Placa izolatoare monostrat din fibre lemnoase GUTEX Thermoroom

the abbreviation used

here for insulation thickness.

Table 4

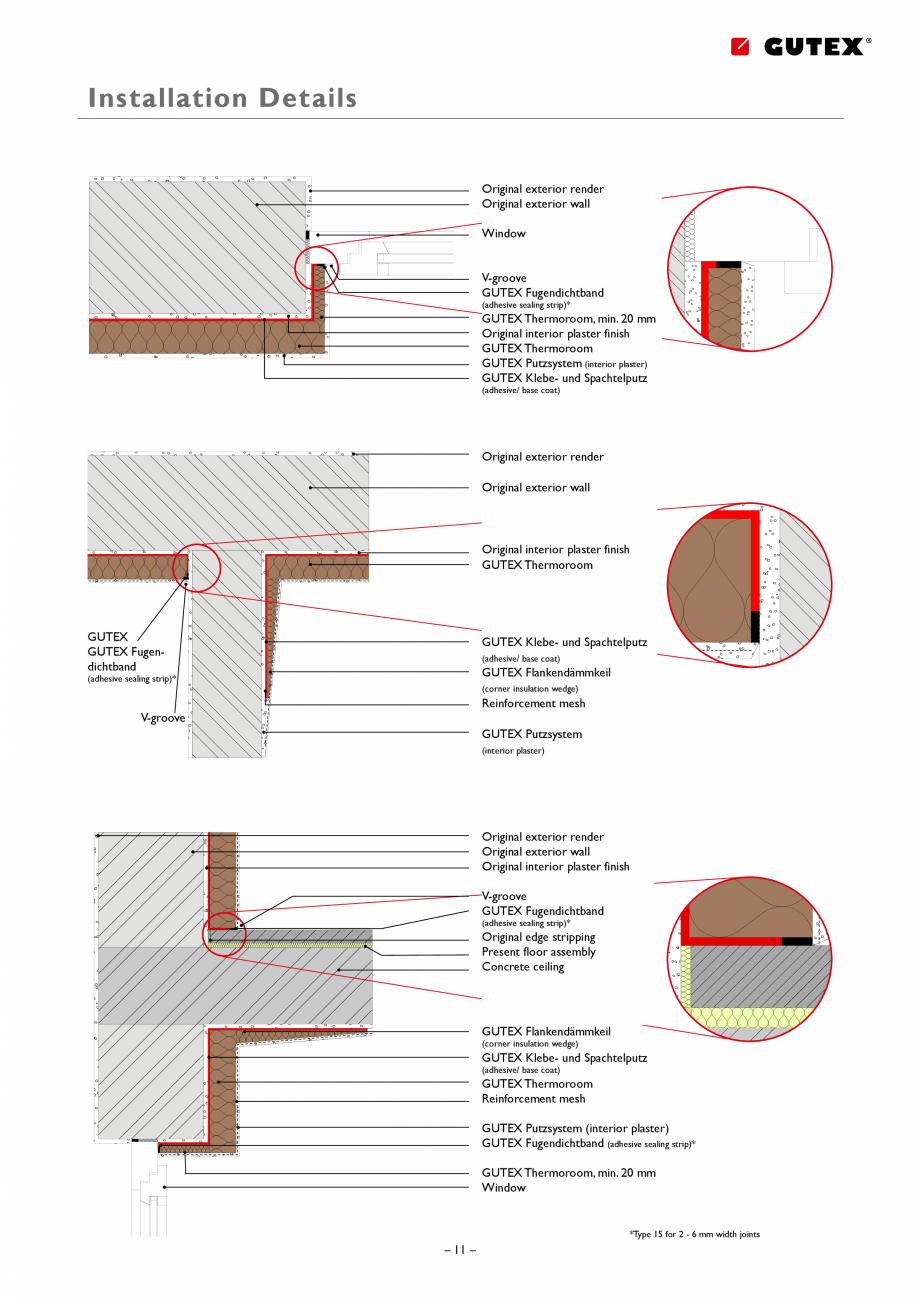

Hinweis: Dieses Detail ist ein allgemeiner Planungsvorschlag, welcher schematisch die Ausführung eines WDVS darstellt. Anwendbarkeit und Vollständigkeit sind vom Verarbeiter/Kunden beim jeweiligen

Bauvorhaben eigenverantwortlich zu prüfen. Angrenzende Gewerke sind nur schematisch. Alle Vorgaben und Annahmen sind auf die örtlichen gegebenheiten anzupassen bzw. abzustimmen. Die jeweiligen

technischen Vorgaben in den Merkblättern und Systemzulassungen sind zu beachten.

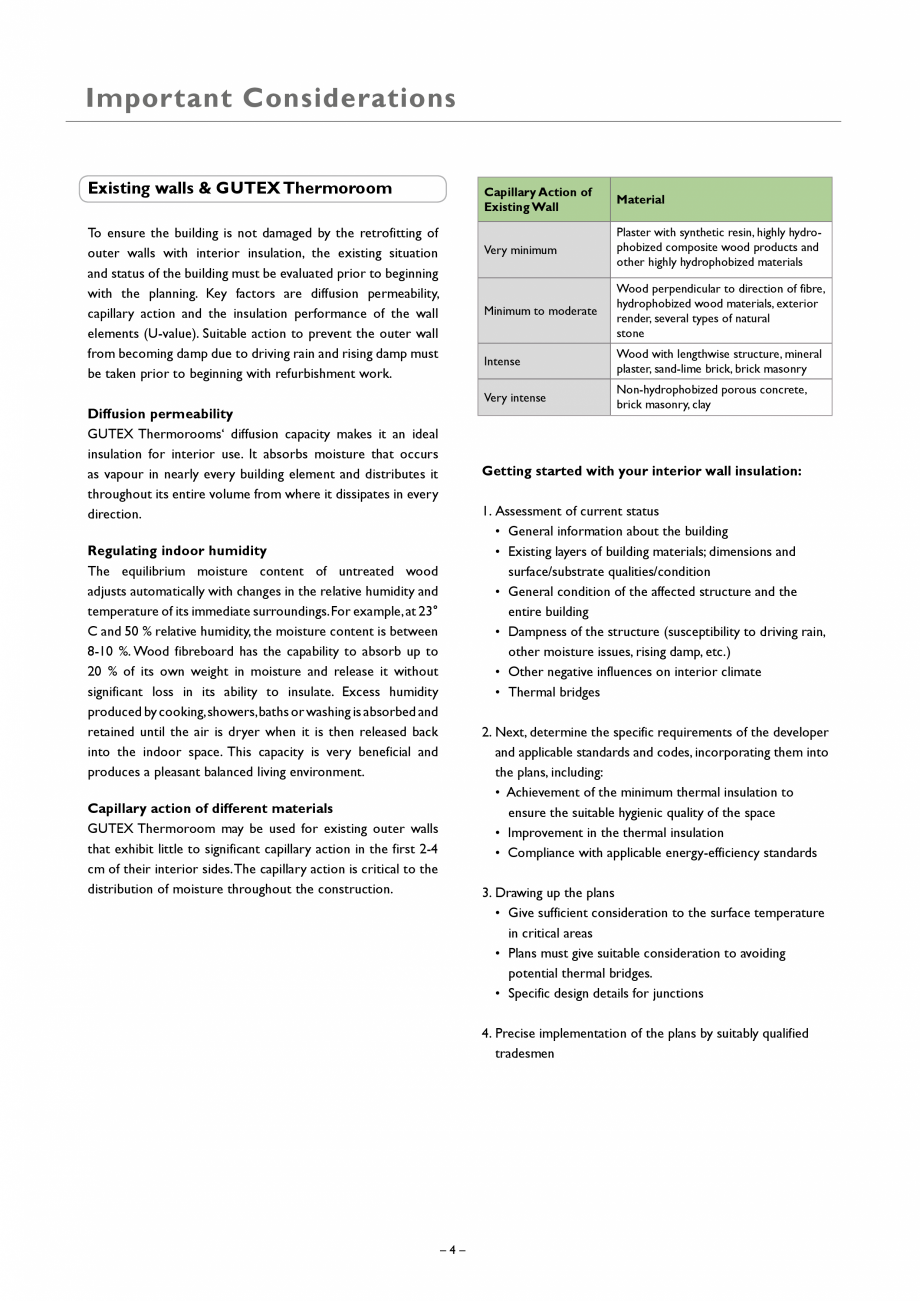

Table 2

Detail Innendämmung

Anschluss AW-IW

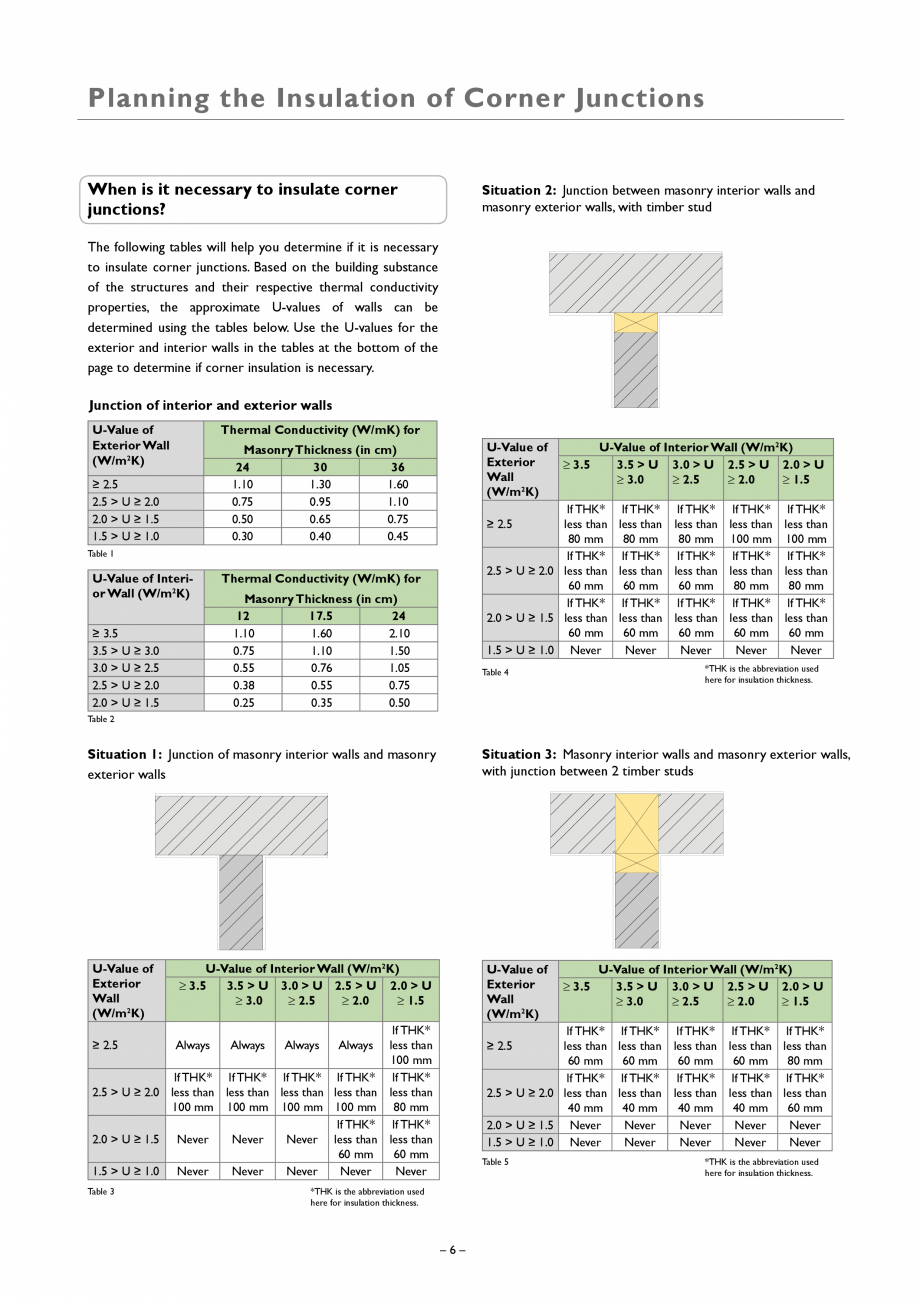

Situation 1: Junction of masonry interior walls and masonry

exterior walls

U-Value of

Exterior

Wall

(W/m2K)

Situation 3: Masonry interior walls and masonry exterior walls,

with junction between 2 timber studs

U-Value of Interior Wall (W/m2K)

≥ 3.5

3.5 > U 3.0 > U 2.5 > U 2.0 > U

≥ 3.0

≥ 2.5

≥ 2.0

≥ 1.5

U-Value of

Exterior

Wall

(W/m2K)

Hinweis: Dieses Detail ist ein allgemeiner Planungsvorschlag,

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

2 p | RO

Multitherm

Fisa tehnica

3 p | RO

Thermoflex