Perdea de aer pentru spatii comerciale si birouri TEDDINGTON C-SERIES

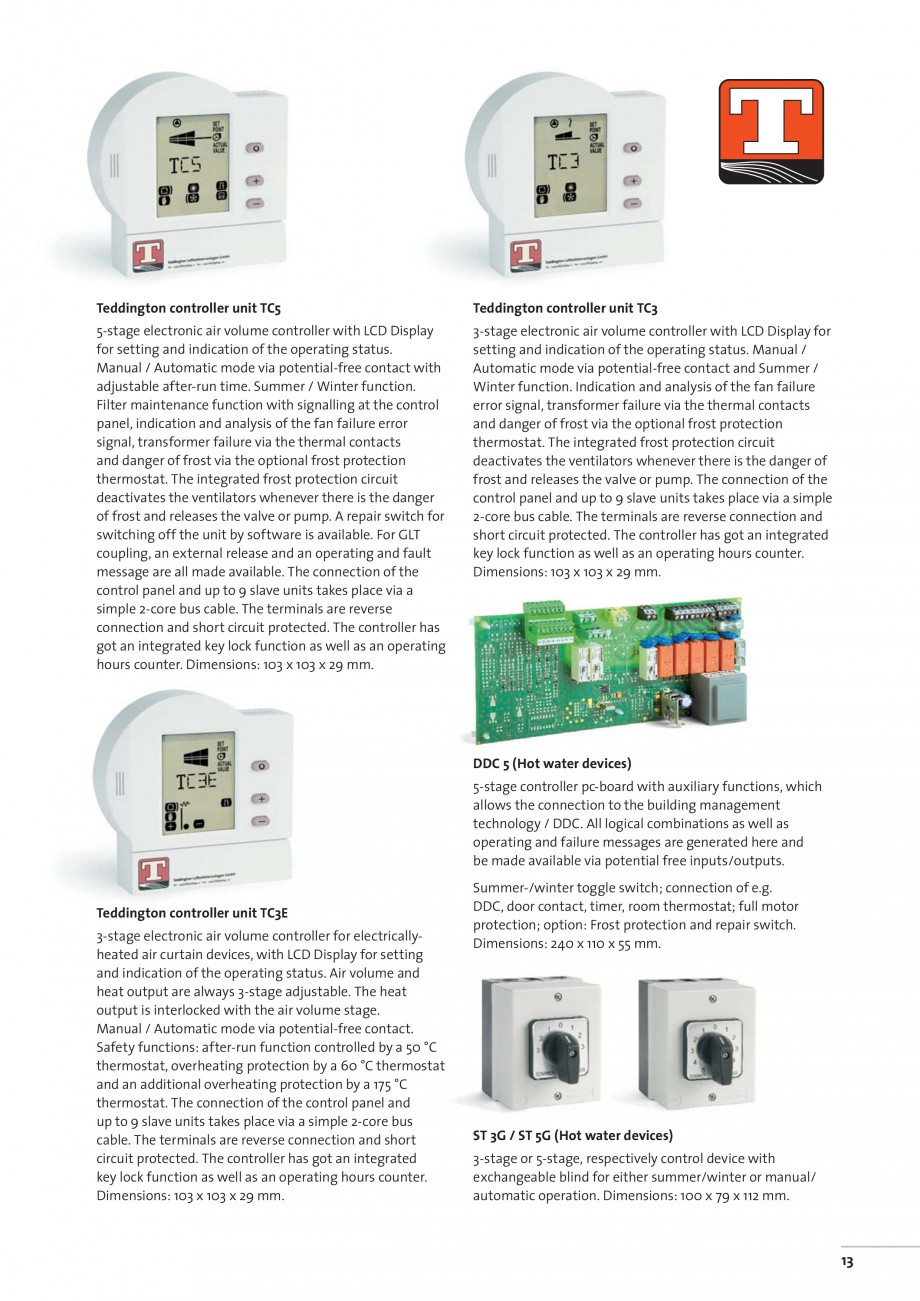

tection circuit

deactivates the ventilators whenever there is the danger of

frost and releases the valve or pump. The connection of the

control panel and up to 9 slave units takes place via a simple

2-core bus cable. The terminals are reverse connection and

short circuit protected. The controller has got an integrated

key lock function as well as an operating hours counter.

Dimensions: 103 x 103 x 29 mm.

DDC 5 (Hot water devices)

5-stage controller pc-board with auxiliary functions, which

allows the connection to the building management

technology / DDC. All logical combinations as well as

operating and failure messages are generated here and

be made available via potential free inputs/outputs.

Teddington controller unit TC3E

3-stage electronic air volume controller for electricallyheated air curtain devices, with LCD Display for setting

and indication of the operating status. Air volume and

heat output are always 3-stage adjustable. The heat

output is interlocked with the air volume

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

16 p | EN

CHARISMA

Fisa tehnica

12 p | EN

DELTA