Copertina dubla cu ax comun si structura proprie LLAZA Duox

Alte documentatii ale aceleasi game Vezi toate

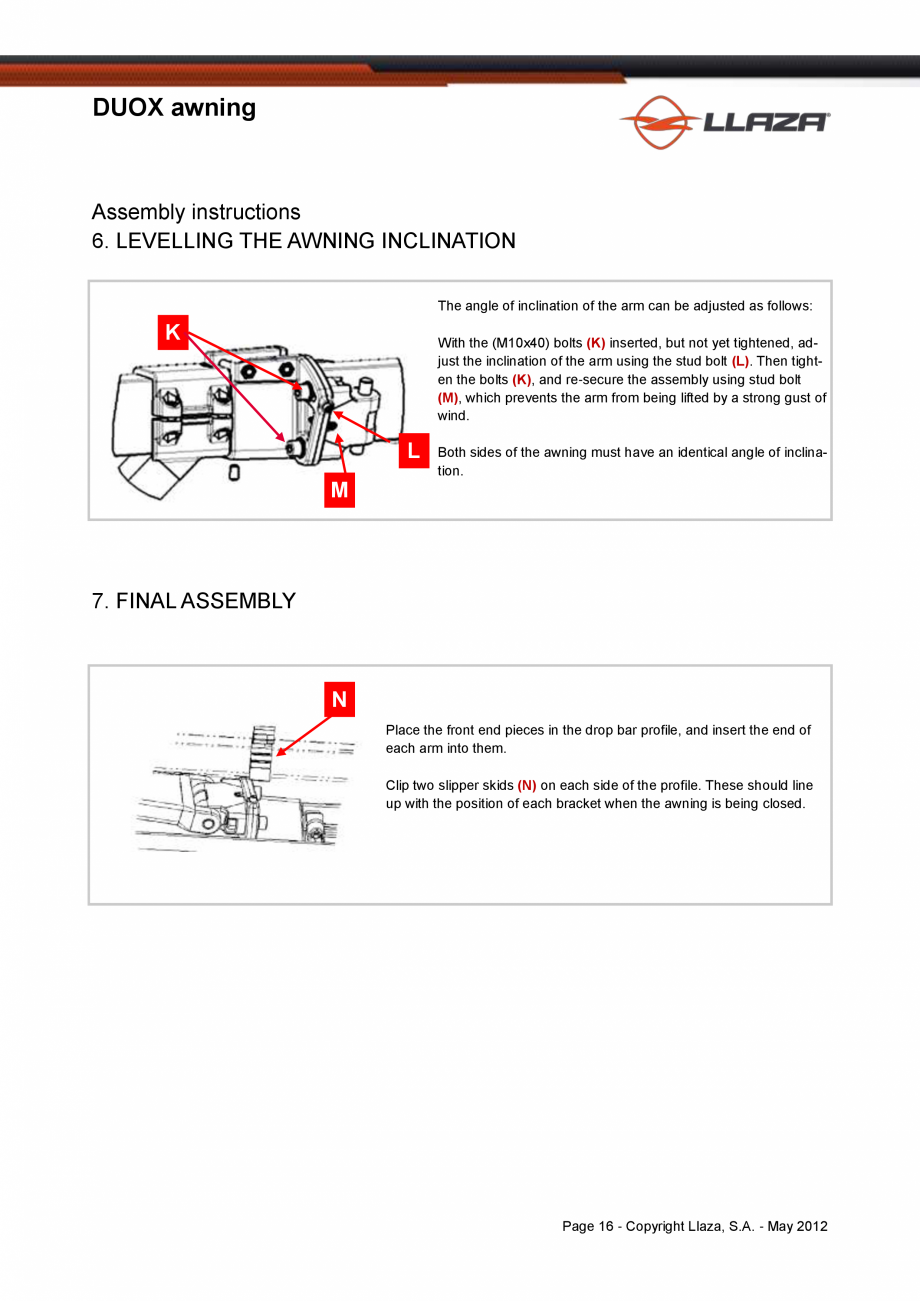

Instructiuni montaj, utilizare

12 p | EN - SP

StorBox 300

Instructiuni montaj, utilizare

12 p | EN - SP

StorBox 250