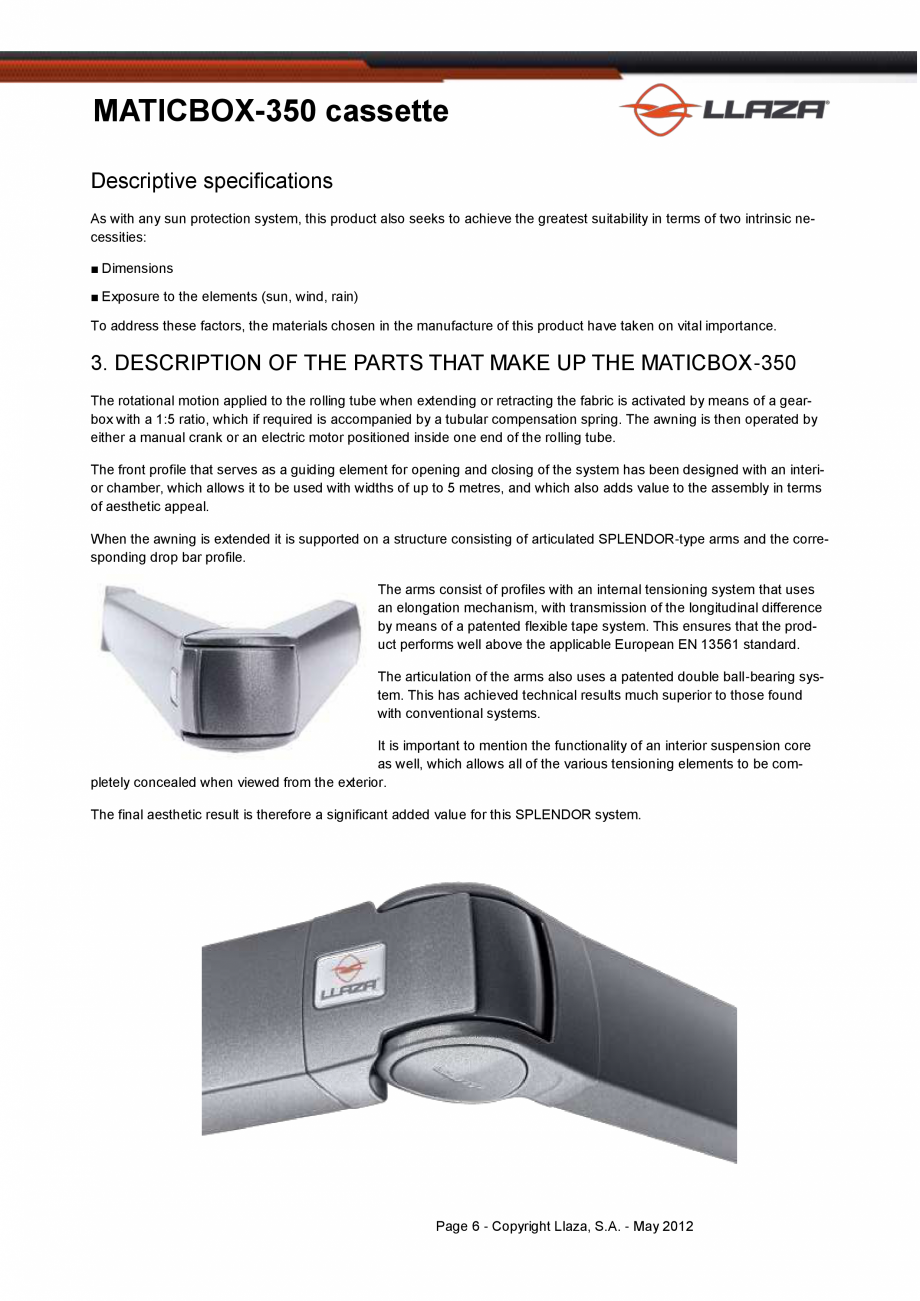

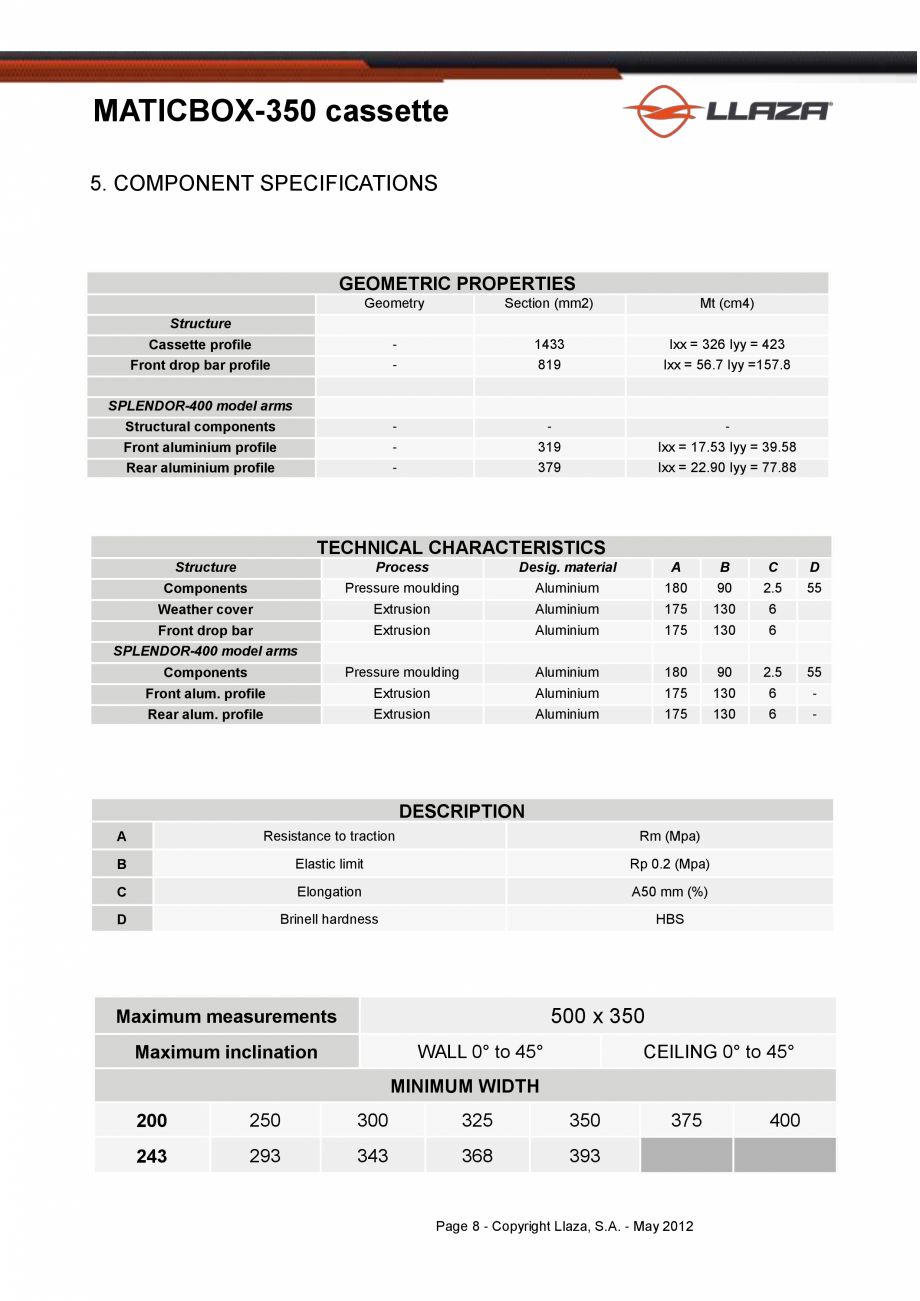

Copertina casetata de dimensiuni mai mici LLAZA MaticBox 350

Alte documentatii ale aceleasi game Vezi toate

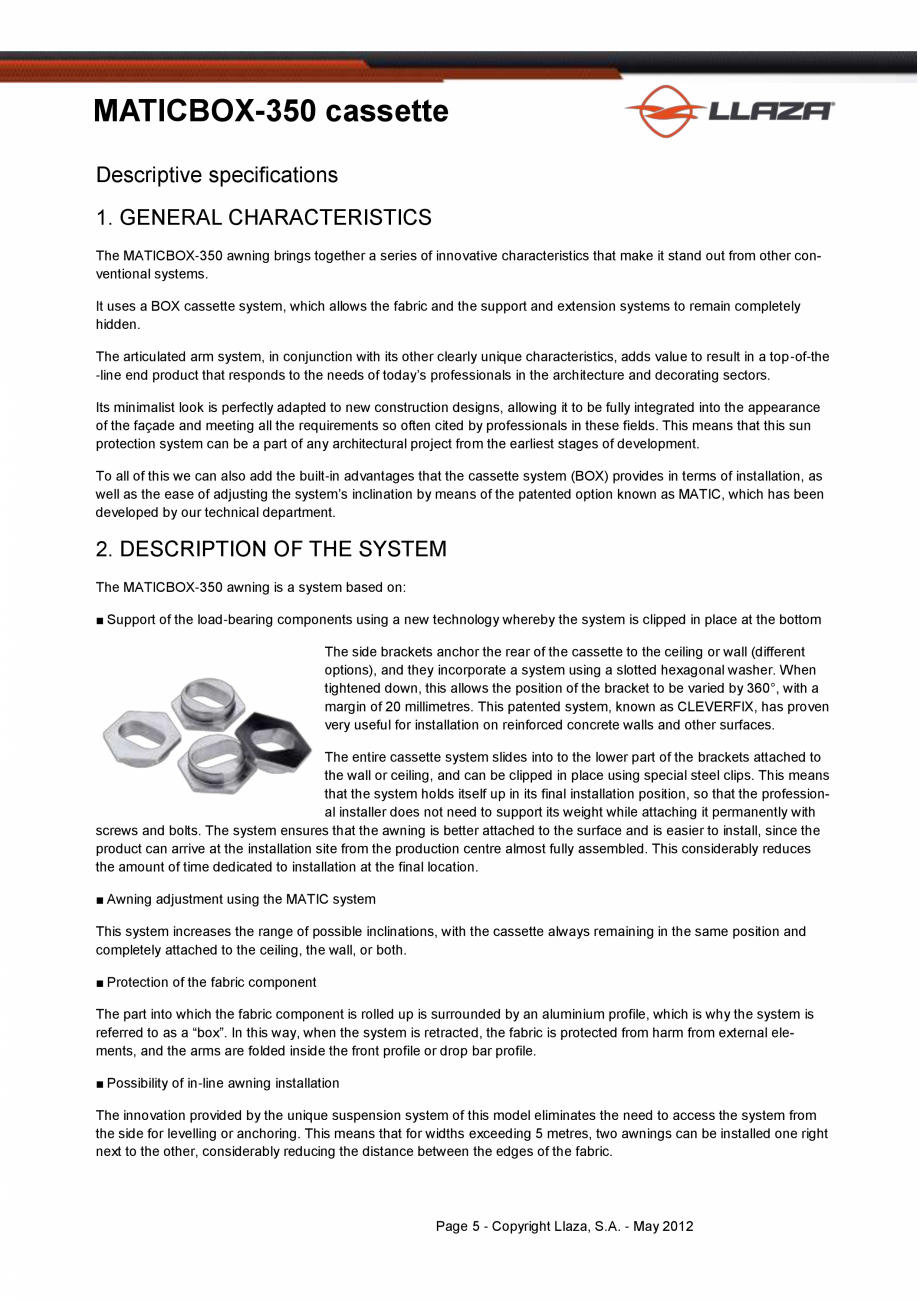

Instructiuni montaj, utilizare

12 p | EN - SP

StorBox 300

Instructiuni montaj, utilizare

12 p | EN - SP

StorBox 250