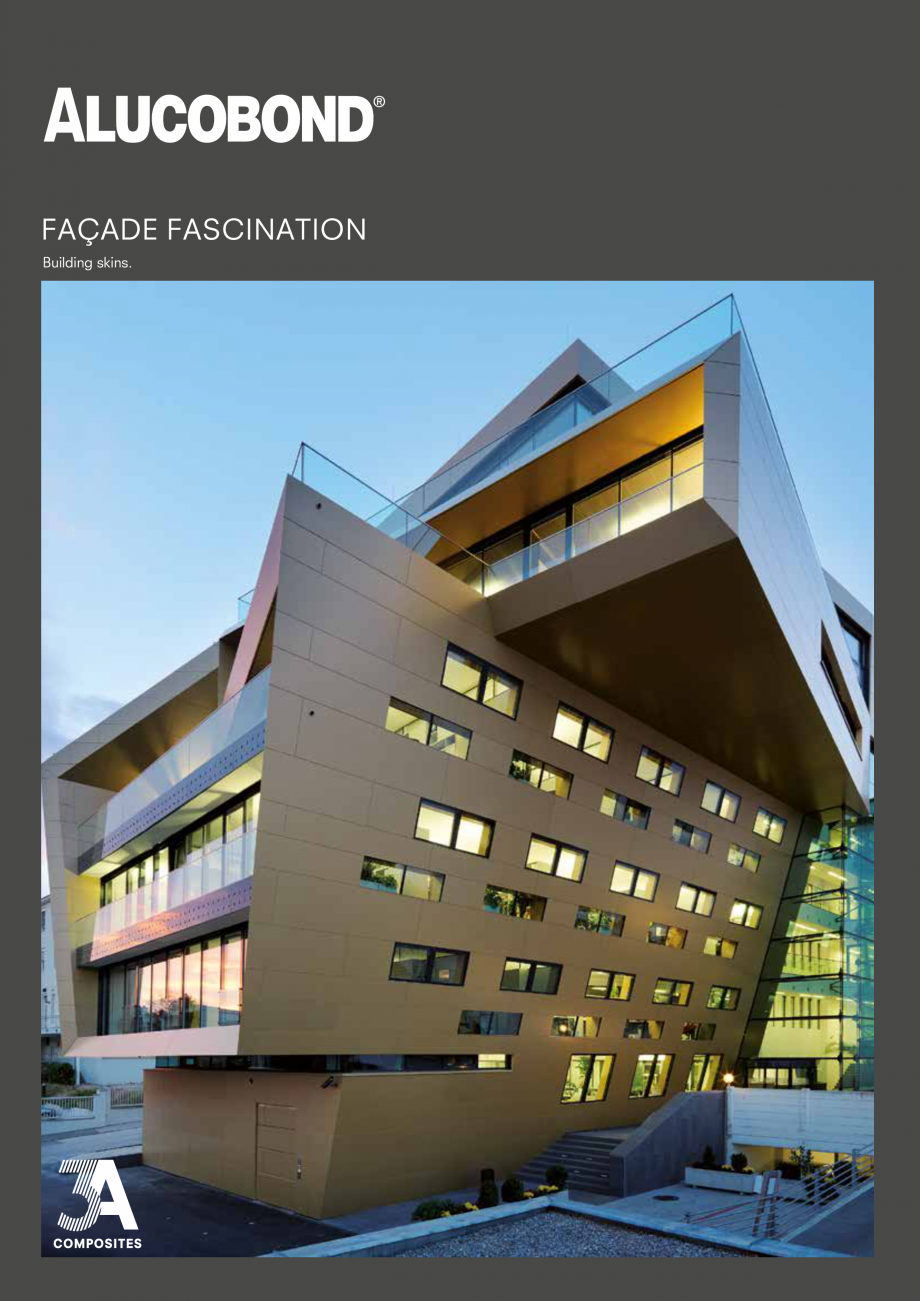

Fatade realizate cu panourile compozite din aluminiu ALUCOBOND

Limba: Engleza

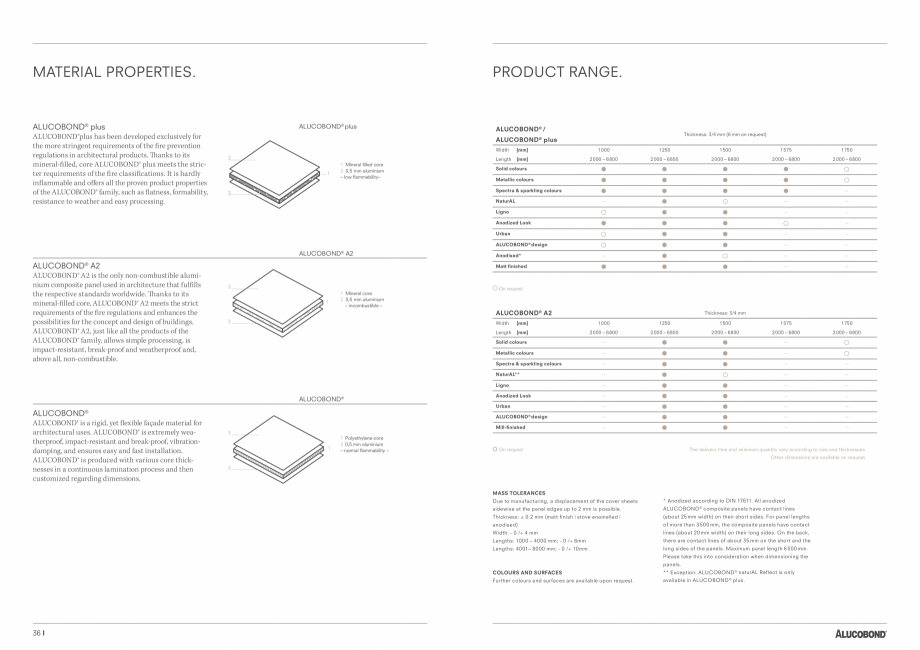

Produse încluse în această documentație: ALUCOBOND® Plus, ALUCORE®, ALUCOBOND® A2, ALUCOBOND® Design

D ® Panels and cassettes elements

ФЦС, Moskow

Singapore

011937

Product listing scheme: class 2

PSB Singapore

Slovakia

TO-06/0275

ALUCOBOND ®

TSUS, Bratislava

Spain

No 345

Sistema de revistimiento de fachadas ventiladas mediante

bandejas procedentes de paneles ALUCOBOND ®

Instituto Eduardo Toroja, Madrid

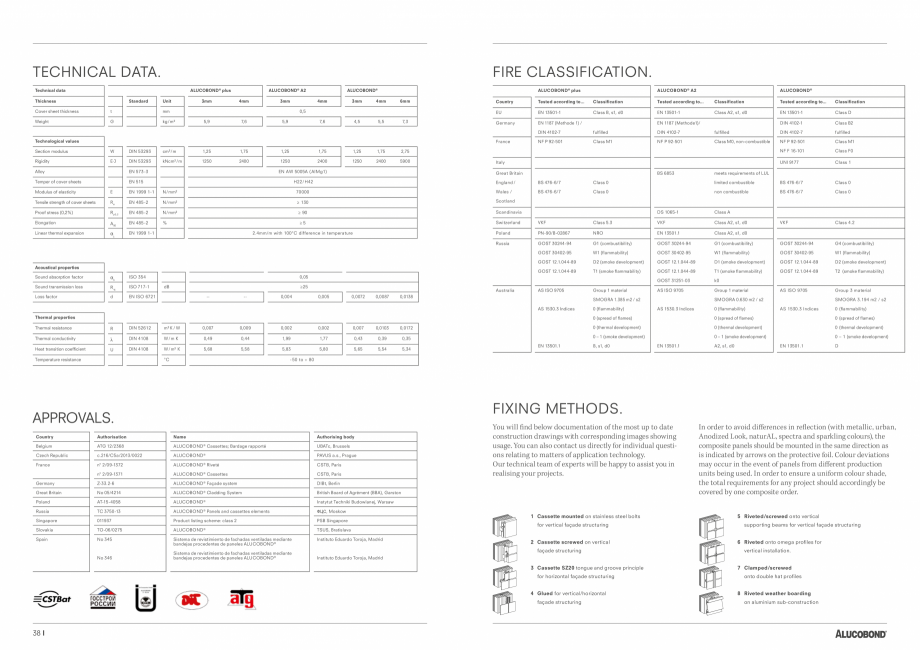

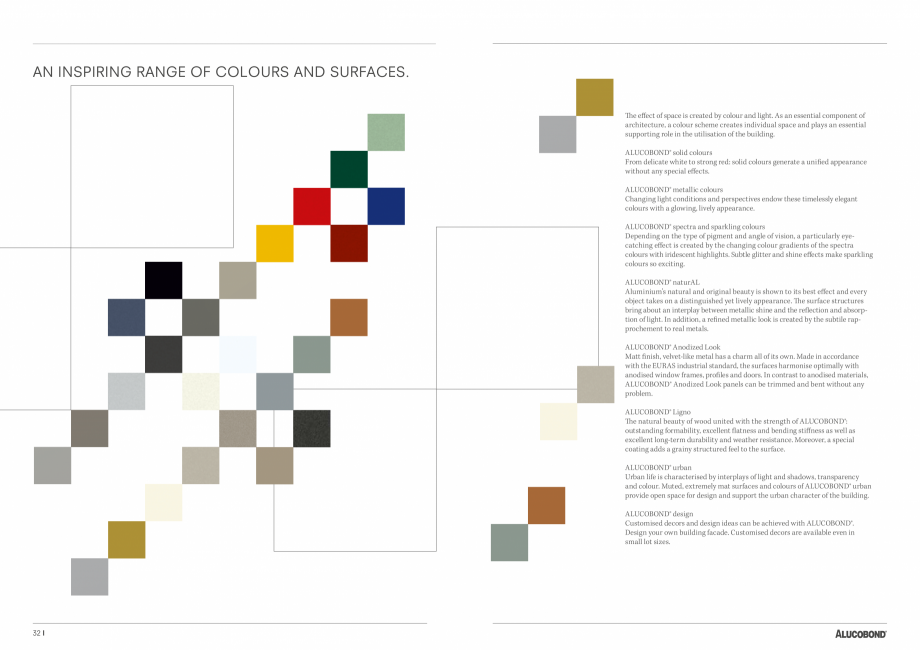

In order to avoid differences in reflection (with metallic, urban,

Anodized Look, naturAL, spectra and sparkling colours), the

composite panels should be mounted in the same direction as

is indicated by arrows on the protective foil. Colour deviations

may occur in the event of panels from different production

units being used. In order to ensure a uniform colour shade,

the total requirements for any project should accordingly be

covered by one composite order.

Instytut Techniki Budowlanej, Warsaw

Russia

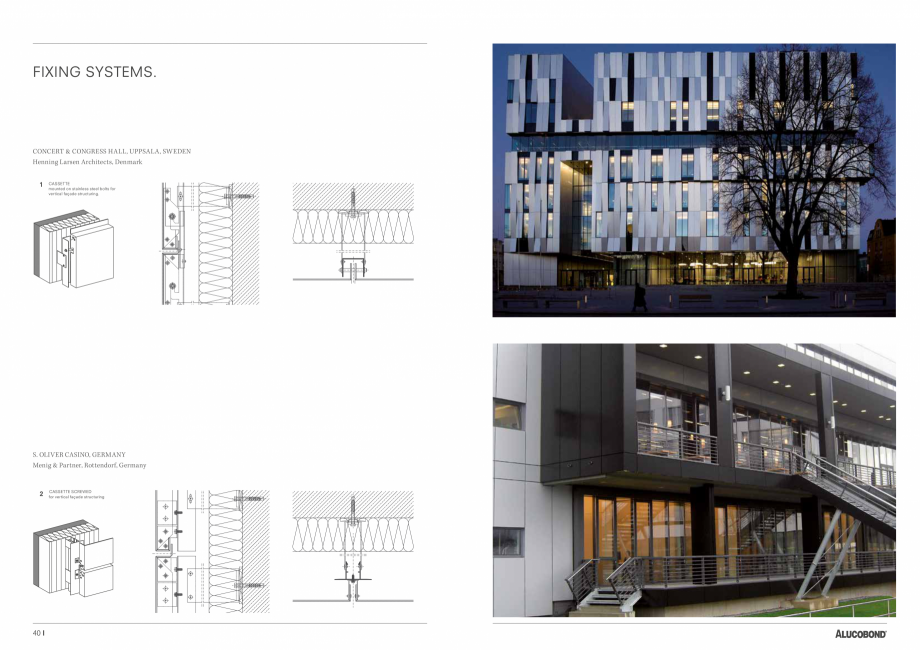

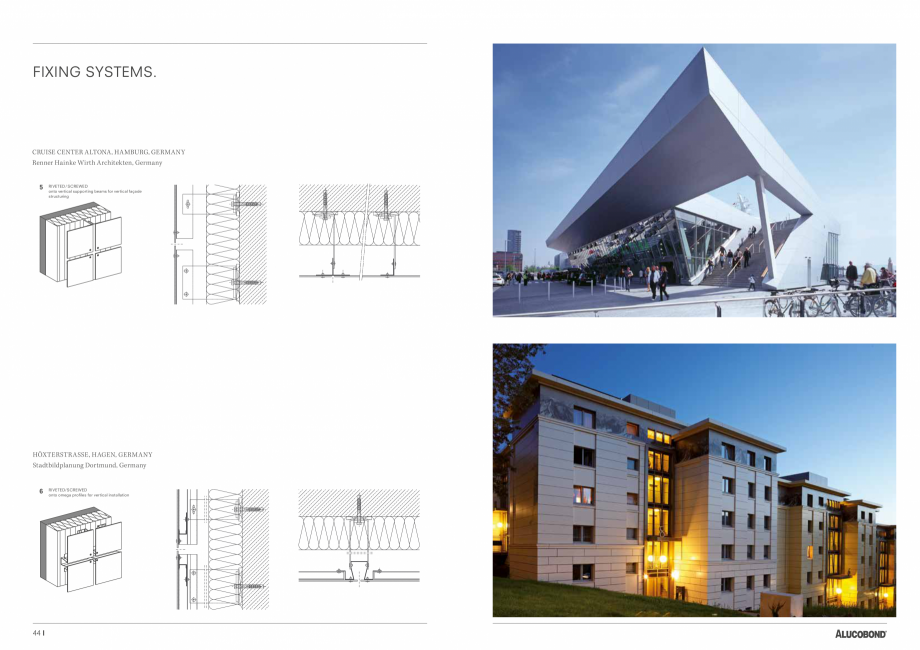

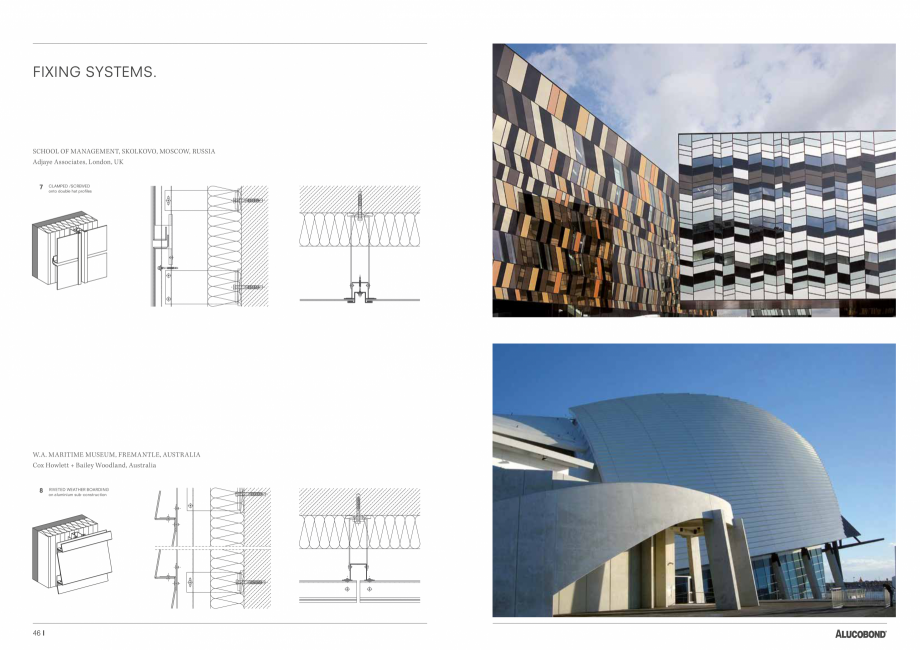

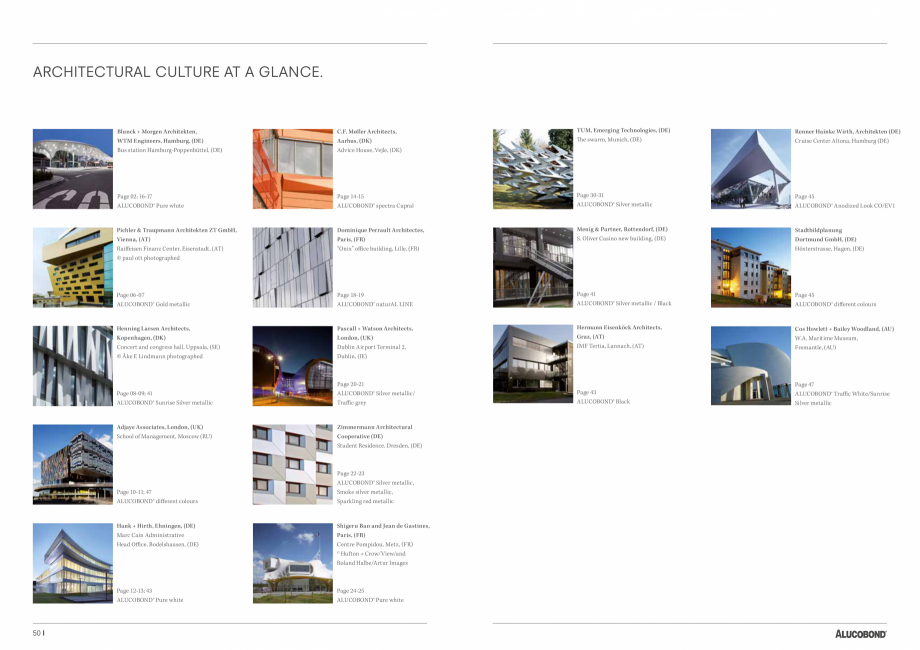

You will find below documentation of the most up to date

construction drawings with corresponding images showing

usage. You can also contact us directly for indivi

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

Fisa tehnica