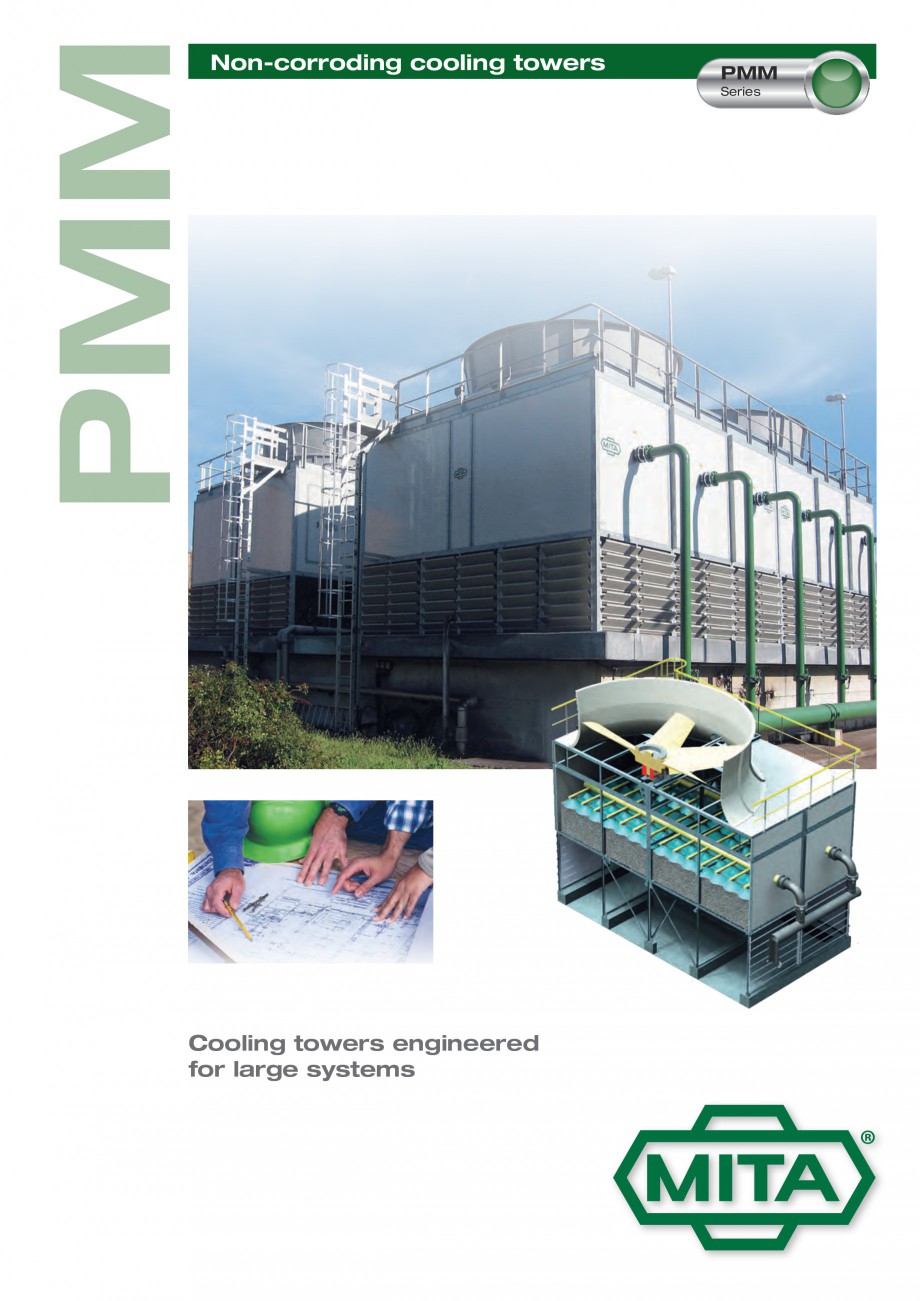

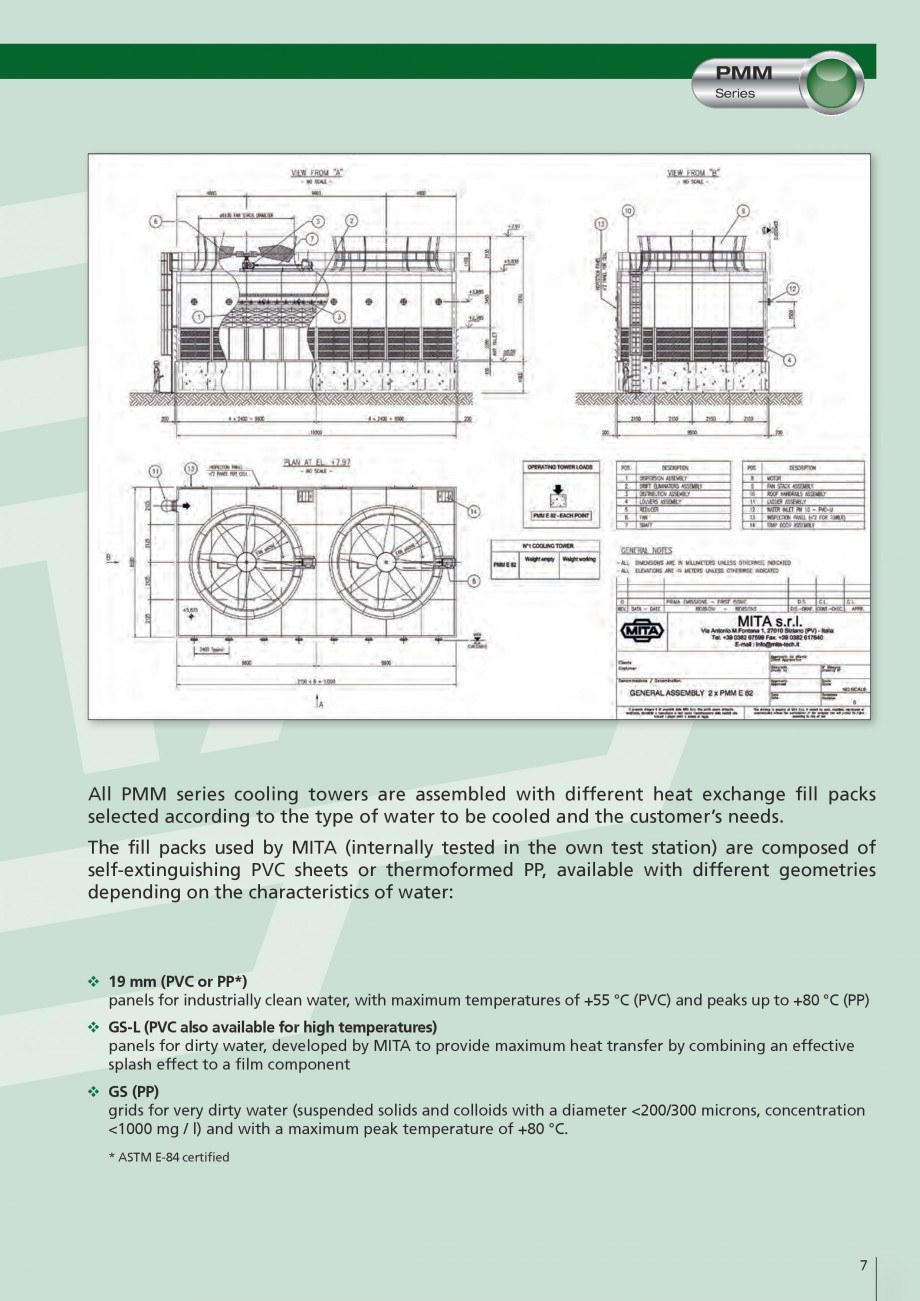

Turnuri de racire cu circuit deschis MITA PMM