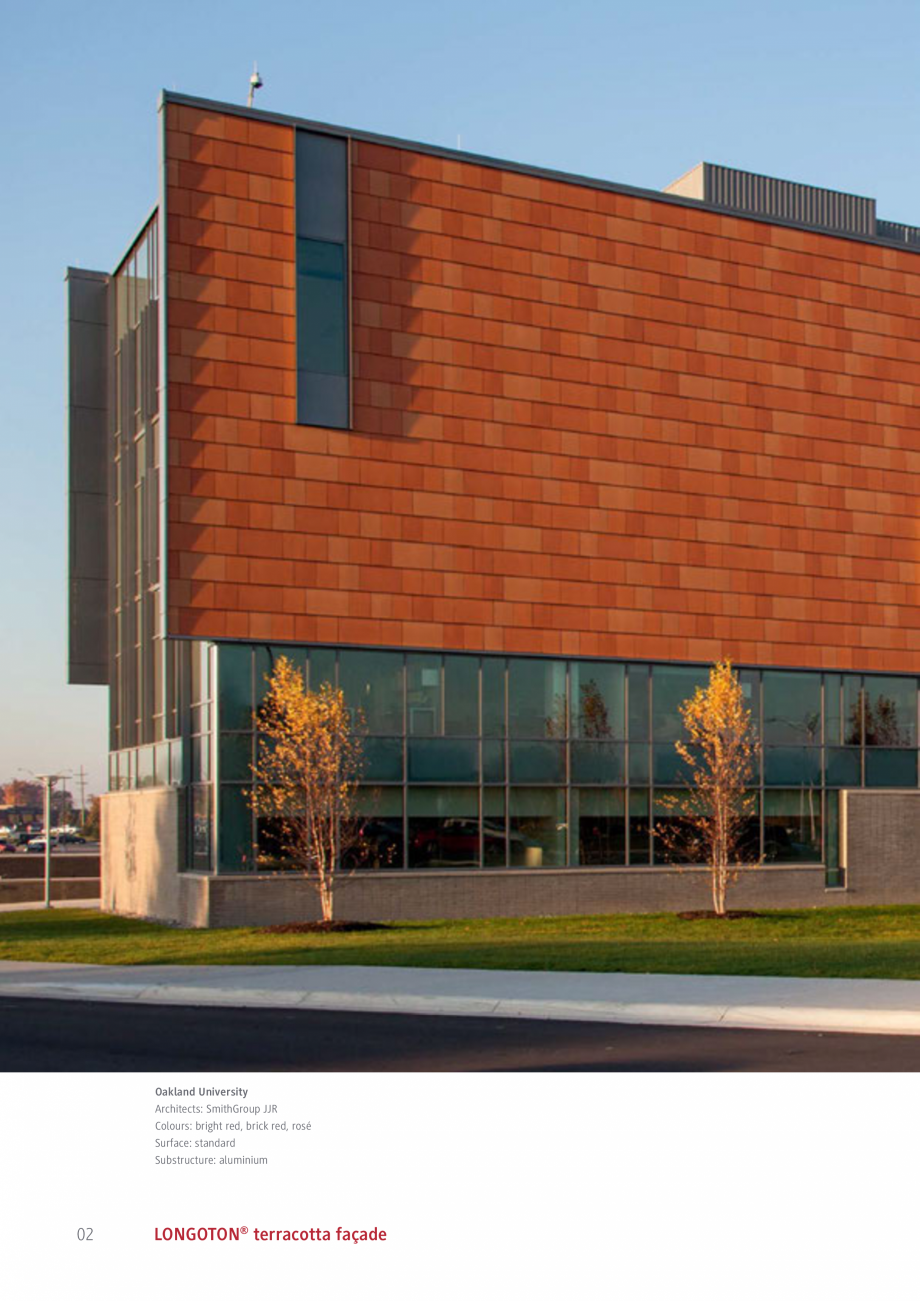

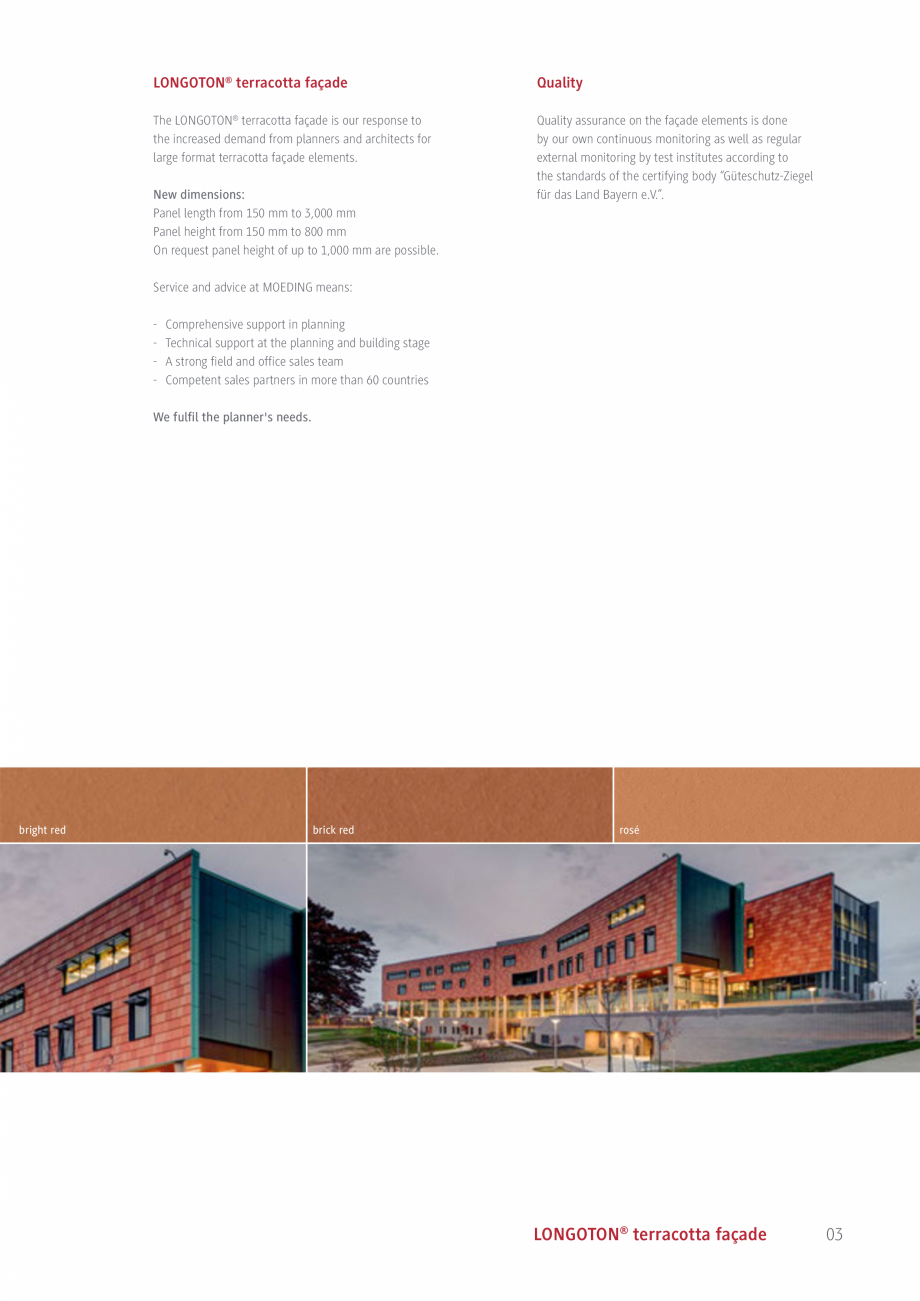

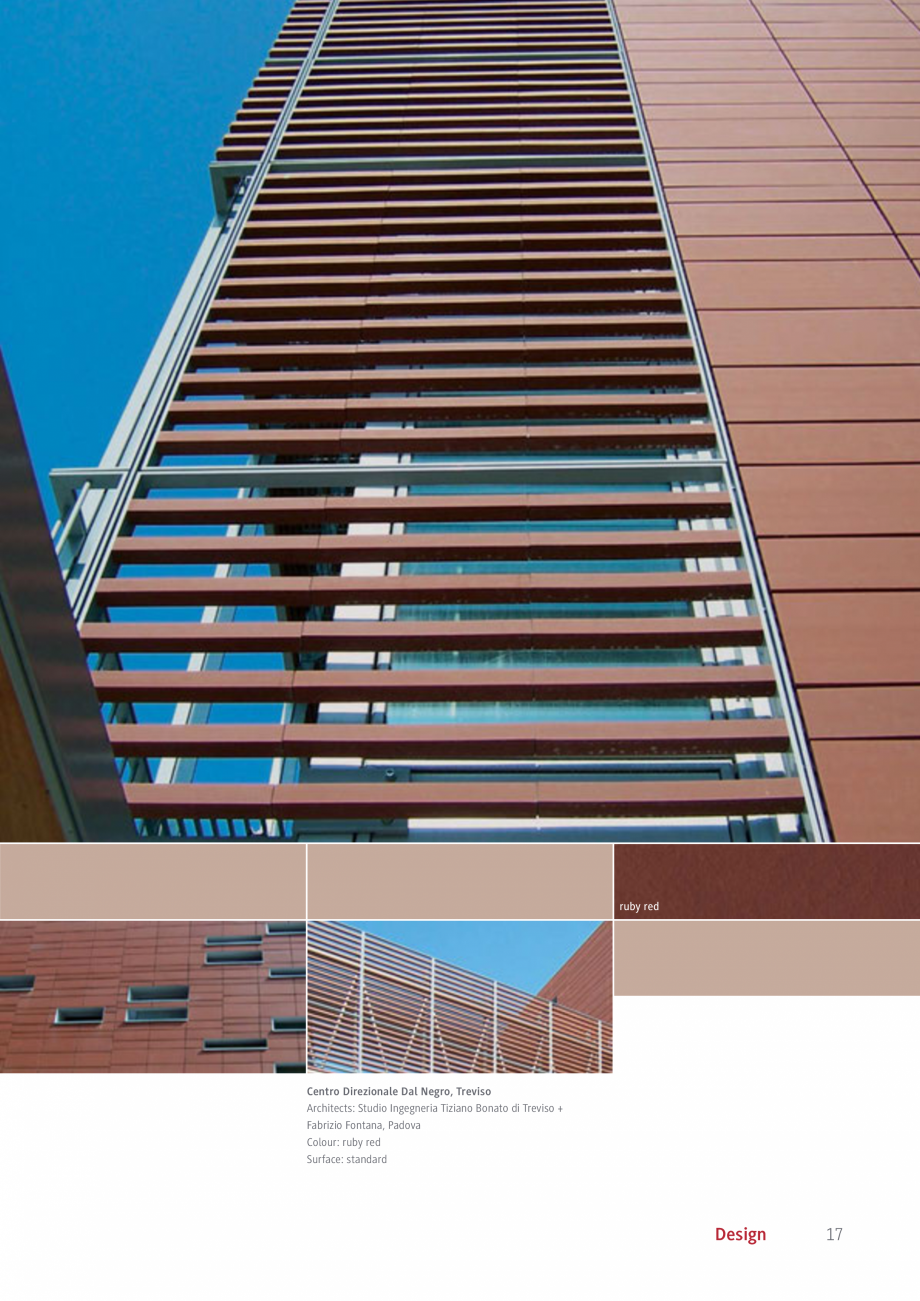

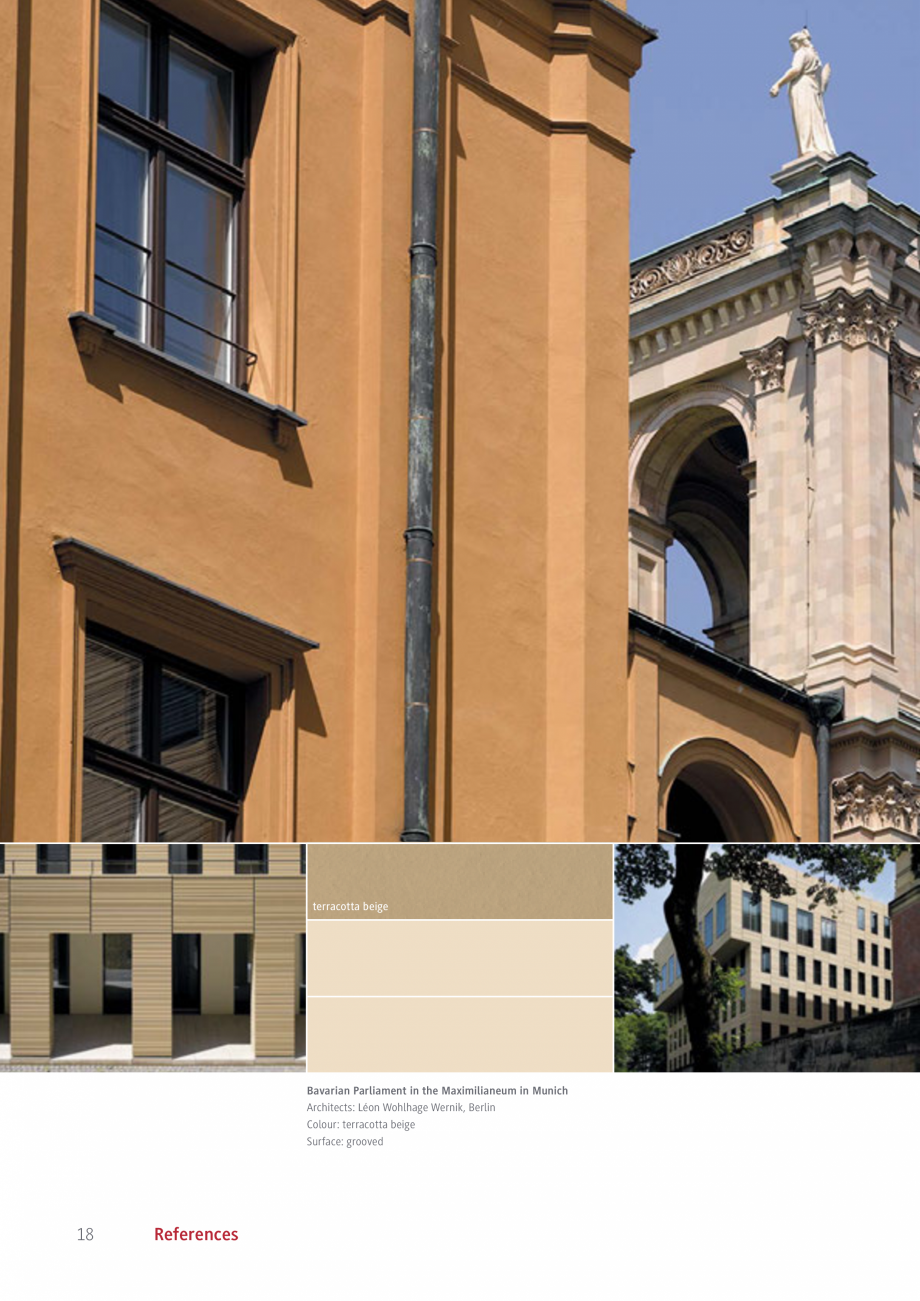

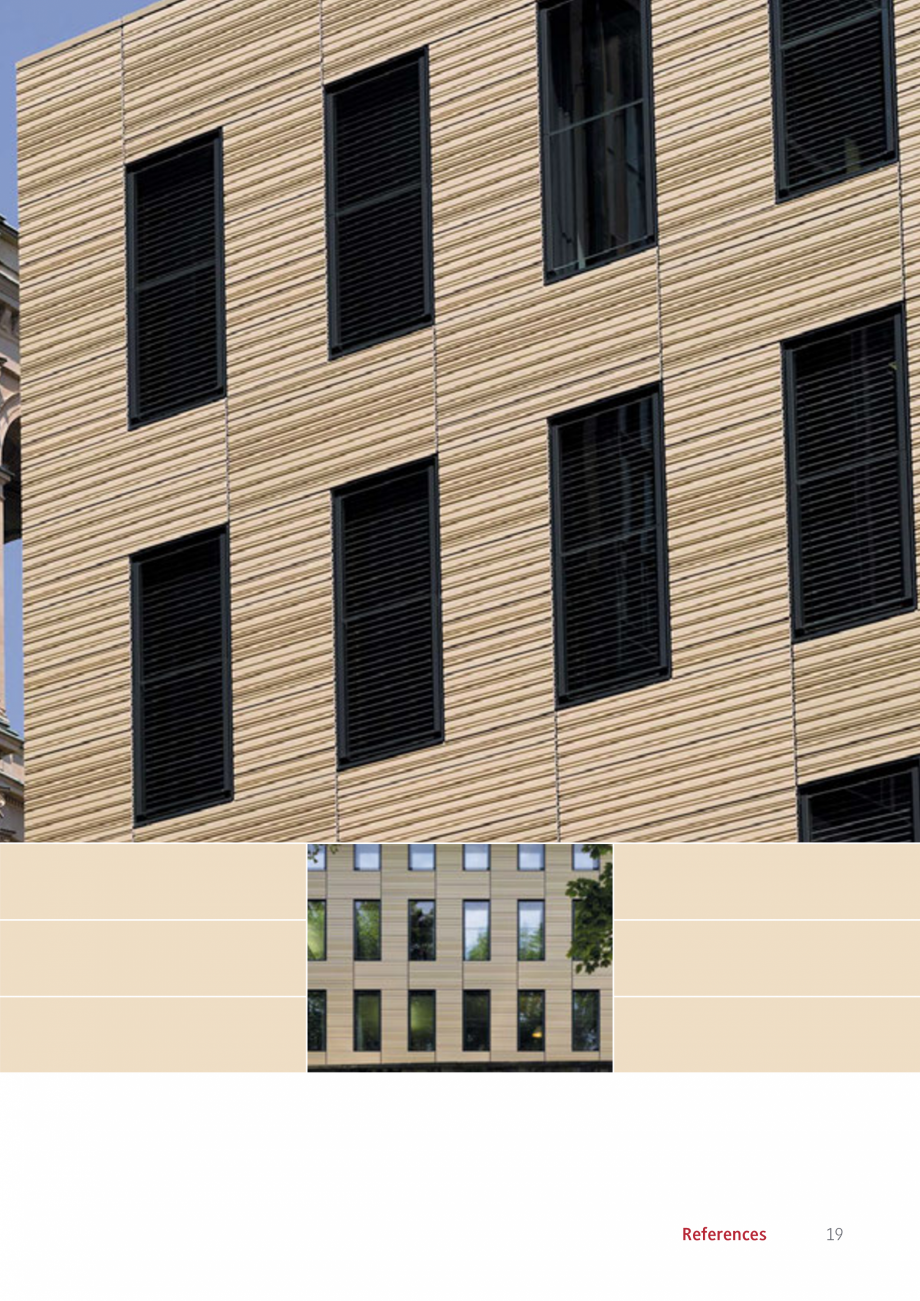

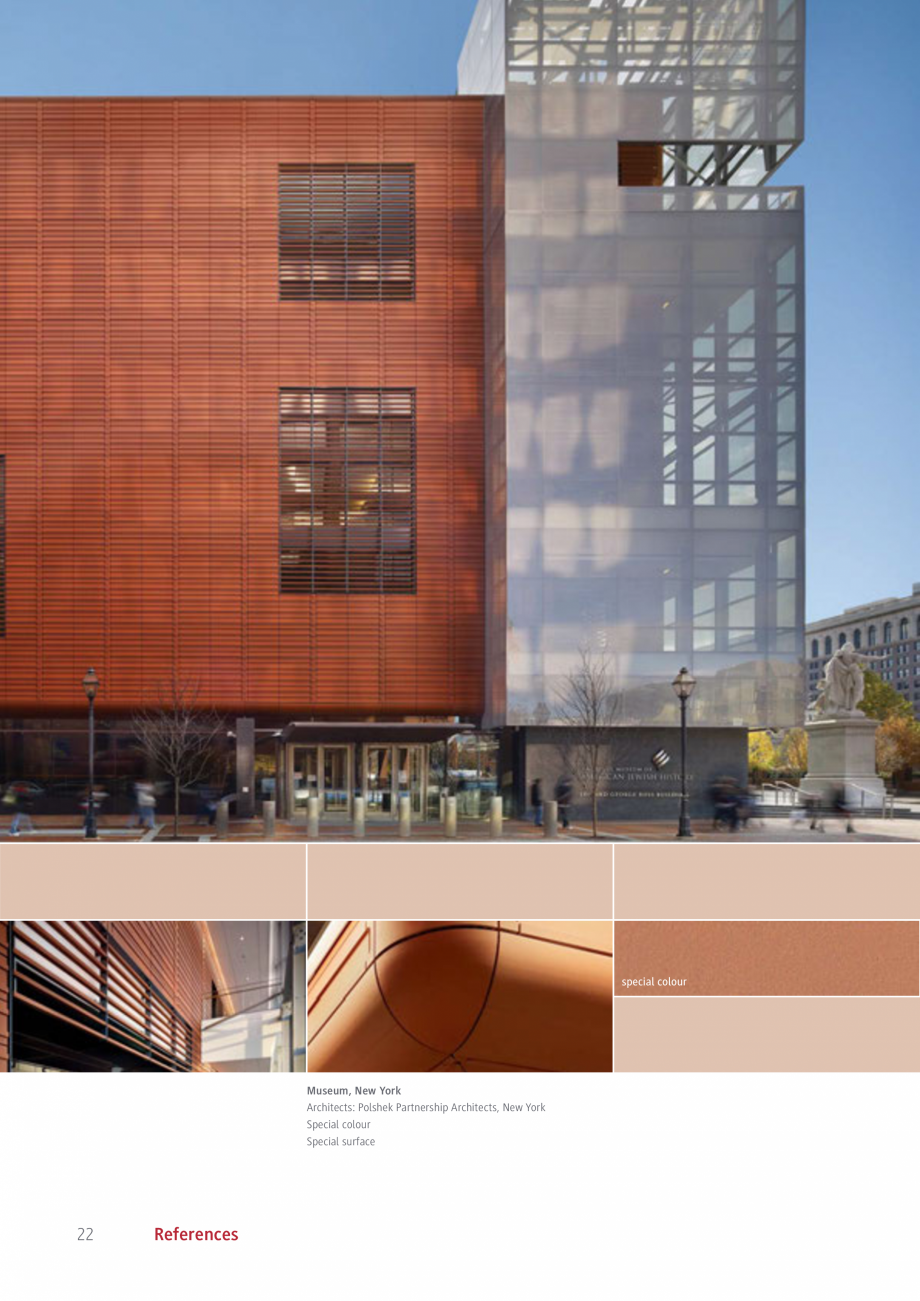

Placi ceramice pentru fatada MOEDING LONGOTON

Alte documentatii ale aceleasi game Vezi toate

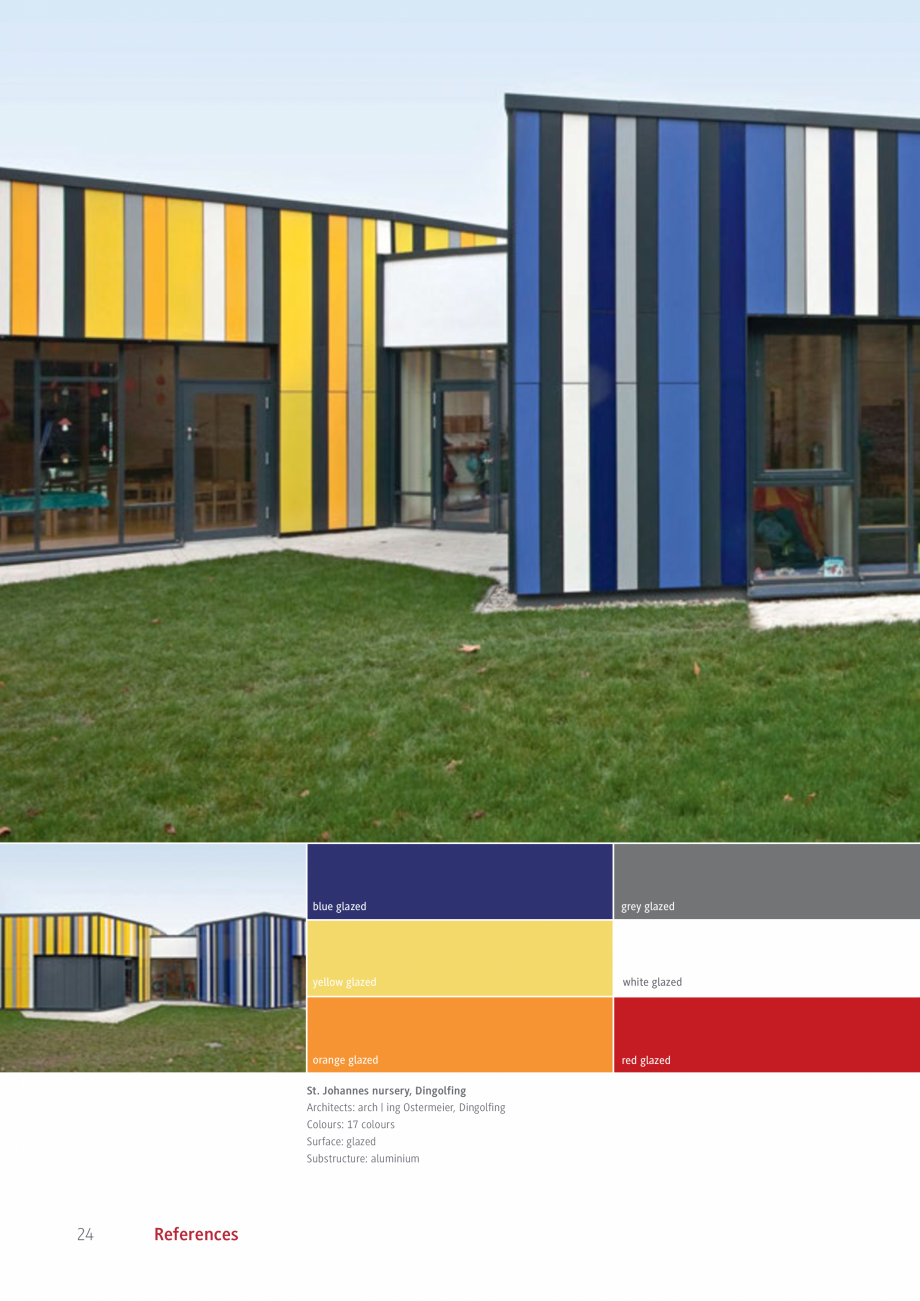

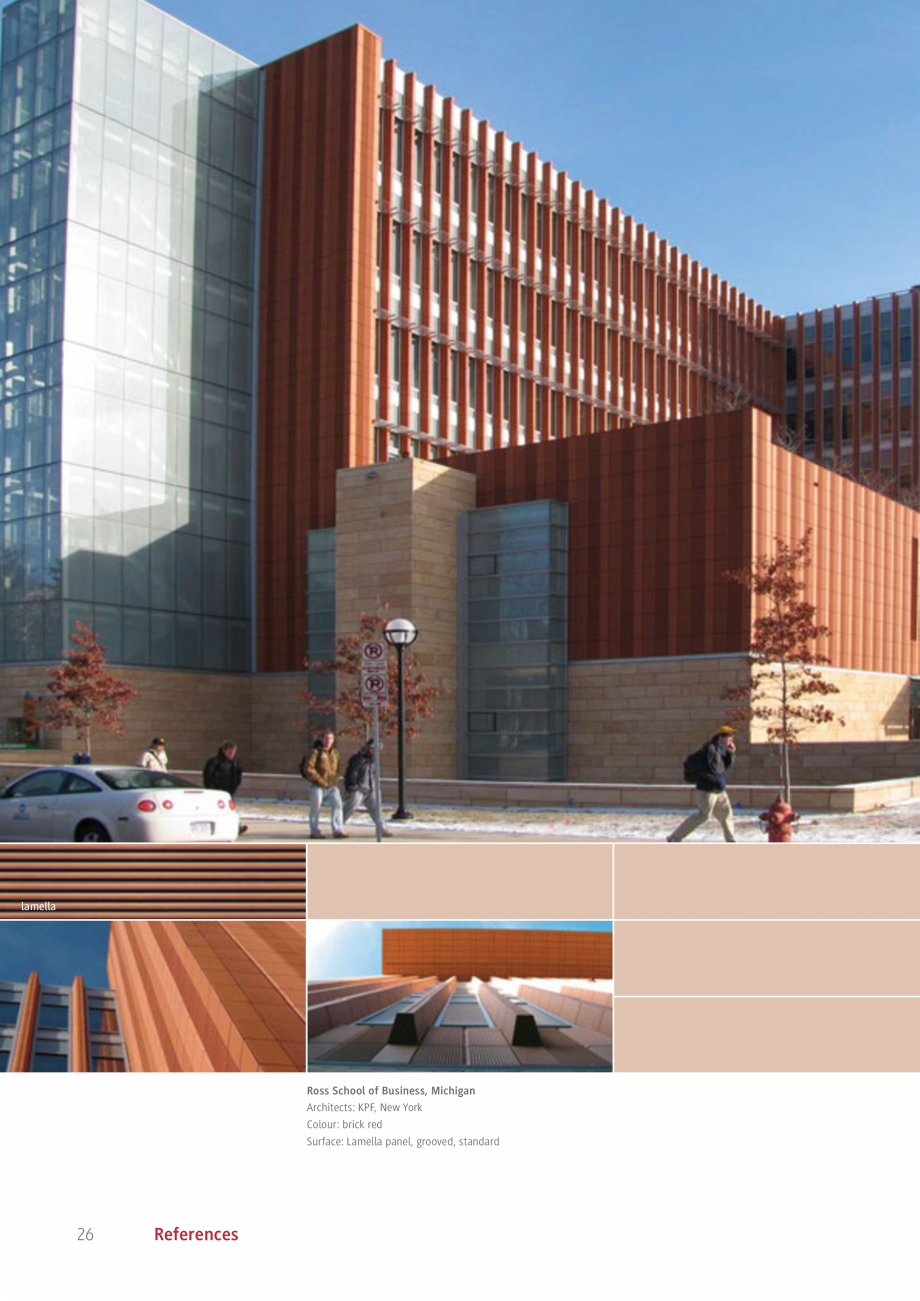

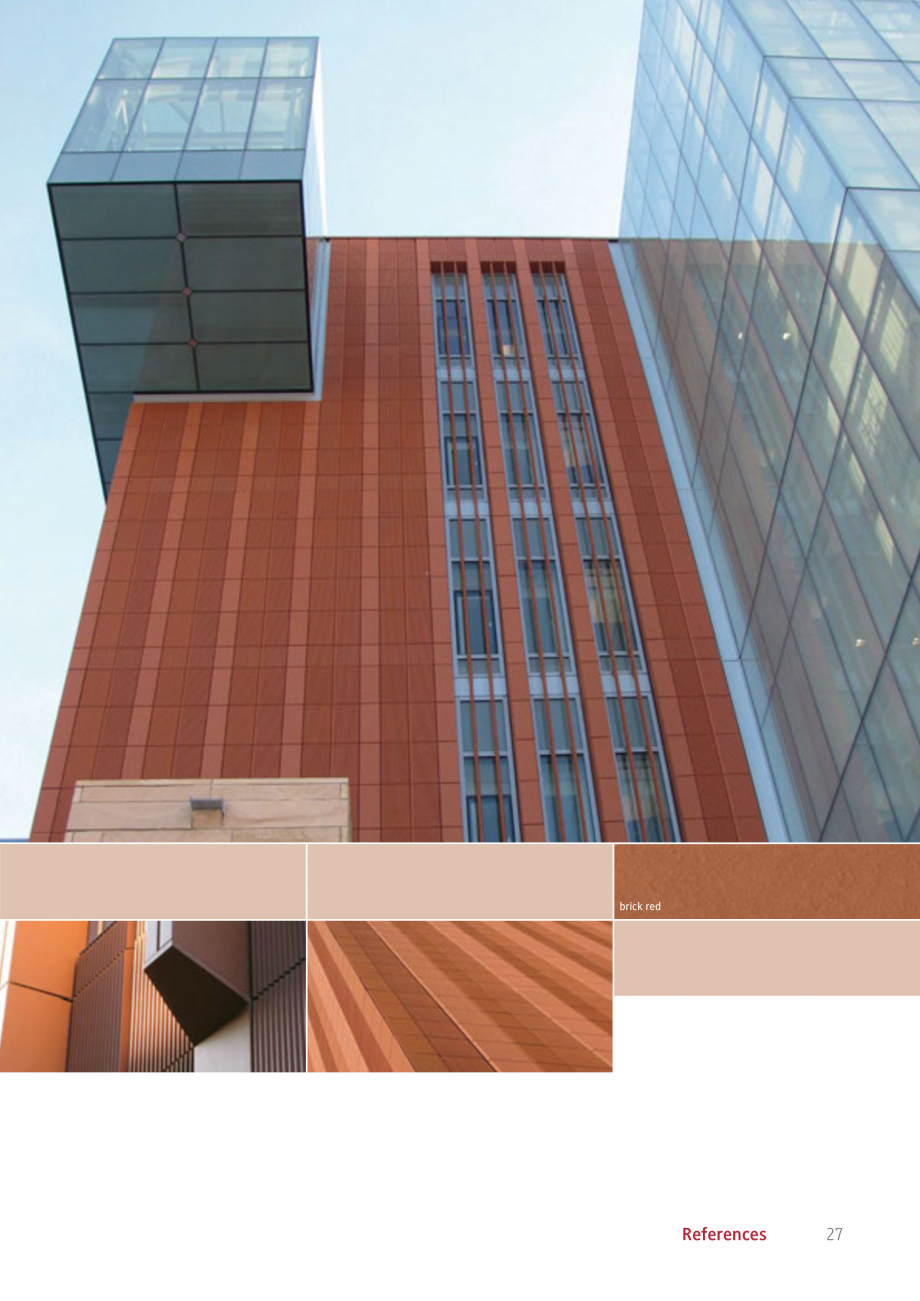

Lucrari, proiecte

15 p | EN

ALPHATON

Fisa tehnica

9 p | EN

ALPHATON