Tubulatura textila - dispersia aerului FabricAir

Limba: Engleza

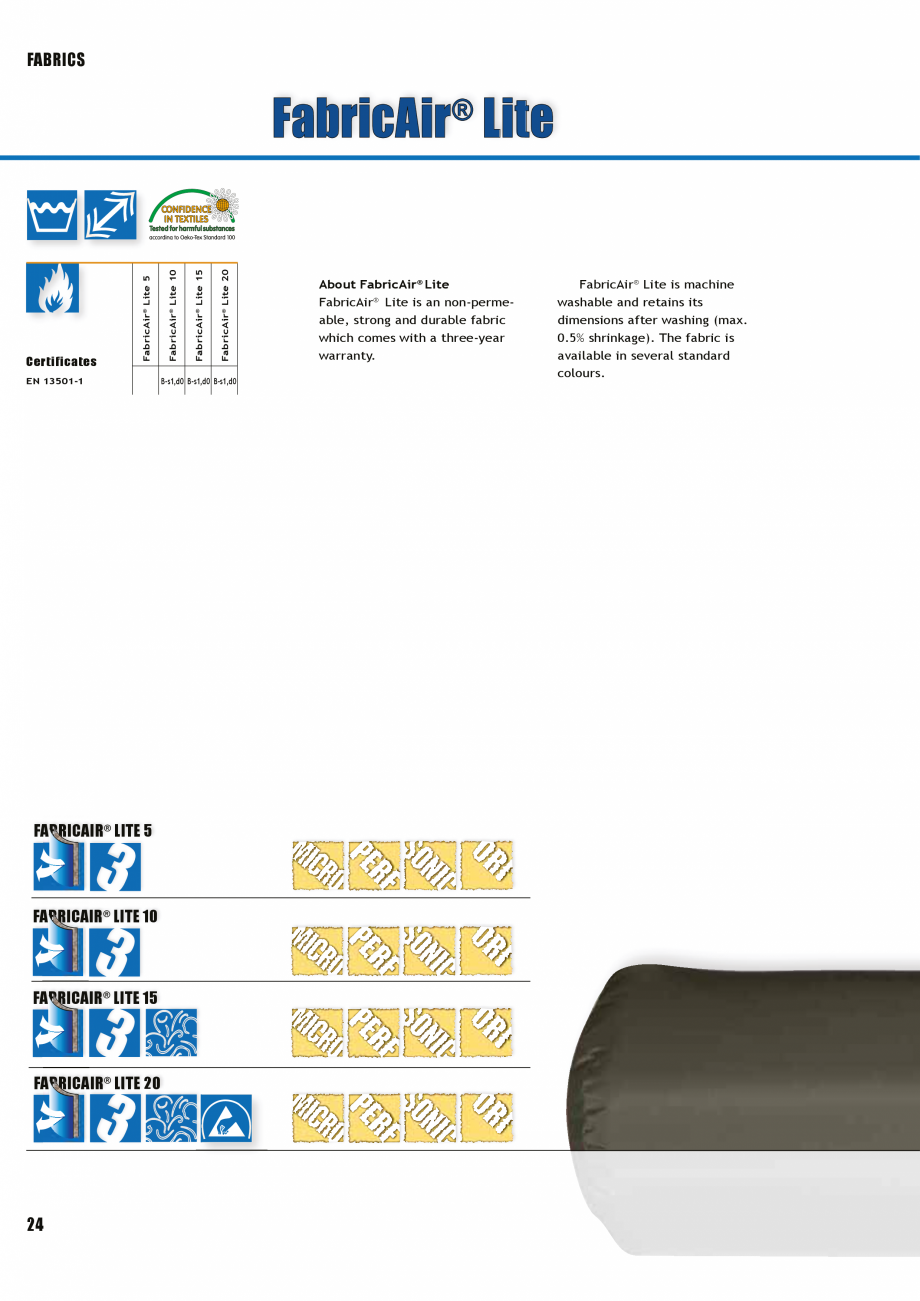

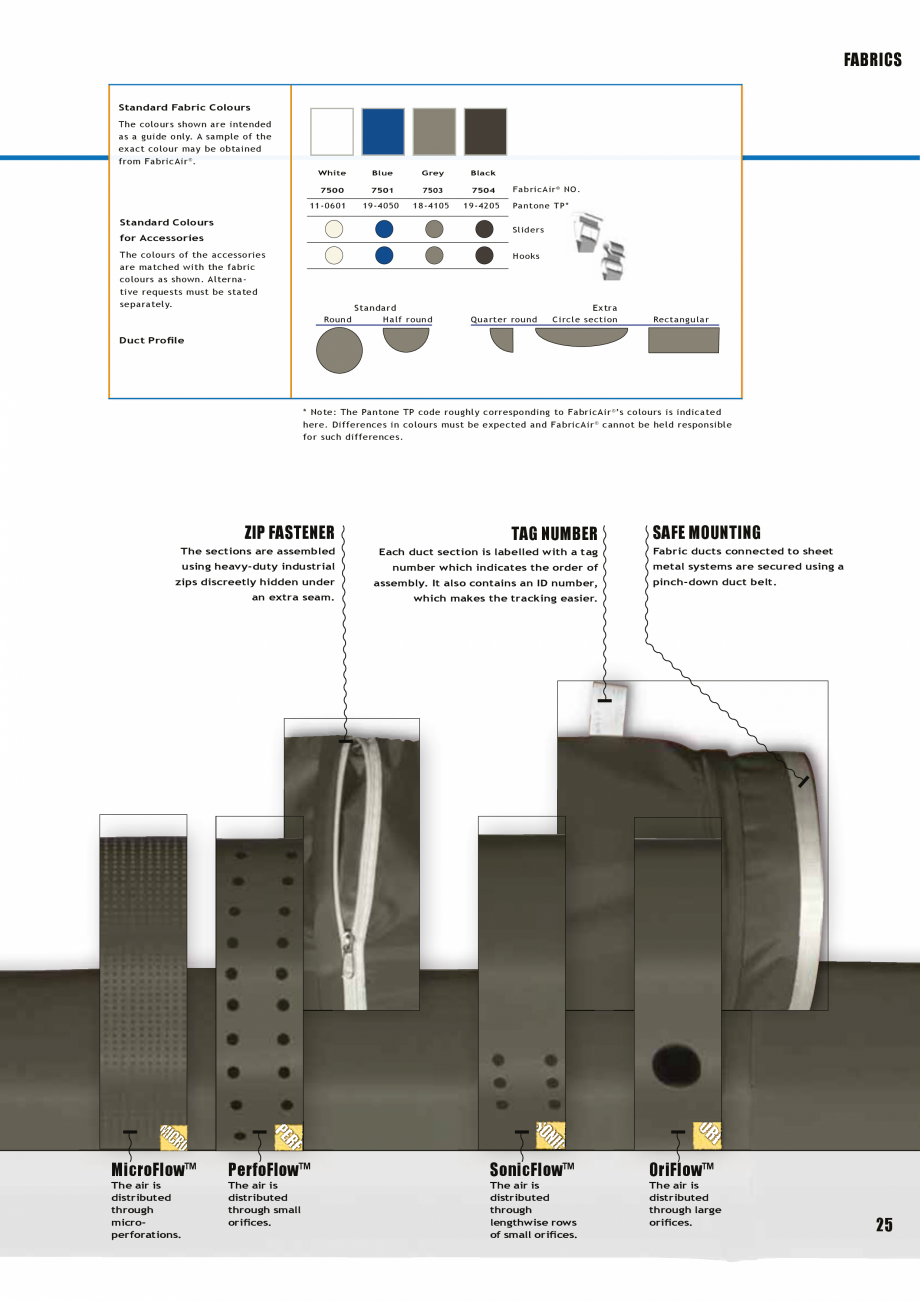

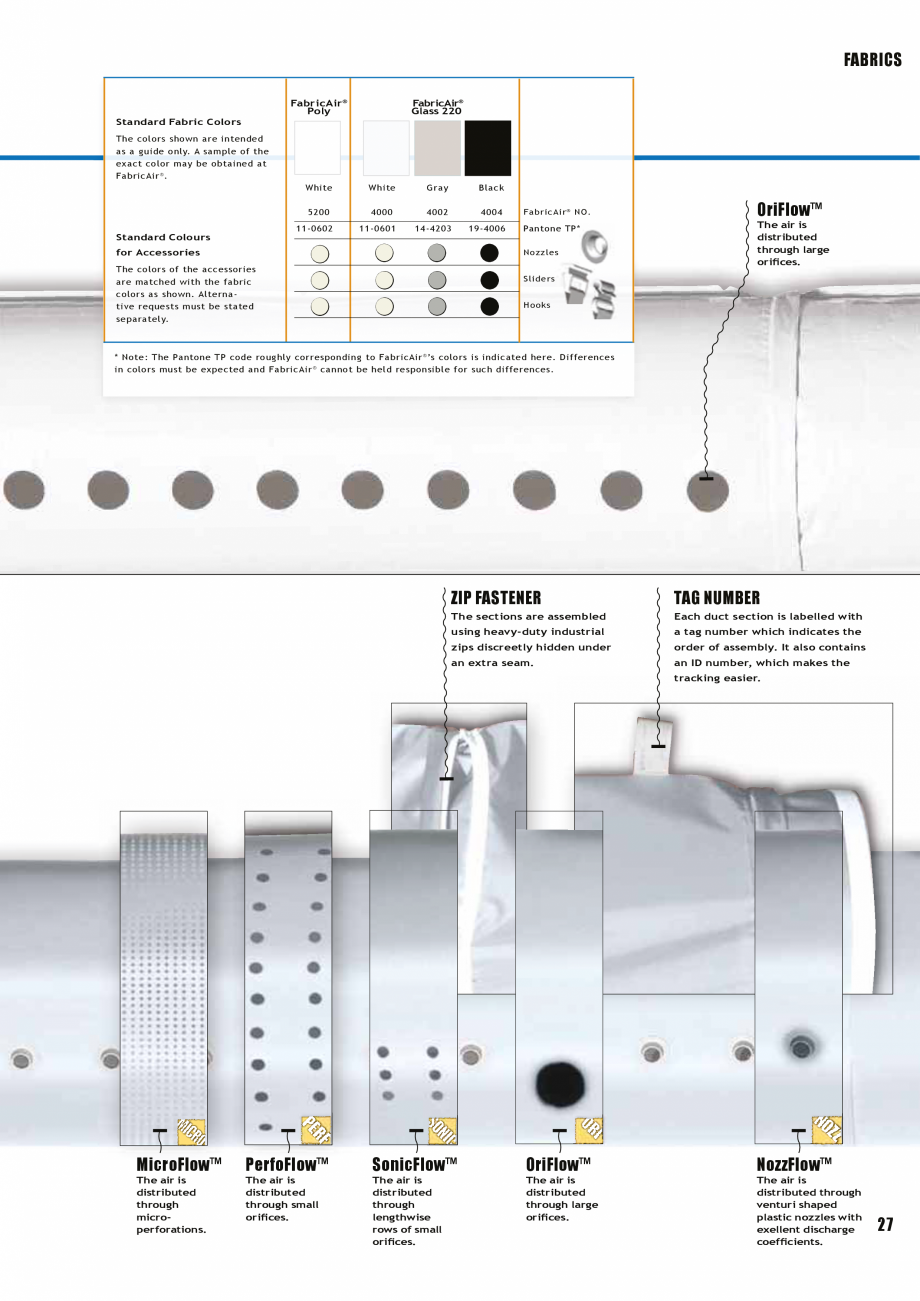

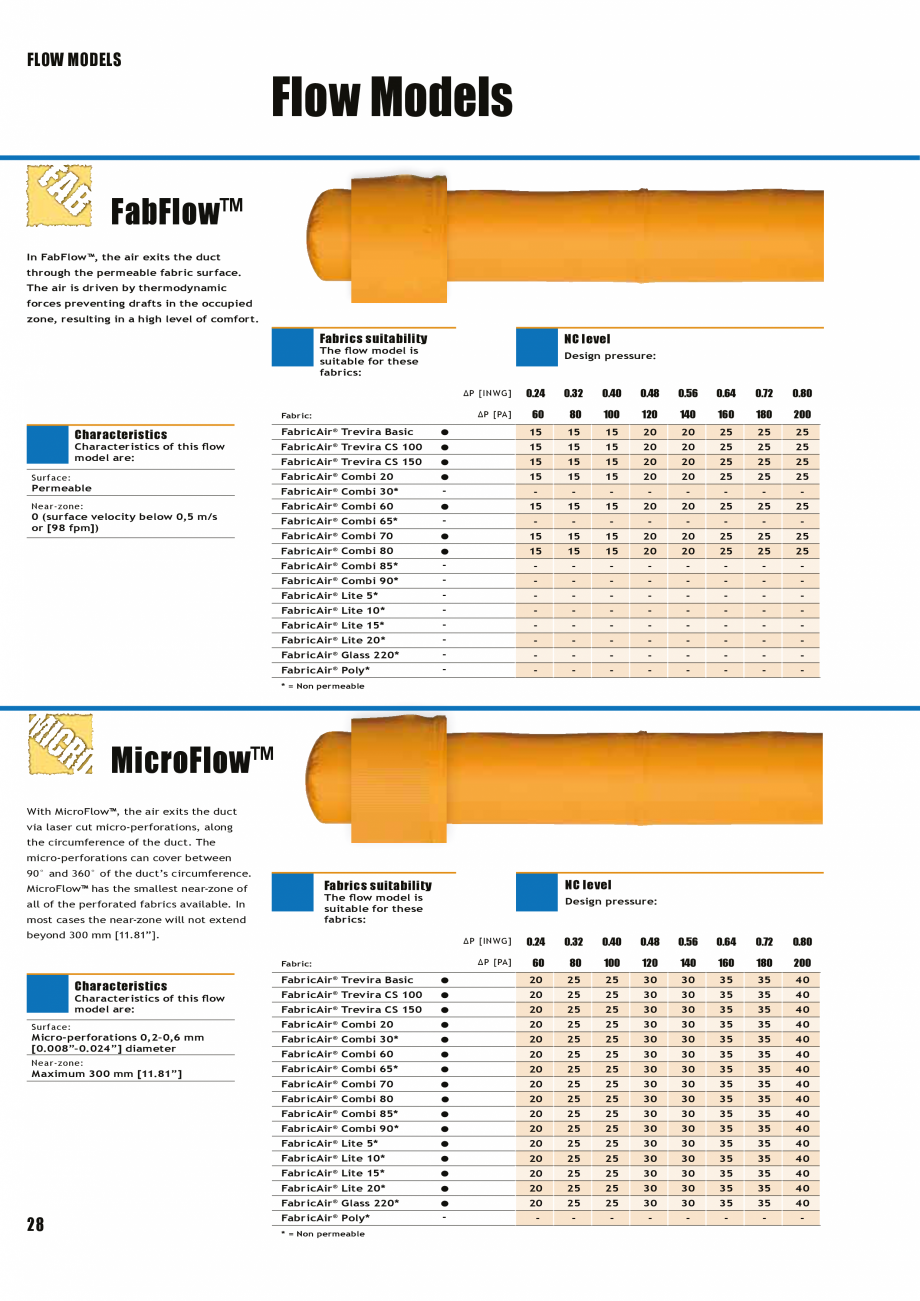

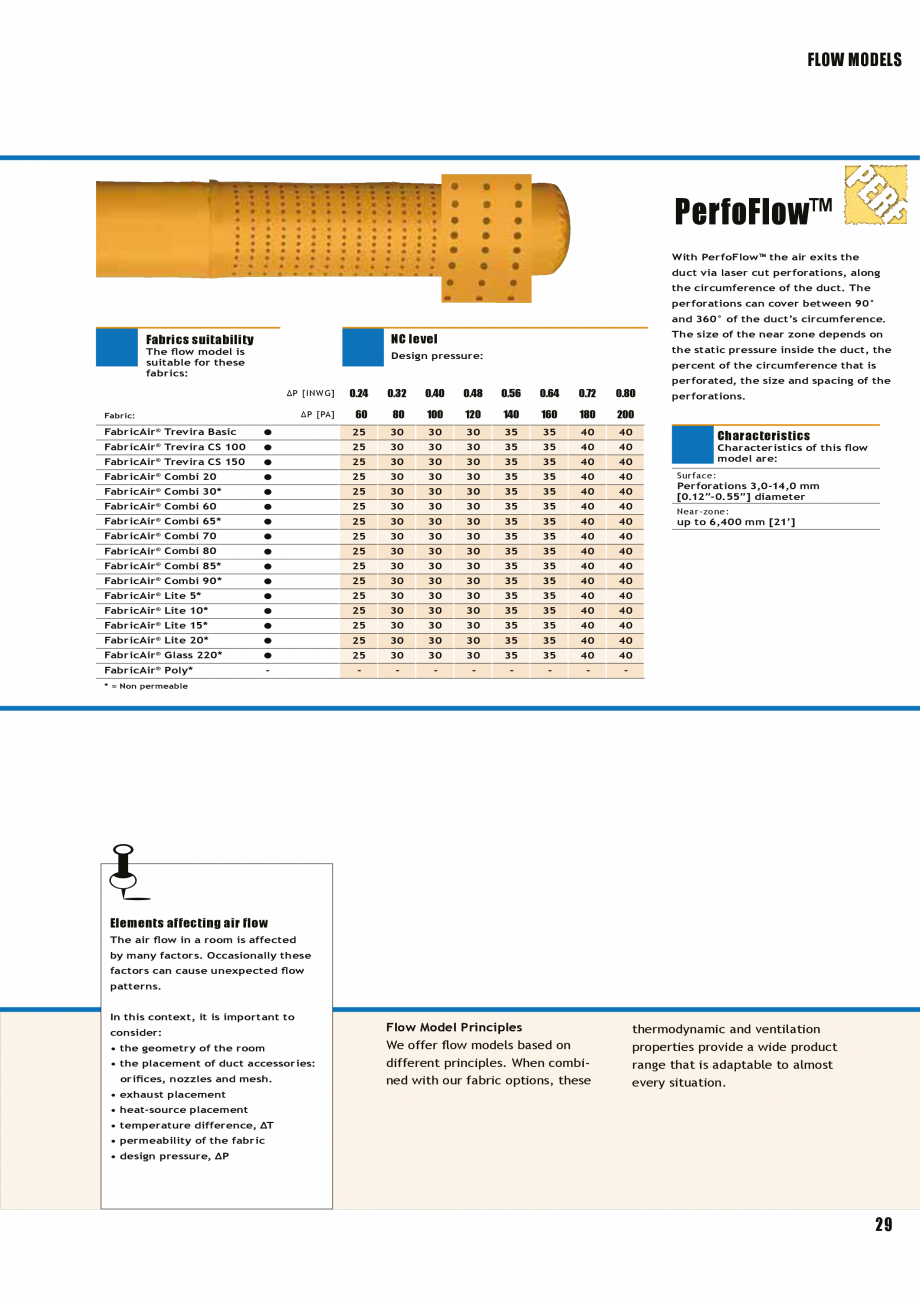

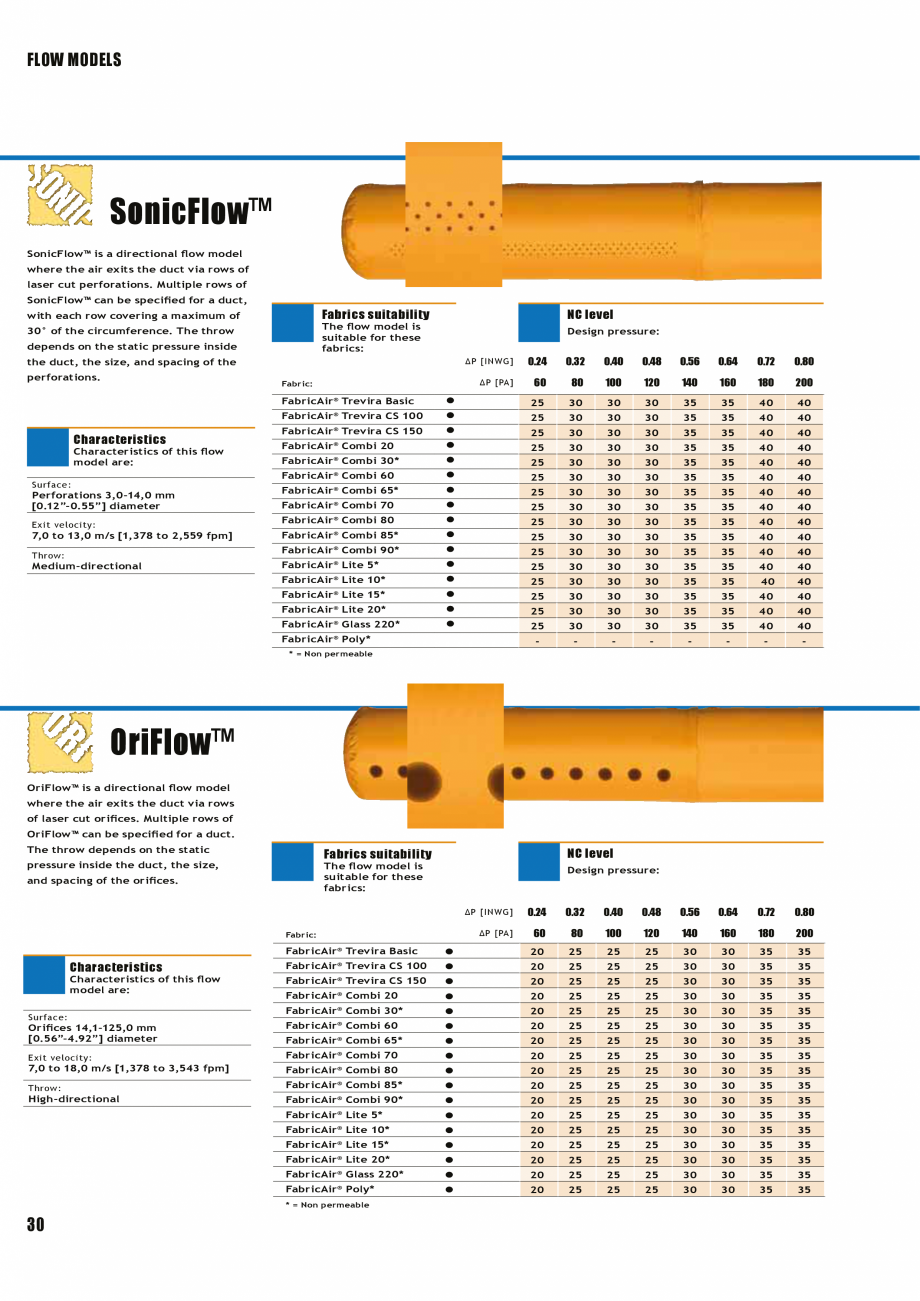

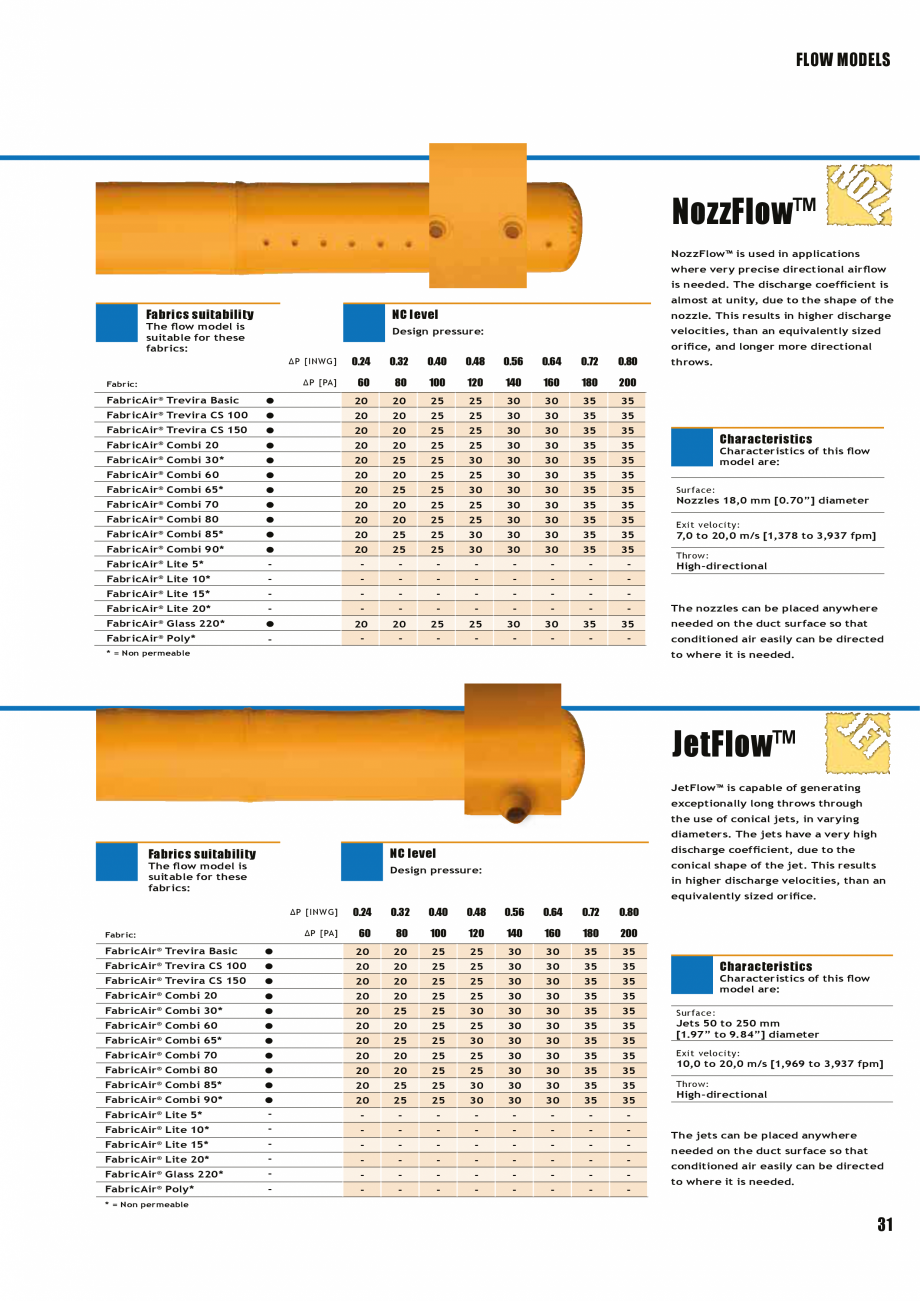

Produse încluse în această documentație: Trevira, Combi, Poly, AntiStat, Glass 220

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

4 p | EN

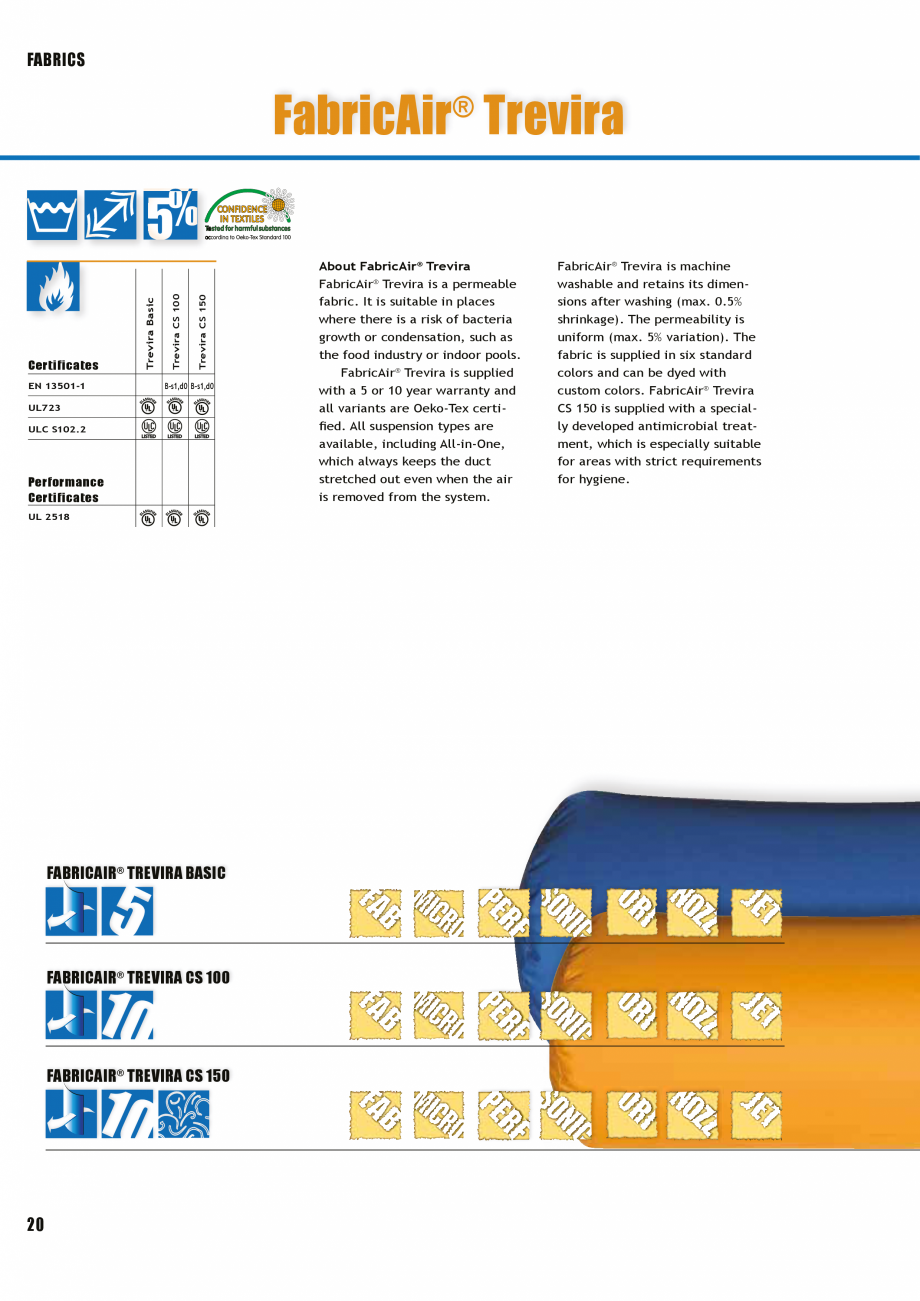

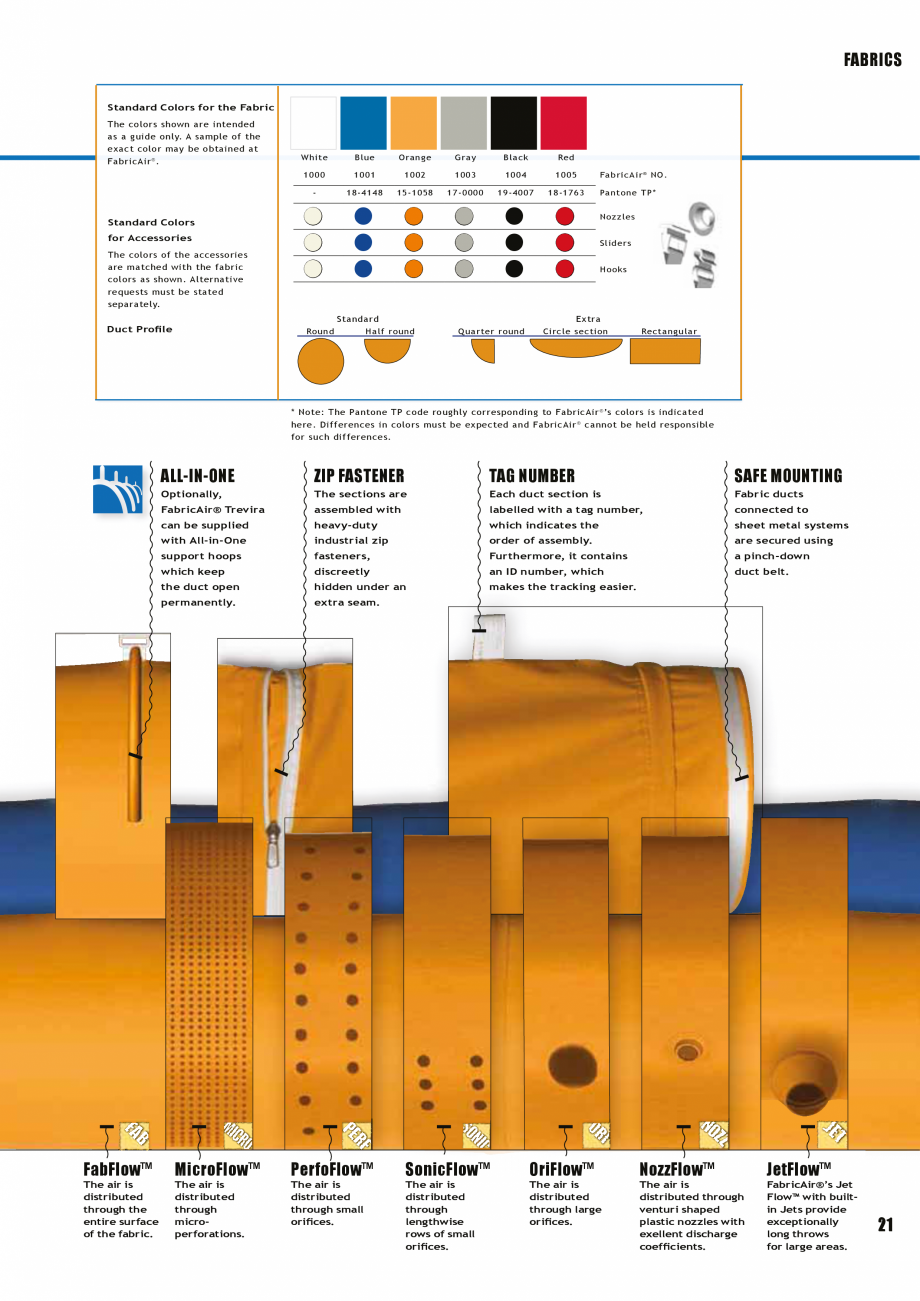

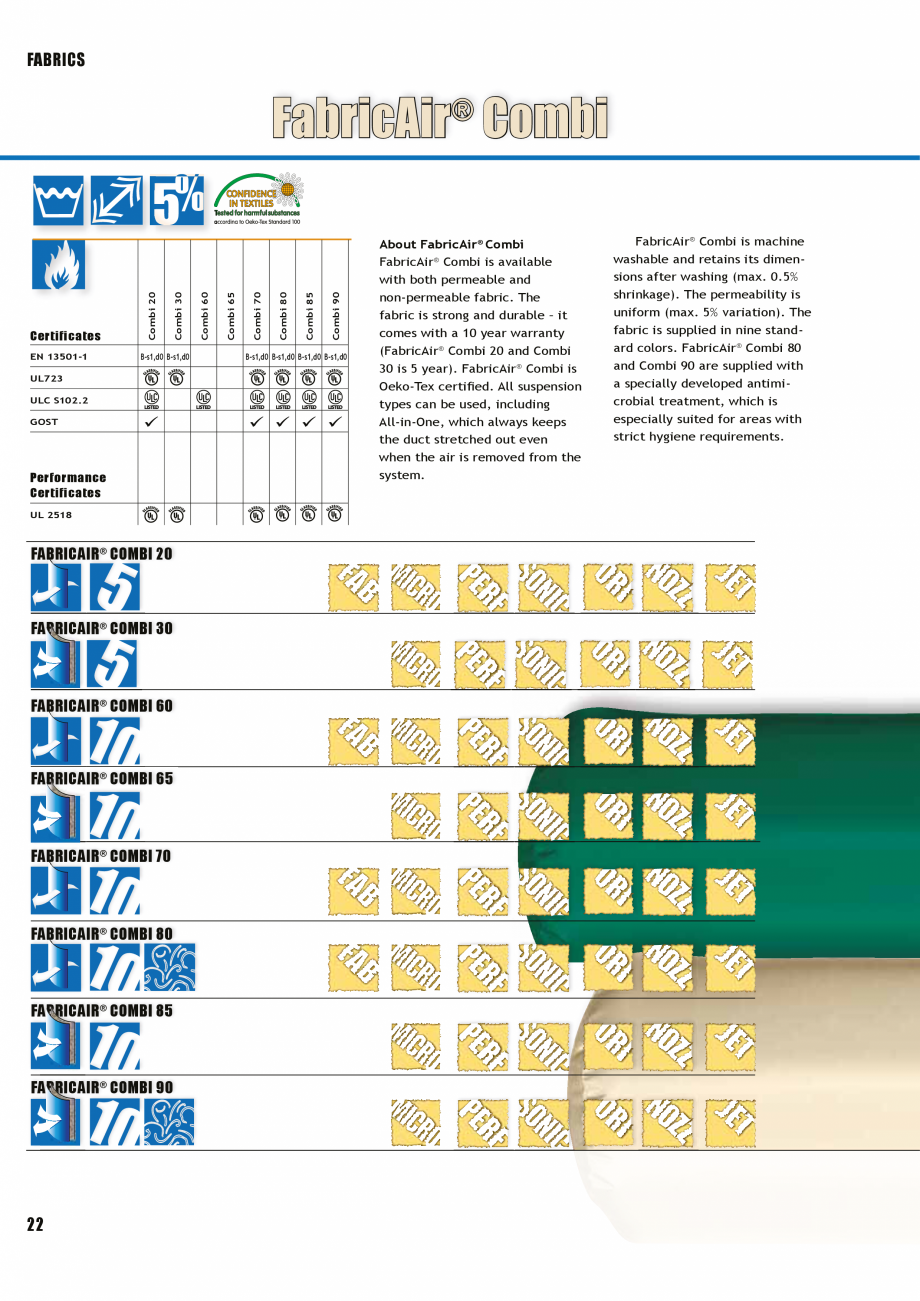

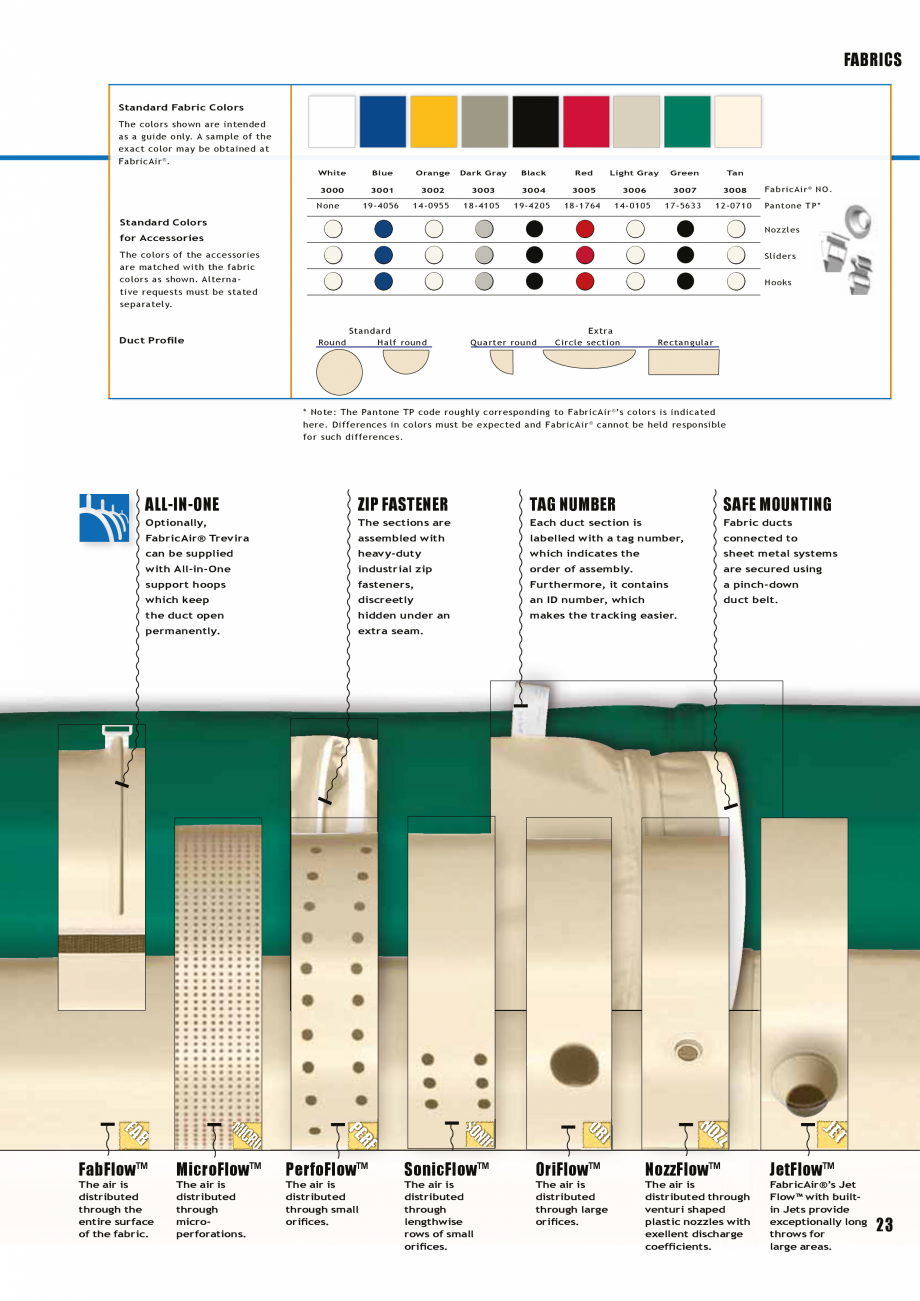

Trevira Combi Poly AntiStat Glass 220

Fisa tehnica

4 p | EN

Trevira