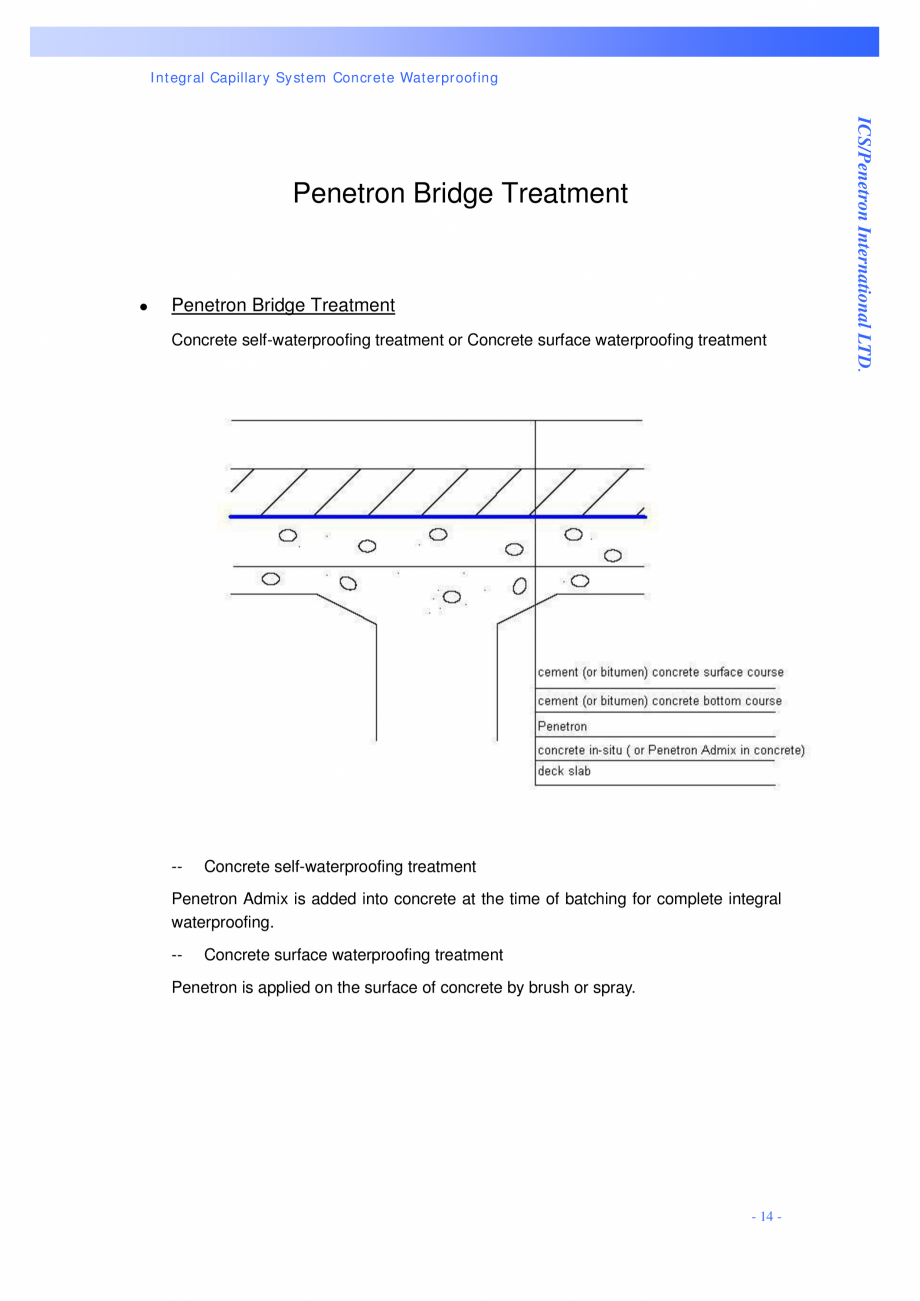

Structuri poduri PENETRON PENETRON, PENETRON ADMIX, PENETRON PLUS

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

3 p |

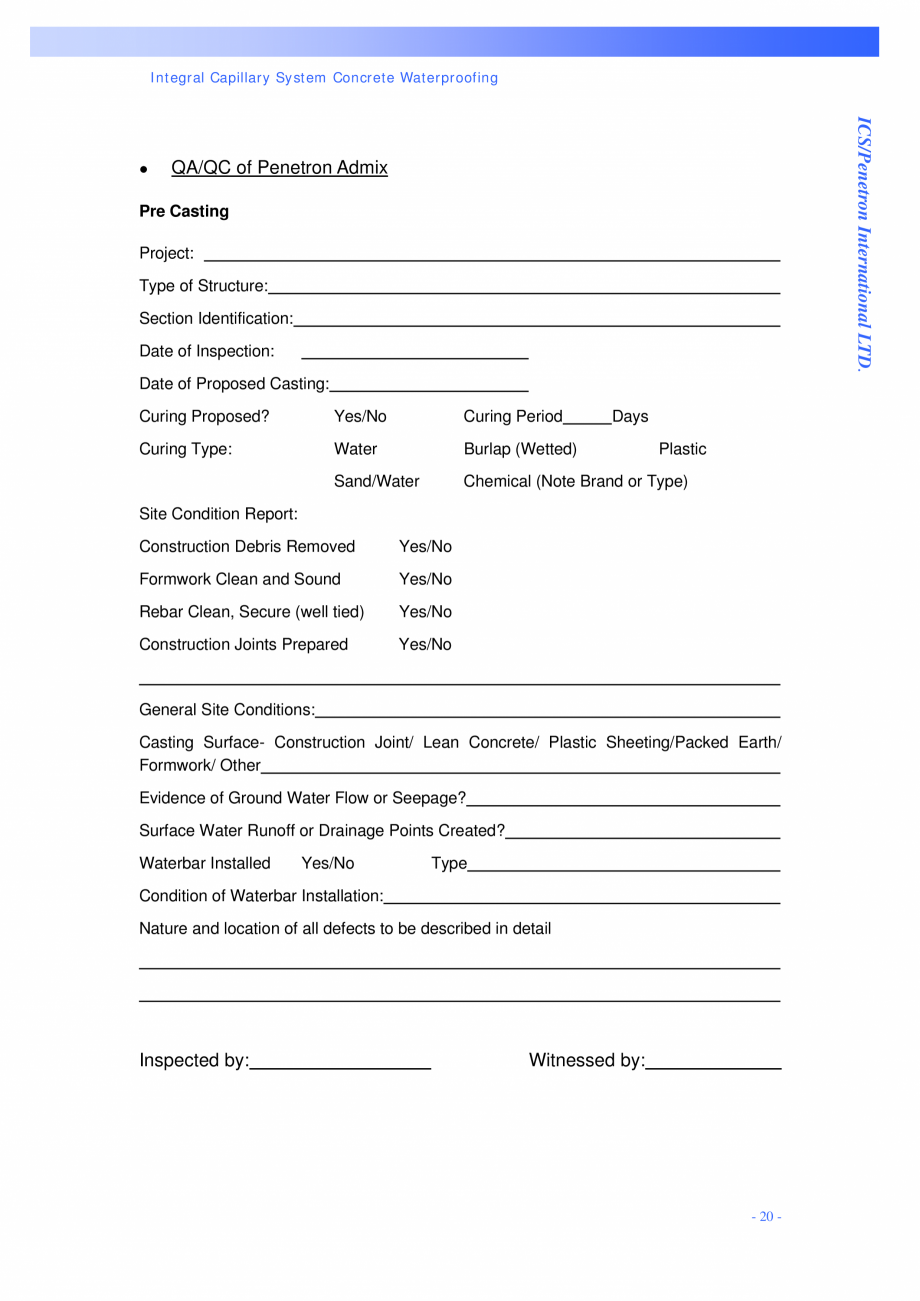

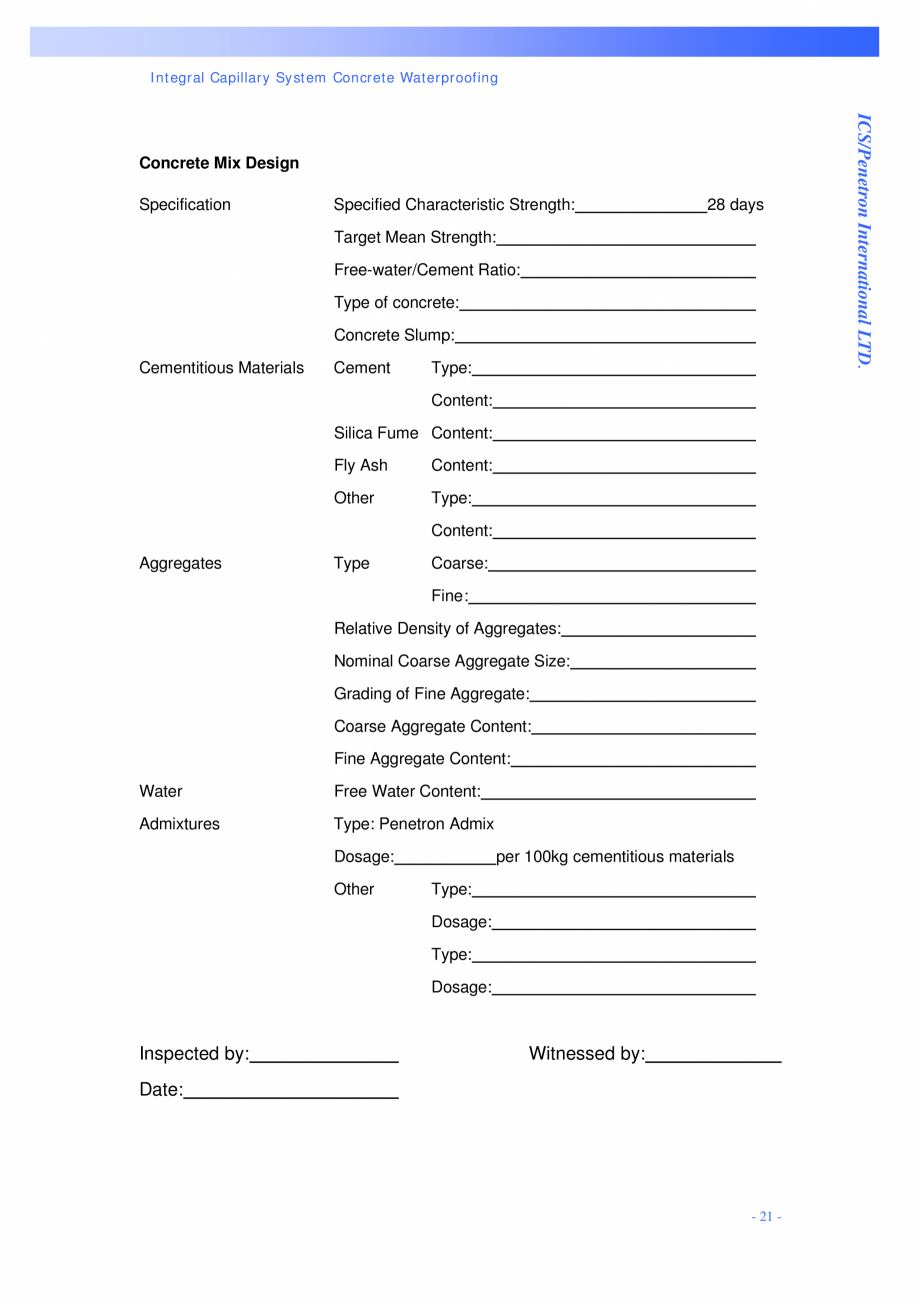

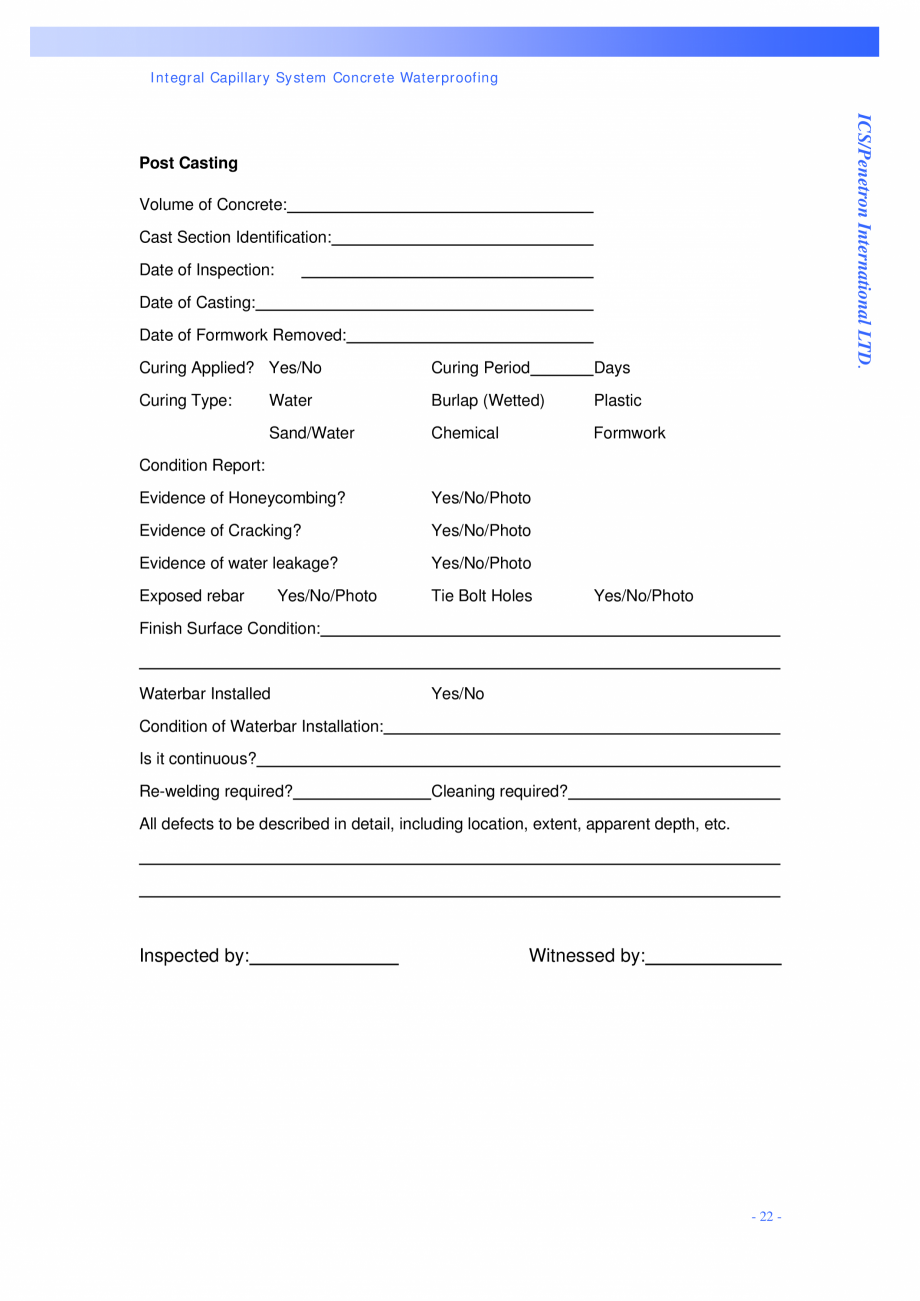

PENETRON ADMIX

Fisa tehnica

2 p |

PENEPLUG