Prezentare generala - Panouri compozite din aluminiu ALUCOBOND ALUCOBOND® A2, ALUCOBOND® Plus, ALUCORE®

erior and interior.

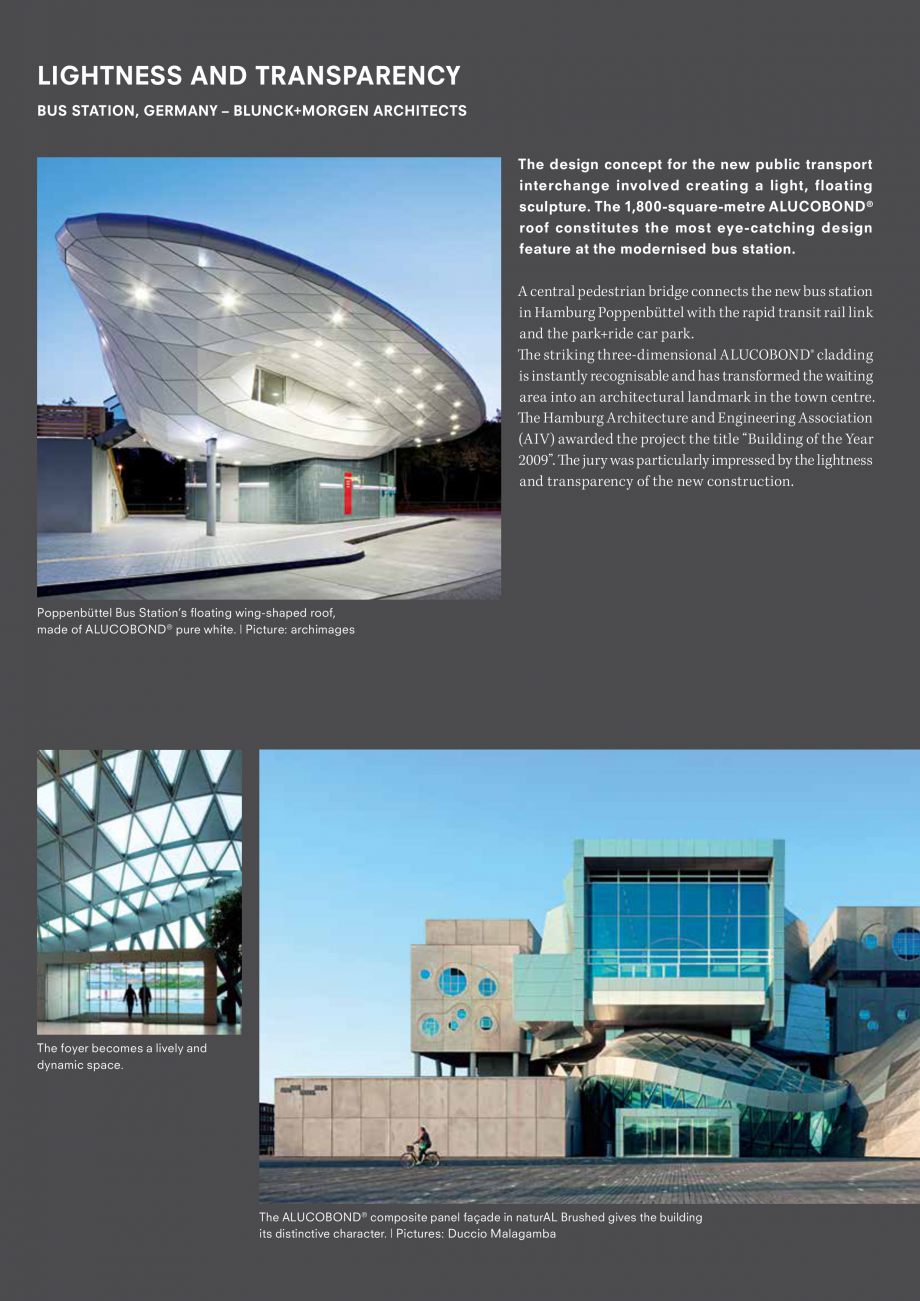

Viennese architecture office, Coop Himmelb(l)au designed the House of Music as a fusion between school and a concert hall, using an open-plan design to promote interaction

between audiences, artists, students and educators. According to Wolf. D. Prix, Design

Principal and CEO of Coop Himmelb(l)au, “The concept behind the building is evident from

its outer shape: the school embraces the concert hall. Our architecture acts just like an

instrument’s resonance chamber by magnifying the creativity within the House of Music.”

A concert hall seating 1,300 forms the core of the complex and is surrounded by a U-shaped

block containing rehearsal and teaching rooms. A spacious foyer with a multi-storey

glazed frontage links these rooms and overlooks the adjoining Cultural Plaza and nearby

fjord. Another three rooms of varying sizes are located under the foyer and offer additional space: the Intimate, the Rhythmic and the Classical hall. Students and visitors can

look in

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

Fisa tehnica