Pompe de caldura Aer-Apa MIDEA

Limba: Engleza

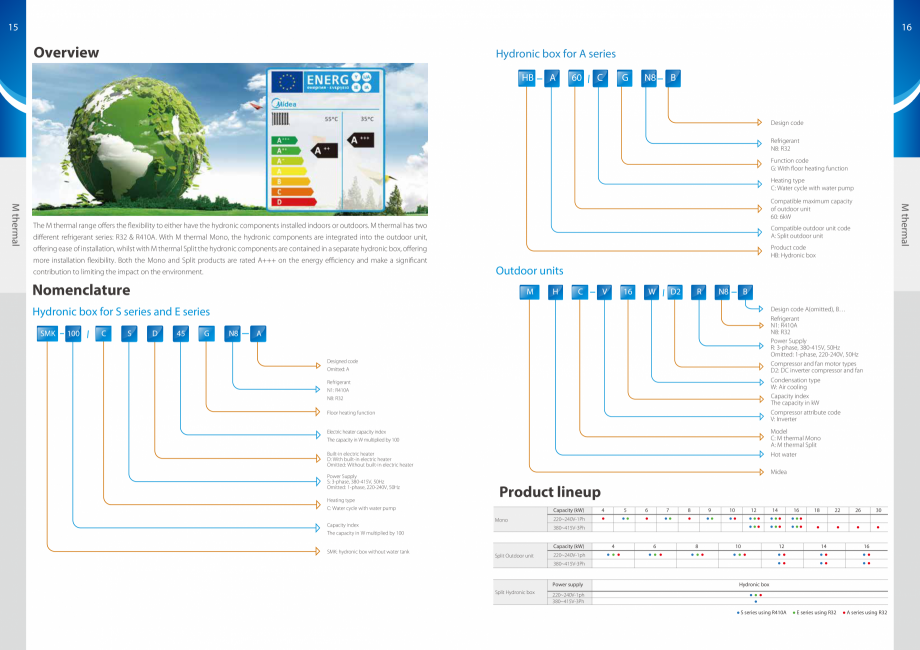

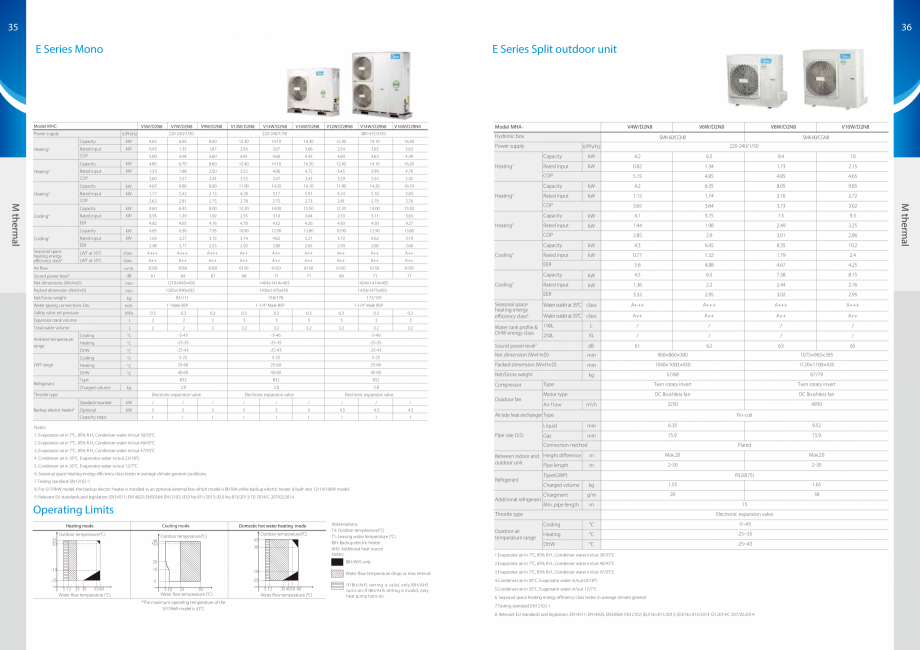

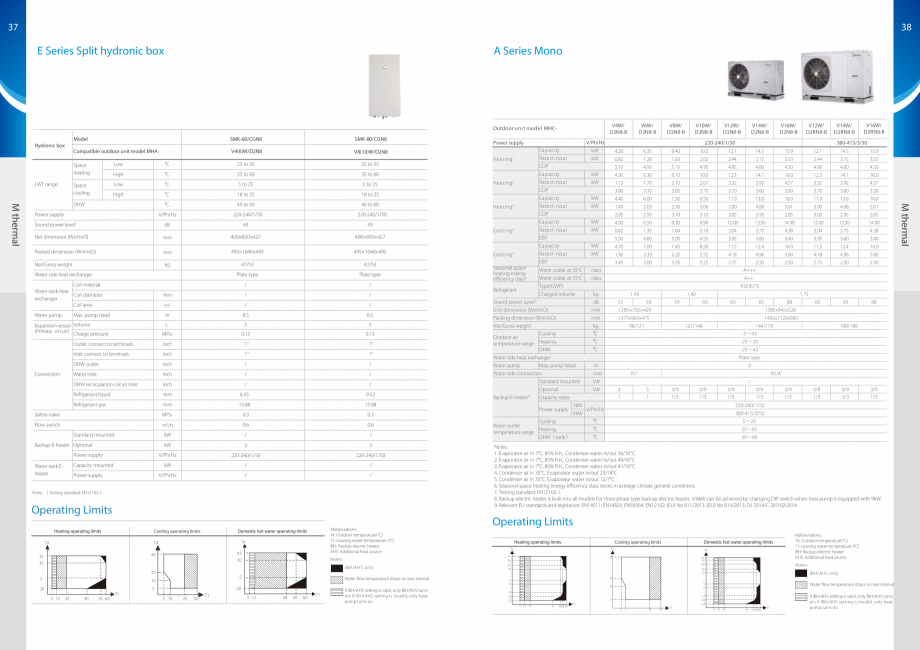

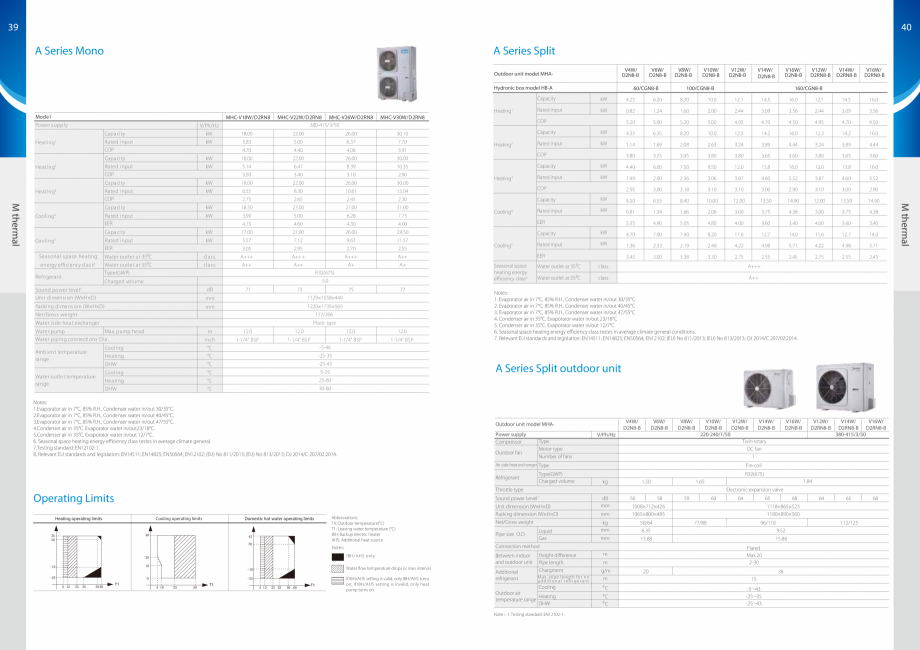

Produse încluse în această documentație: Monobloc 6 kW, Monobloc 8 kW, Monobloc 10 kW, Monobloc 12 kW, Split 6 kW, Split 8 kW, Split 10 kW, Split 12 kW, Split 16 kW

6

6

7

T

3 4

5

9

8

3

8

7

7

FCU1

FHL2

FCUn

11

M

12

FHL2

FHLn

FHLn

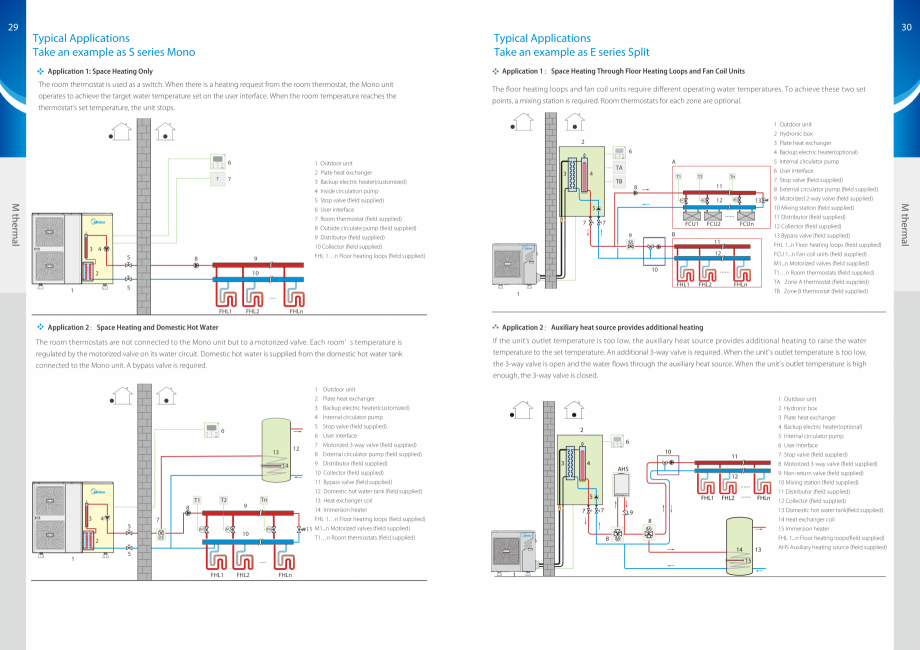

Application 2:Auxiliary heat source provides additional heating

6

12

13

14

T2

8

9

Tn

7

M2

M1

M

2

FCU2

B

9

1

The room thermostats are not connected to the Mono unit but to a motorized valve. Each room’ s temperature is

regulated by the motorized valve on its water circuit. Domestic hot water is supplied from the domestic hot water tank

connected to the Mono unit. A bypass valve is required.

5

13

Mn

10

Application 2:Space Heating and Domestic Hot Water

T1

12

M2

FHL1

FHL1

Tn

11

5

.......

4

T2

M1

5

1

1

T1

TB

10

2

3

A

TA

4

Mn

10

If the unit’s outlet temperature is too low, the auxiliary heat source provides additional heating to raise the water

temperature to the set temperature. An additional 3-way valve is required. When the unit’s outlet temperature is too low,

the 3-way valve is open and the water flows through the auxiliary heat source. When the unit

... ascunde