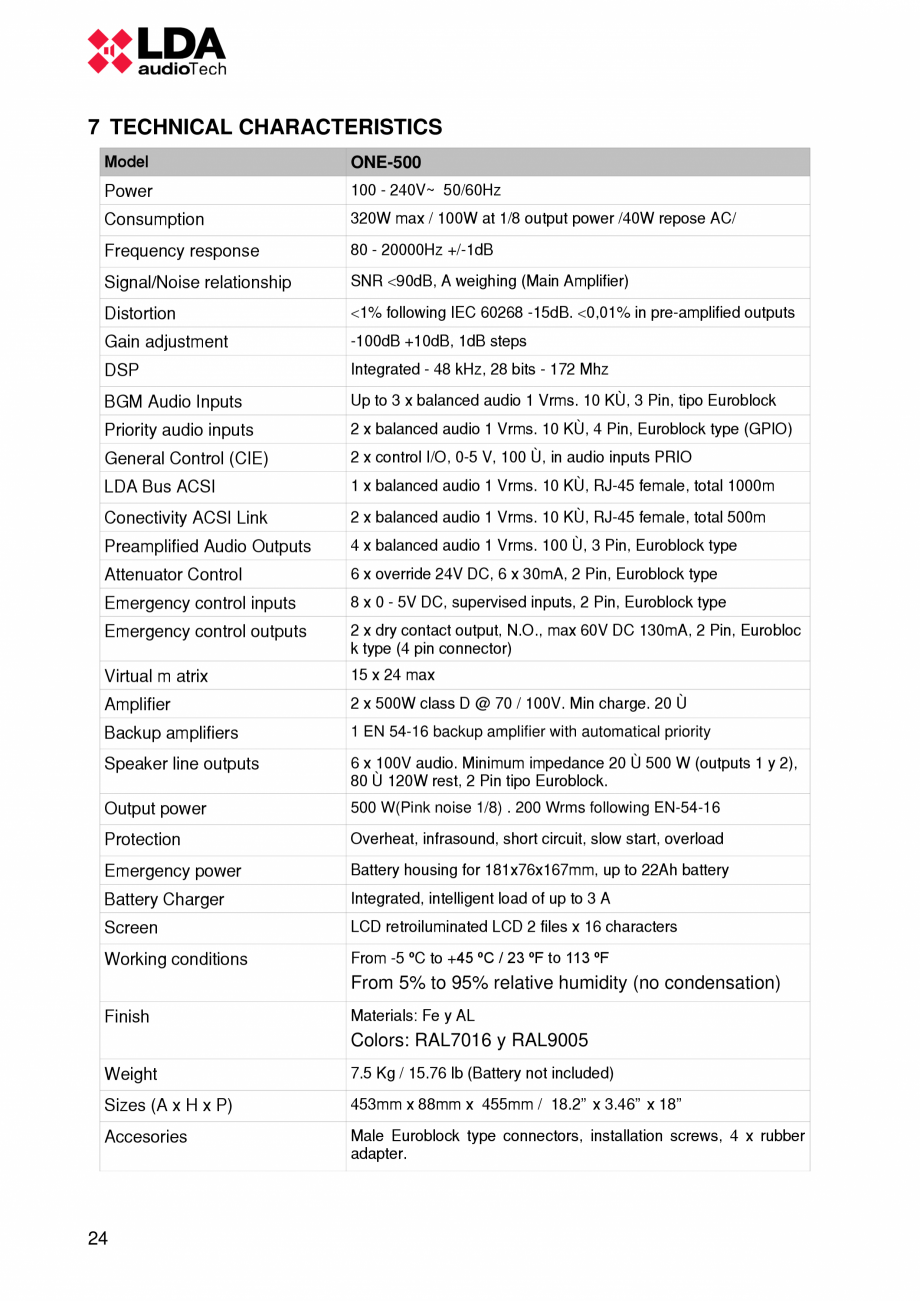

Manualul utilizatorului - Unitate centrala sistem de evacuare si adresare publica compact EN54-16 LDA Audio Tech ONE-500

Tip documentatie: Instructiuni montaj, utilizare

Salvează pdf

Full screen

the \DATAxx

folder. If there is a previous configuration, it overwrites the previous data.

• Import Sys CFG: It imports the data from folder DATAxx from the USB memory.

3.3.9 System. System configuration

System general parameters configuration:

• Info: Shows system information, FW version, serial number...

• AutoSetup: Launches the automatic system configuration by EN54. See details at

section 3.2 Automatic Configuration. Autoset.

• Software Reset. Restarts the system and internal processors.

• Factory Reset: Returns the system to its Factory configuration. It deletes all the

parameters configured by the user, except for the logs.

• FW_Update: Allows to actualize firmware version by a file in USB memory.

◦ NOTE: File must be in the root directory and be called fw.bin or update.bin

• Erase Logs: Mades a failure and emergency logs erase.

• Logs Interval: It allows to configure the time of permanence of the entries of the

logs. You can choose the days of permanence or s

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

2 p | EN

NEO 8060 PA/VA

Instructiuni montaj, utilizare

56 p | EN

NEO 4250-E