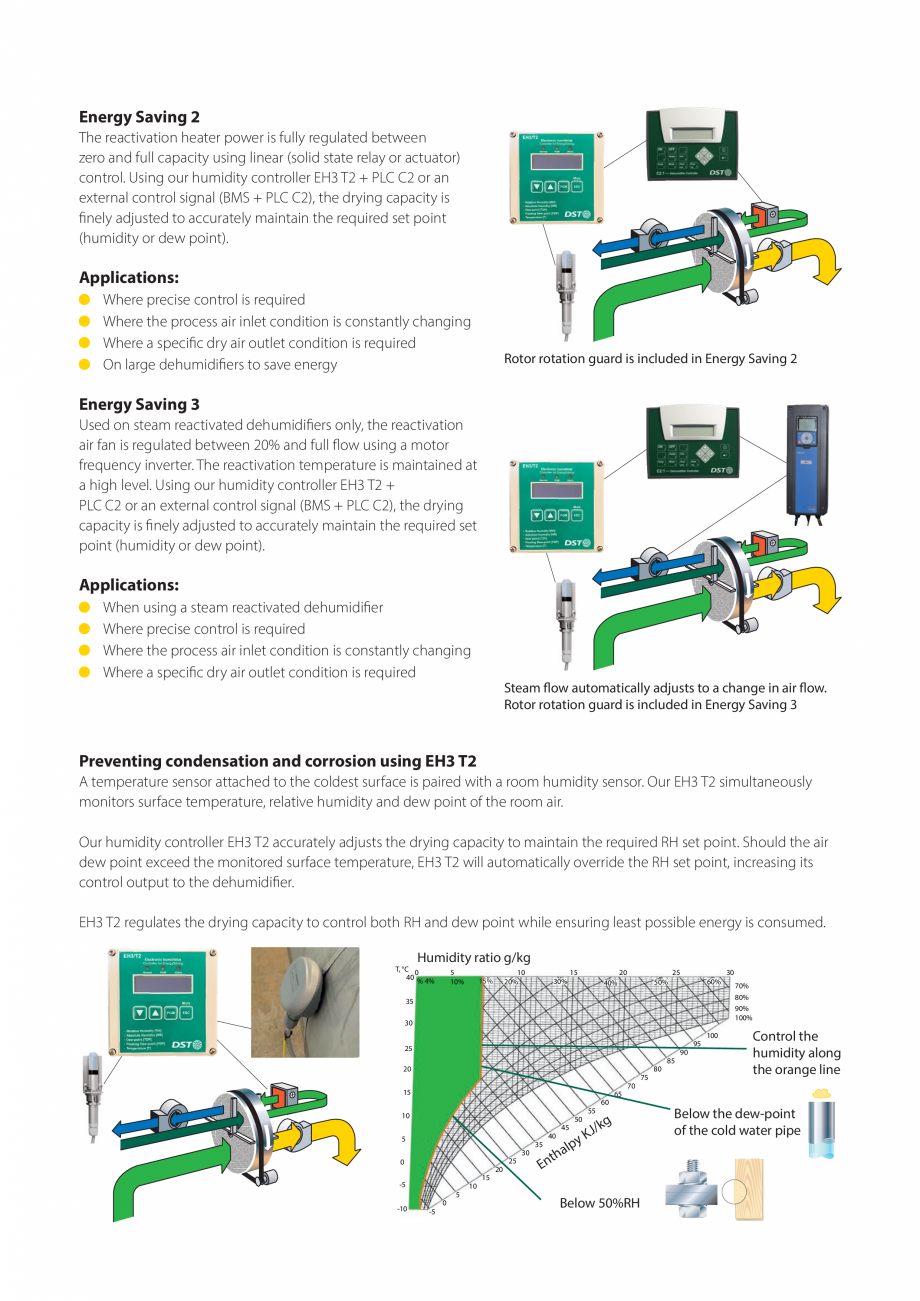

Vaisala transmitter connected to C4

Rotor

Fan

Heater

Pilot valve

Cooler

Temp. sensor

Filter

Humidity sensor

Moist warm air passes through the

dehumidifier and is supplied to the factory

as dried and cooled air

Modbus, Profibus or BACnet

Communication via TCP/IP or RTU gives the actual values

for temperature and humidity, possibility to start/stop

the dehumidifier as well as alarm readouts and operation

indicators.

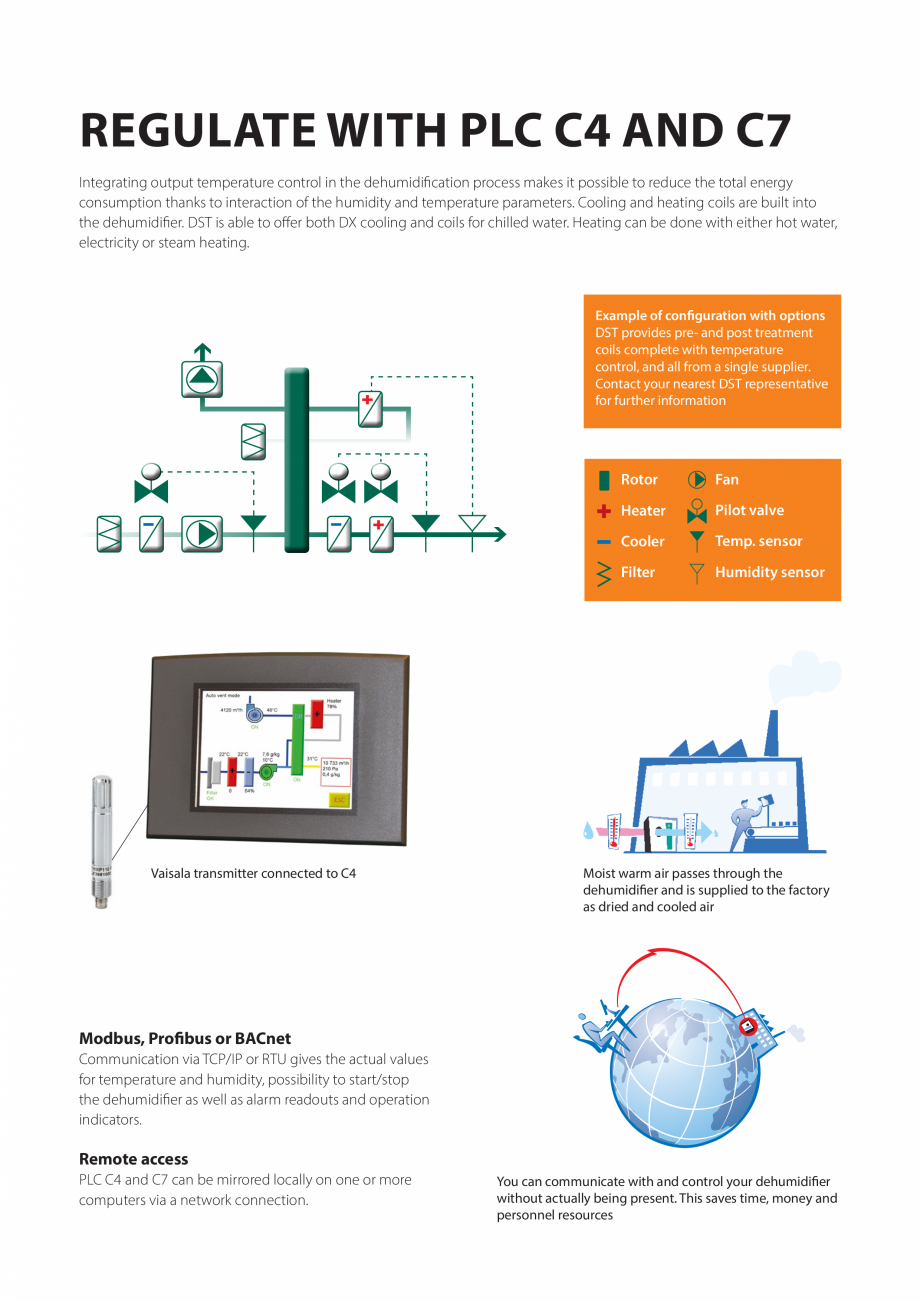

Remote access

PLC C4 and C7 can be mirrored locally on one or more

computers via a network connection.

You can communicate with and control your dehumidifier

without actually being present. This saves time, money and

personnel resour

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Catalog, brosura