Placi HPL compact fatade MEG_GEPLAST ABET LAMINATI

Tip documentatie: Specificații tehnice

Salvează pdf

Full screen

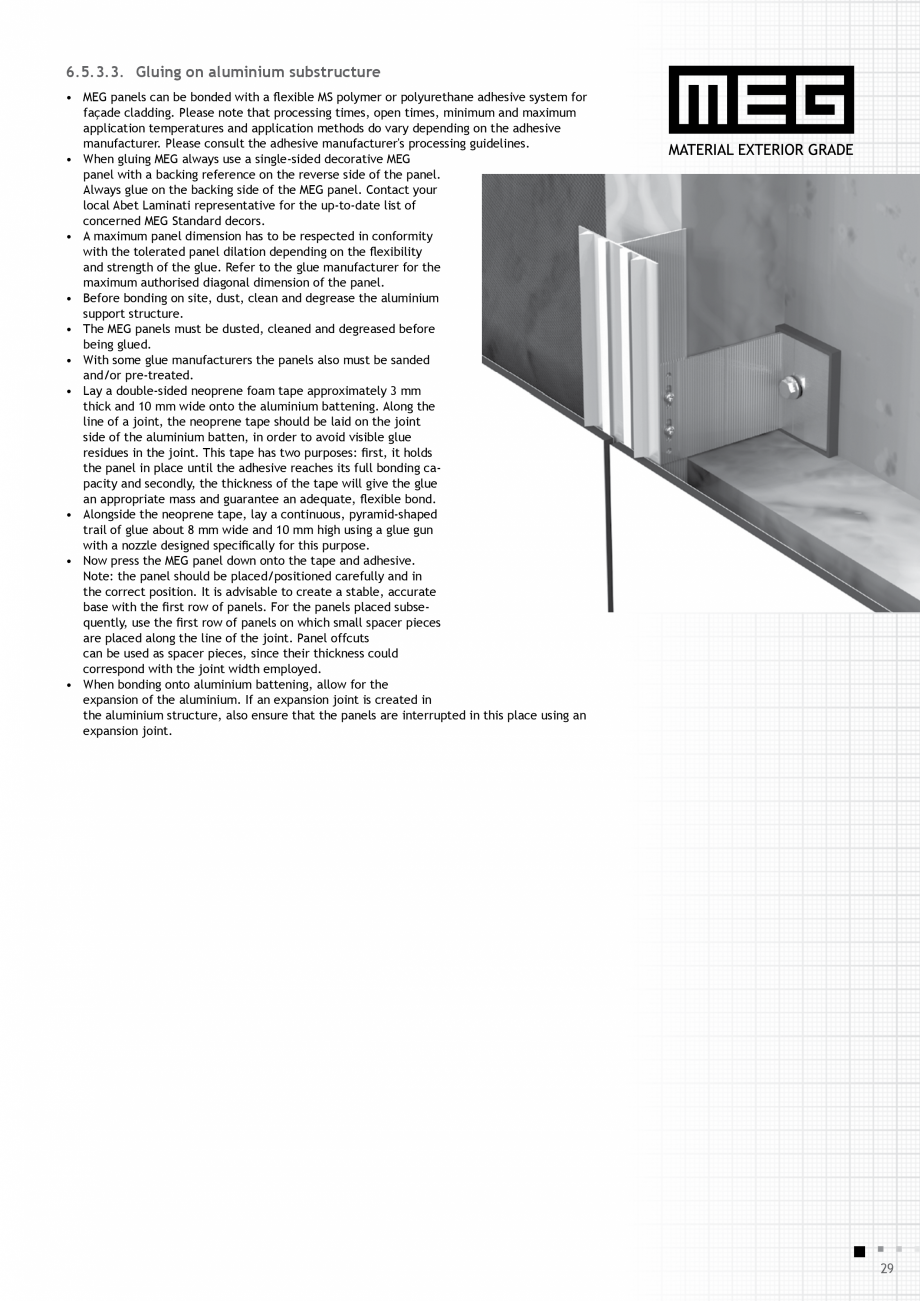

up-to-date list of

concerned MEG Standard decors.

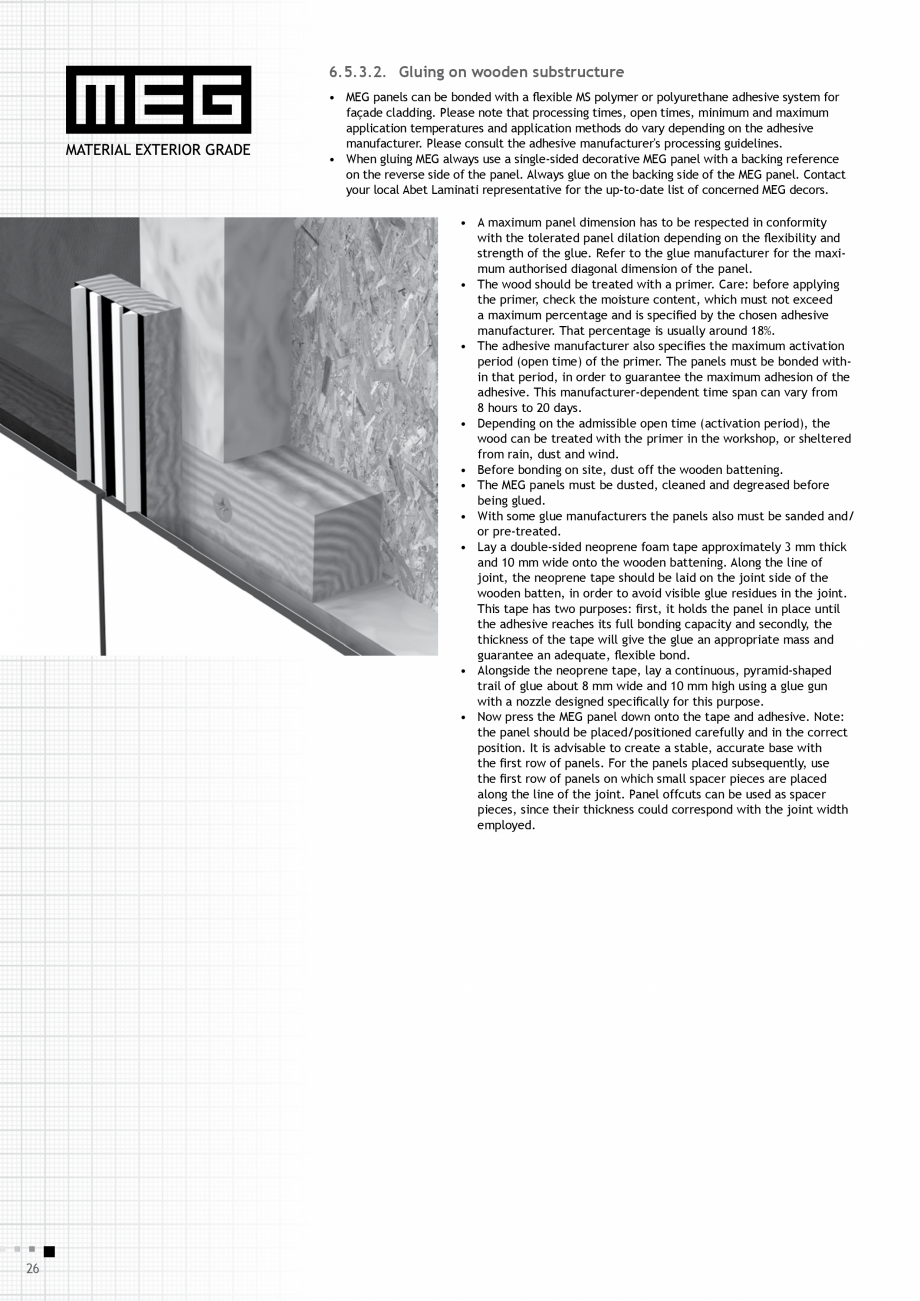

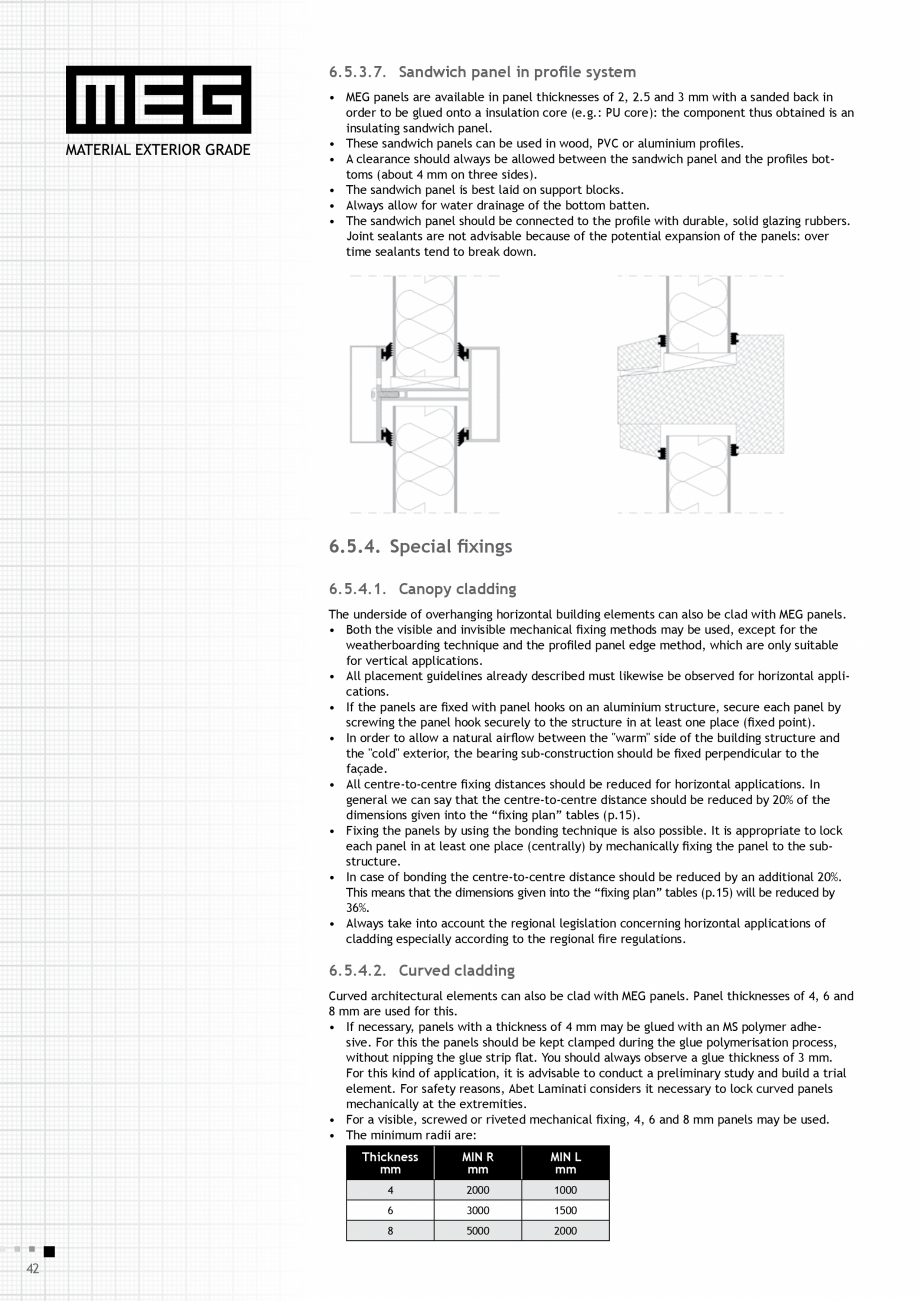

• A maximum panel dimension has to be respected in conformity

with the tolerated panel dilation depending on the flexibility

and strength of the glue. Refer to the glue manufacturer for the

maximum authorised diagonal dimension of the panel.

• Before bonding on site, dust, clean and degrease the aluminium

support structure.

• The MEG panels must be dusted, cleaned and degreased before

being glued.

• With some glue manufacturers the panels also must be sanded

and/or pre-treated.

• Lay a double-sided neoprene foam tape approximately 3 mm

thick and 10 mm wide onto the aluminium battening. Along the

line of a joint, the neoprene tape should be laid on the joint

side of the aluminium batten, in order to avoid visible glue

residues in the joint. This tape has two purposes: first, it holds

the panel in place until the adhesive reaches its full bonding capacity and secondly, the thickness of the tape will give the glue

an appropriate

... ascunde

Alte documentatii ale aceleasi game

Catalog, brosura