Exemple utilizare - Panouri compozite din aluminiu ALUCOBOND

Limba: Engleza

Produse încluse în această documentație: ALUCOBOND® Design, ALUCOBOND® Plus, ALUCORE®, ALUCOBOND® A2

NMENTAL PROTECTION AS AN

I

NTEGRATIVE COMPONENT OF SUSTAINABILITY

MANAGEMENT AT 3A COMPOSITES

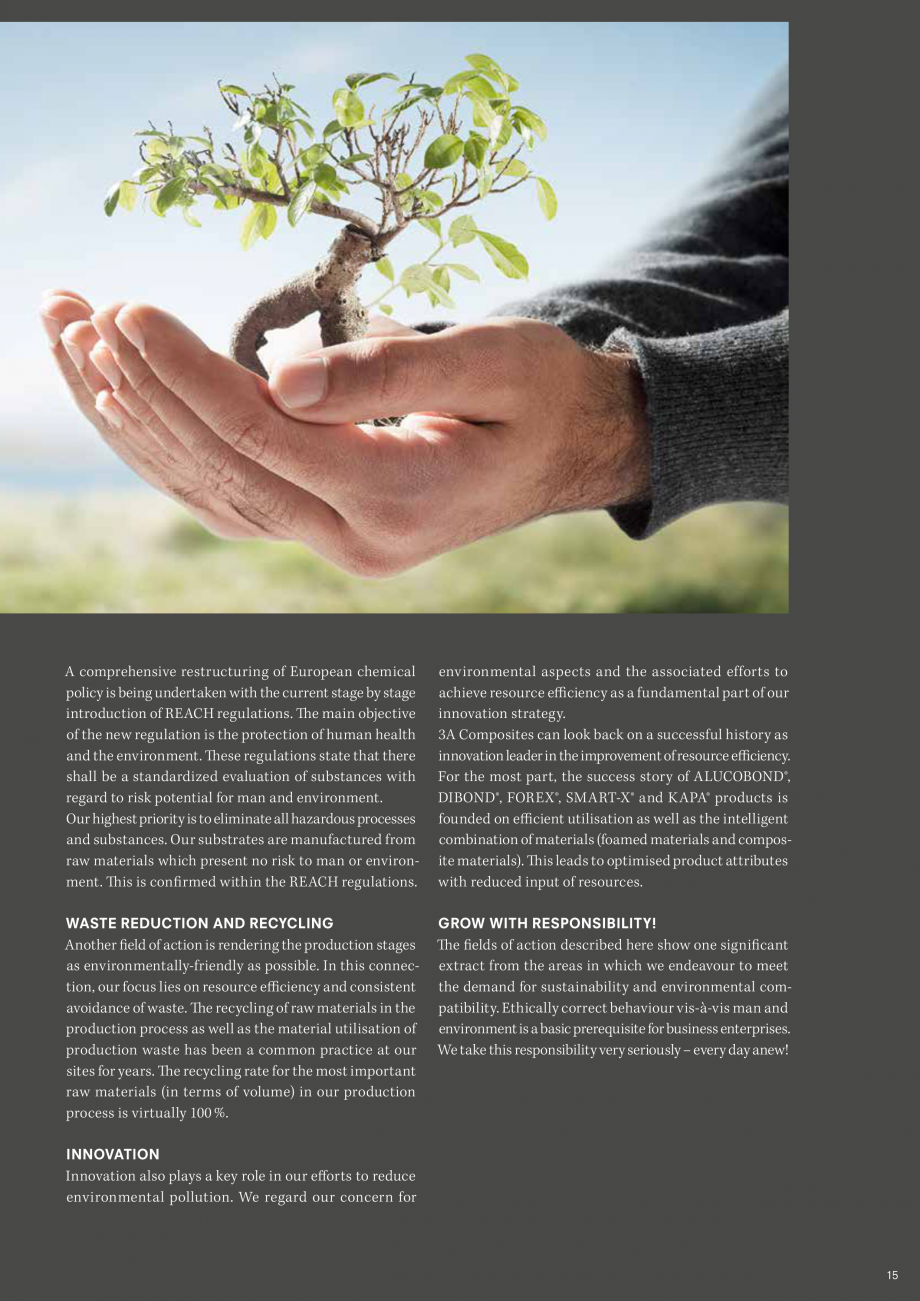

Sustainable involvement and the appurtenant sub-area

environmental protection have long been amongst our

fundamental corporate objectives at 3A Composites. The

minimization of risks for man and environment as well

as the reduction of environmental pollution through

careful and efficient utilisation of resources is part of

the corporate philosophy. 3A Composites is aware of

its responsibility as a globally active enterprise and has

been an active campaigner in matters of sustainability for

many years. Sustainability management at 3A Composites

deals with all three levels of sustainable action in depth:

the ecological, social and economic levels. In addition to

14

concrete activities, 3A Composites endeavours to create

transparent communication and seeks dialogue with all

interest groups.

ENVIRONMENTAL MANAGEMENT SYSTEMS

Our three production sites in Germany and Switzerland

have been cert

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

Fisa tehnica