Perdea de aer arhitecturala pentru usi rotative TEDDINGTON RONDO

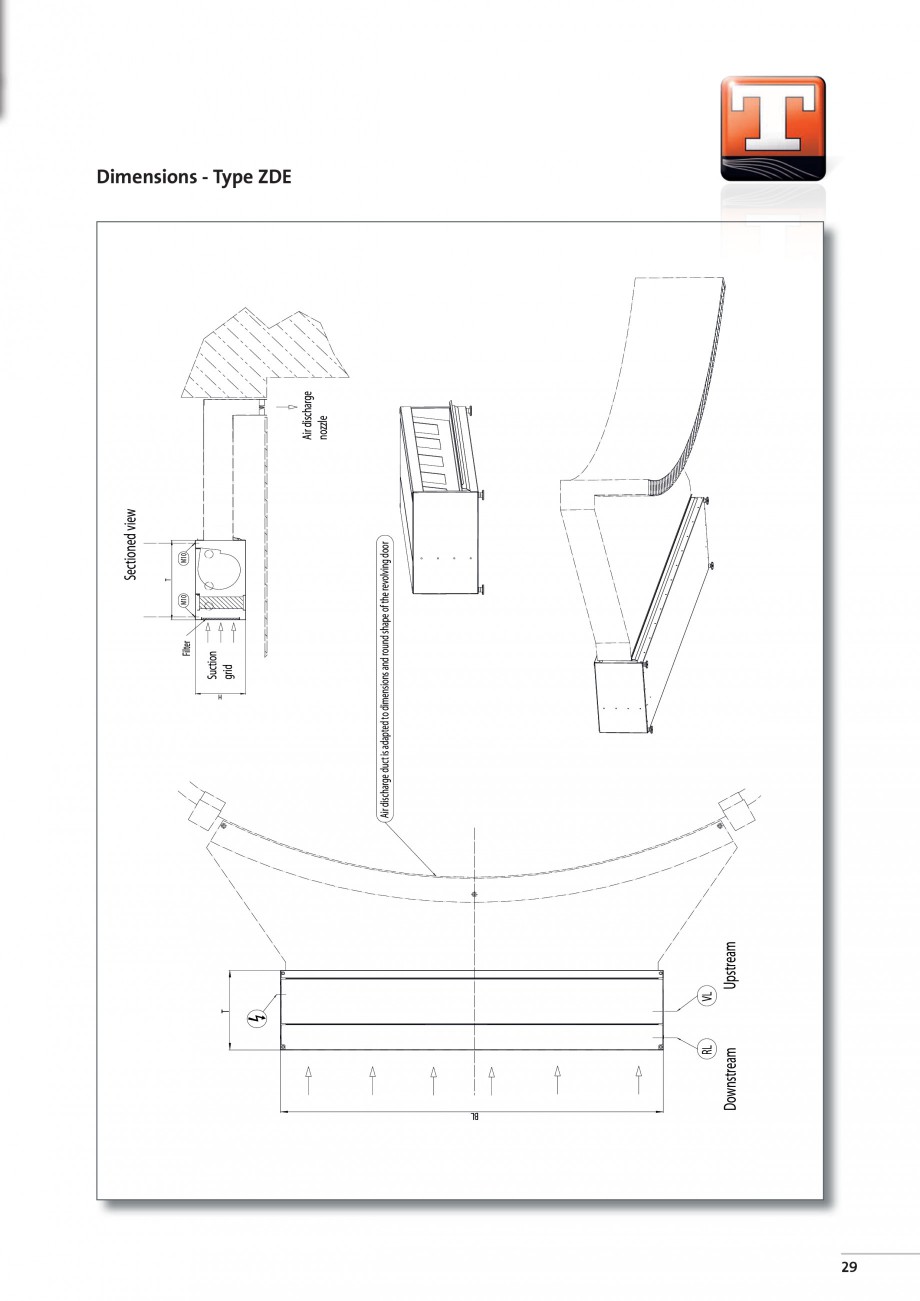

h

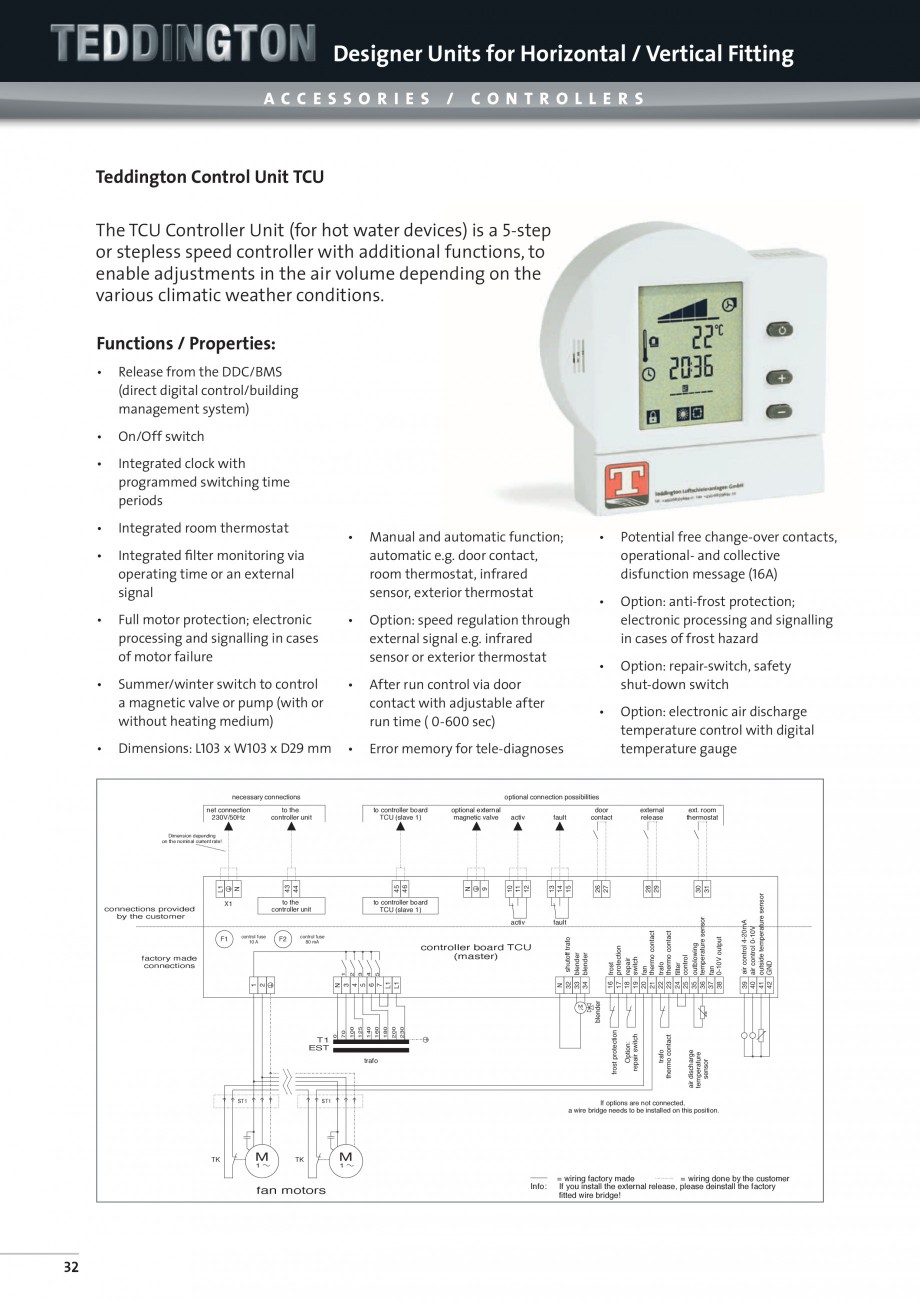

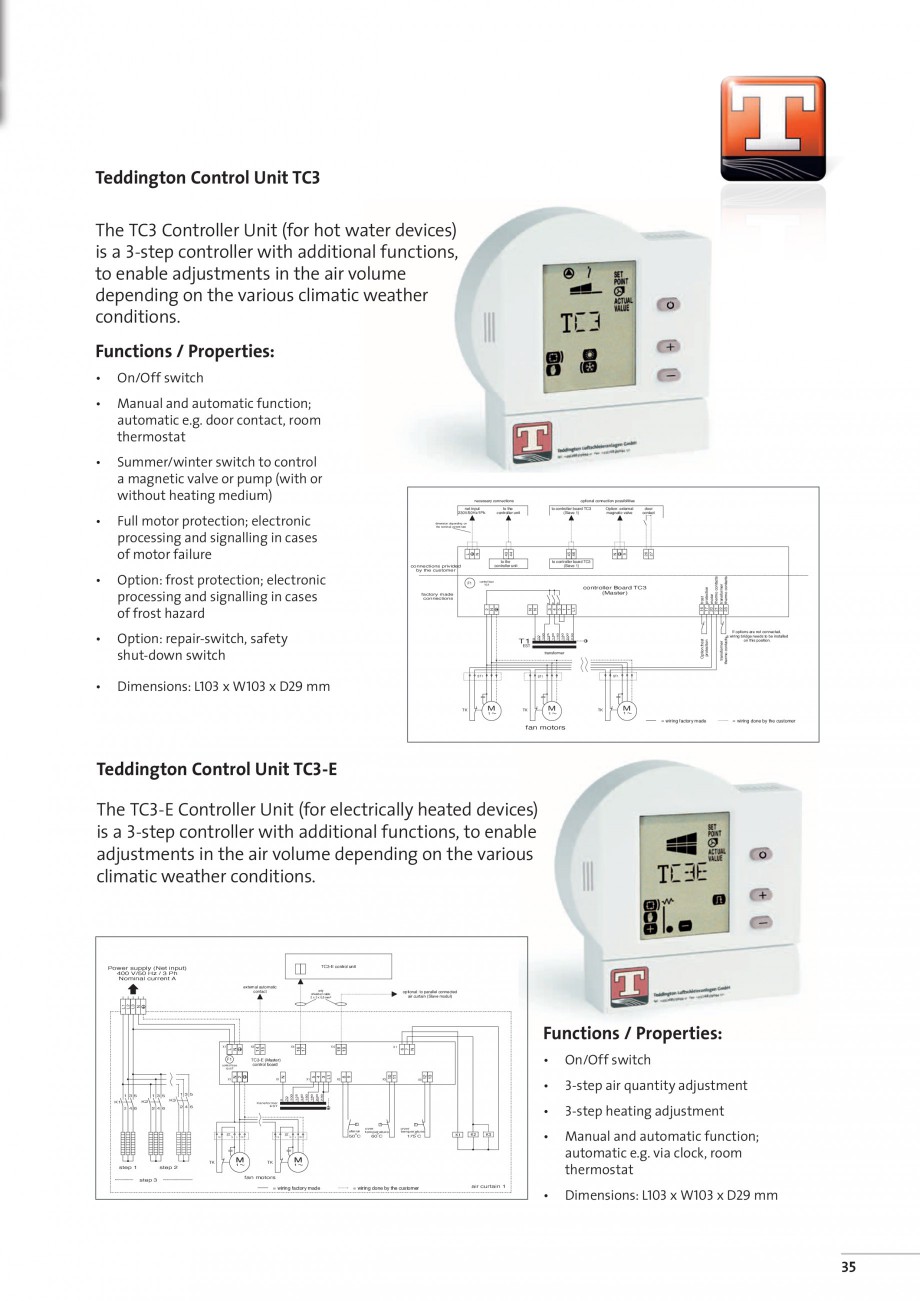

• Integrated clock with

programmed switching time

periods

• Integrated room thermostat

• Potential free change-over contacts,

operational- and collective

disfunction message (16A)

• Integrated filter monitoring via

operating time or an external

signal

•

Manual and automatic function;

automatic e.g. door contact,

room thermostat, infrared

sensor, exterior thermostat

• Full motor protection; electronic

processing and signalling in cases

of motor failure

• Option: speed regulation through

external signal e.g. infrared

sensor or exterior thermostat

• Summer/winter switch to control

a magnetic valve or pump (with or

without heating medium)

• After run control via door

contact with adjustable after

run time ( 0-600 sec)

• Dimensions: L103 x W103 x D29 mm

• Error memory for tele-diagnoses

• Option: repair-switch, safety

shut-down switch

• Option: electronic air discharge

temperature control with digital

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

16 p | EN

CHARISMA

Fisa tehnica

12 p | EN

DELTA