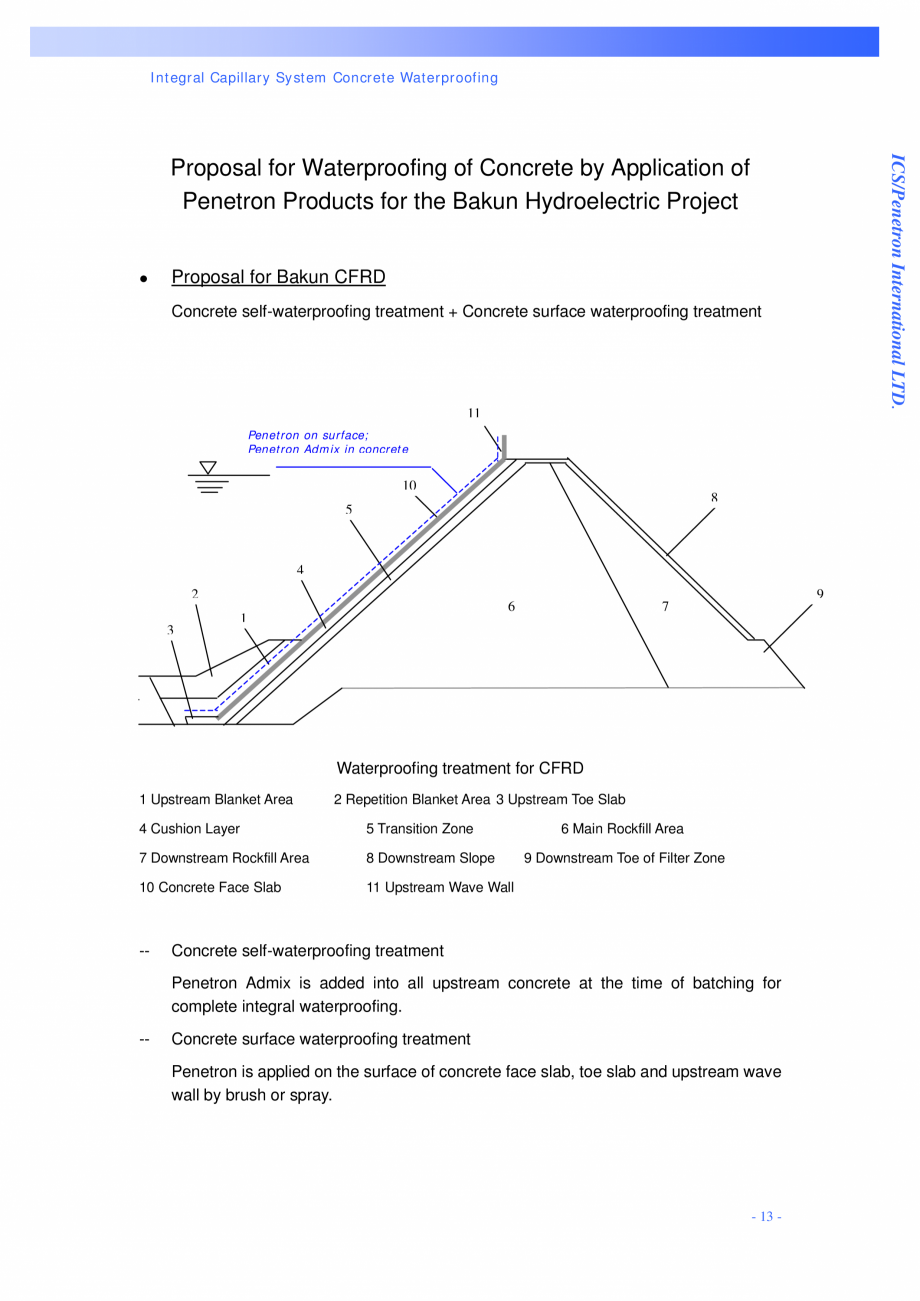

Proiectul hidroelectric Bakun PENETRON PENETRON, PENETRON ADMIX, PENETRON PLUS

Tip documentatie: Lucrari, proiecte

Salvează pdf

Full screen

capillary system.

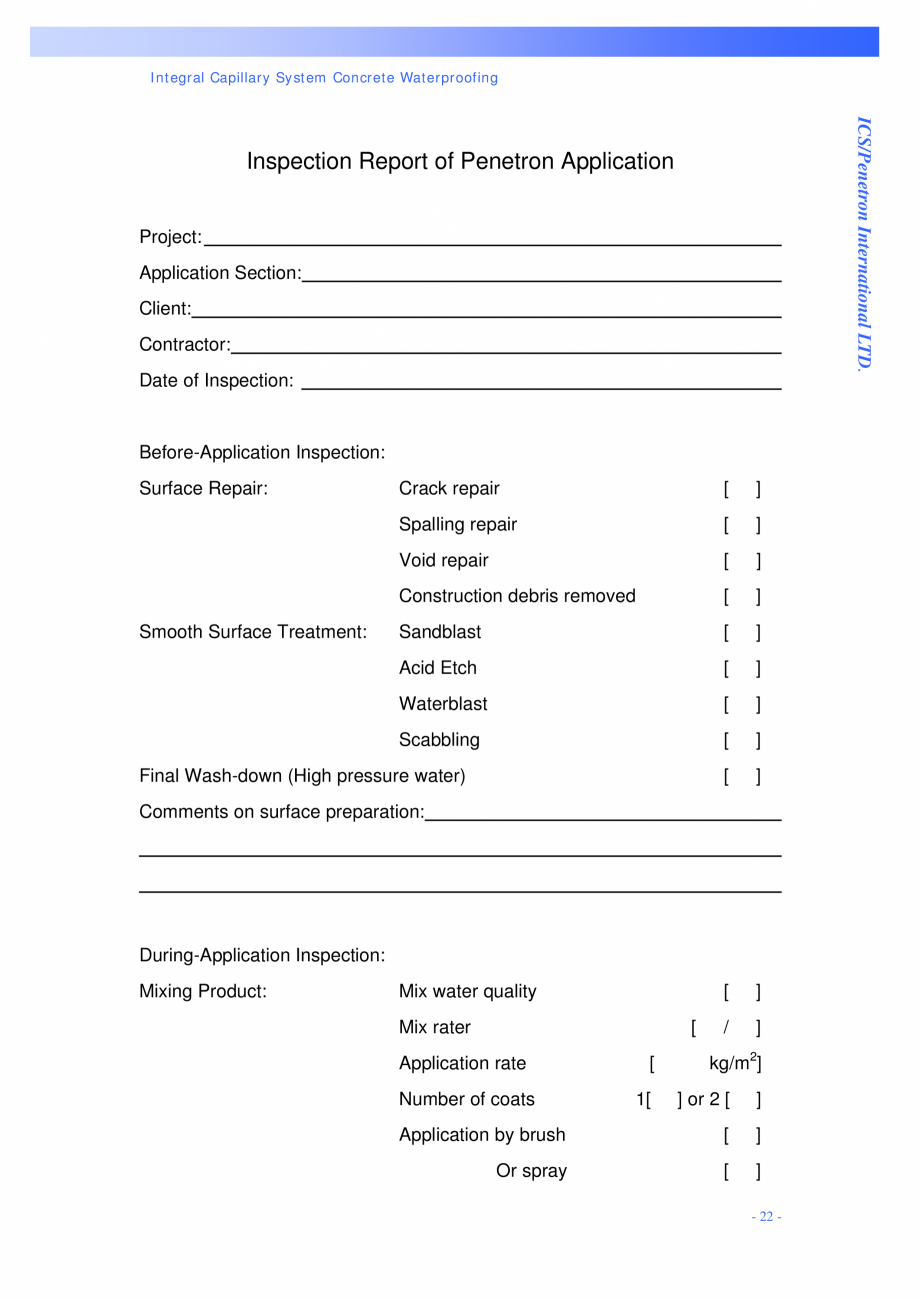

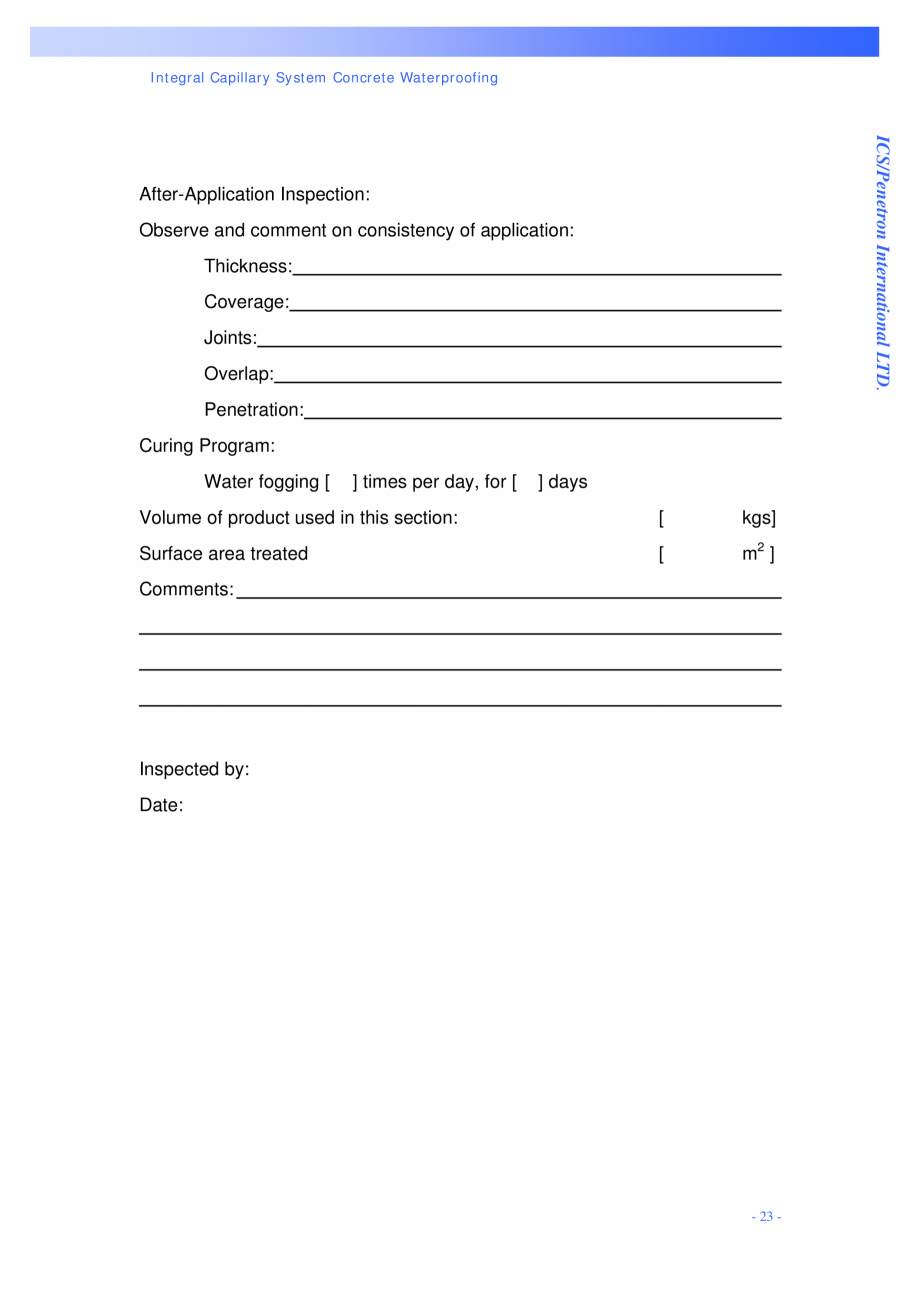

Rout out visible cracks exceeding 0.4mm in size to a depth of 20mm to 25mm. Also

rout out honeycombed pockets and faulty construction joints to sound concrete.

Construction joints are routed or provided with a formed 20mm*20mm reglet.

Wet down dry surfaces prior to the application of Penetron materials. Moisture must

be present in the concrete strata to ensure maximum chemical penetration. Surfaces

must be damp when Penetron products are applied.

--

Mixing

Brush application: 0.8-1.5kg/m2, 5 parts Penetron to 2 parts water

Spray application: 0.8-1.5kg/m2, 5 parts Penetron to 2.75-to-3.25 parts water (varies

with climate and spray equipment)

Penetron should be mixed to the consistency of thick latex paint. Stir the slurry

mixture frequently during the application and prepare only as much as can be applied

within a 30-minute period.

--

Application

Apply Penetron coating by masonry-type brush (artificial fibers, if available). For

spray application, drop hopper or pis

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

3 p |

PENETRON ADMIX

Fisa tehnica

2 p |

PENEPLUG