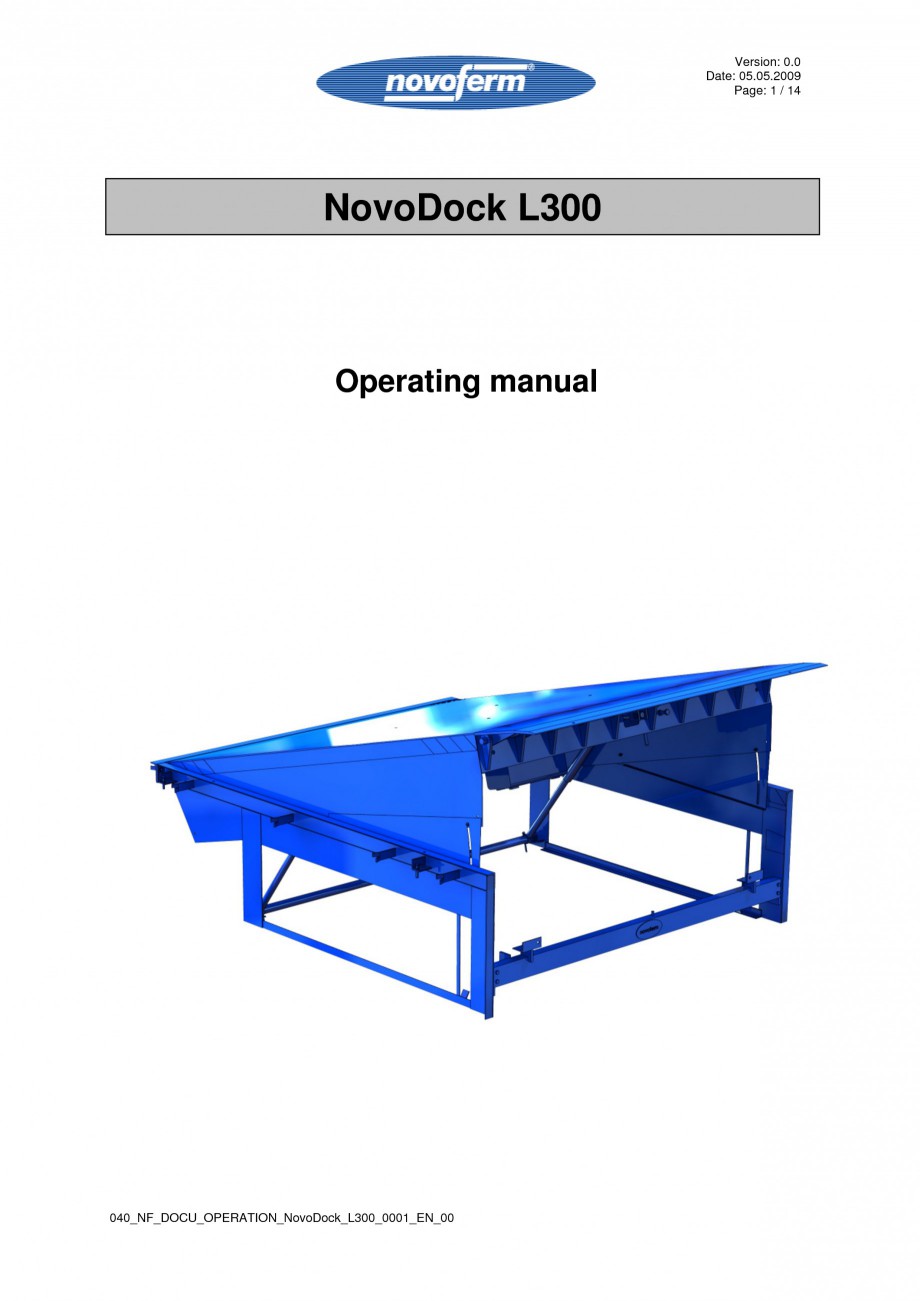

Rampe de incarcare, descarcare - Manual de operare NOVOFERM NovoDock L300

Tip documentatie: Instructiuni montaj, utilizare

Salvează pdf

Full screen

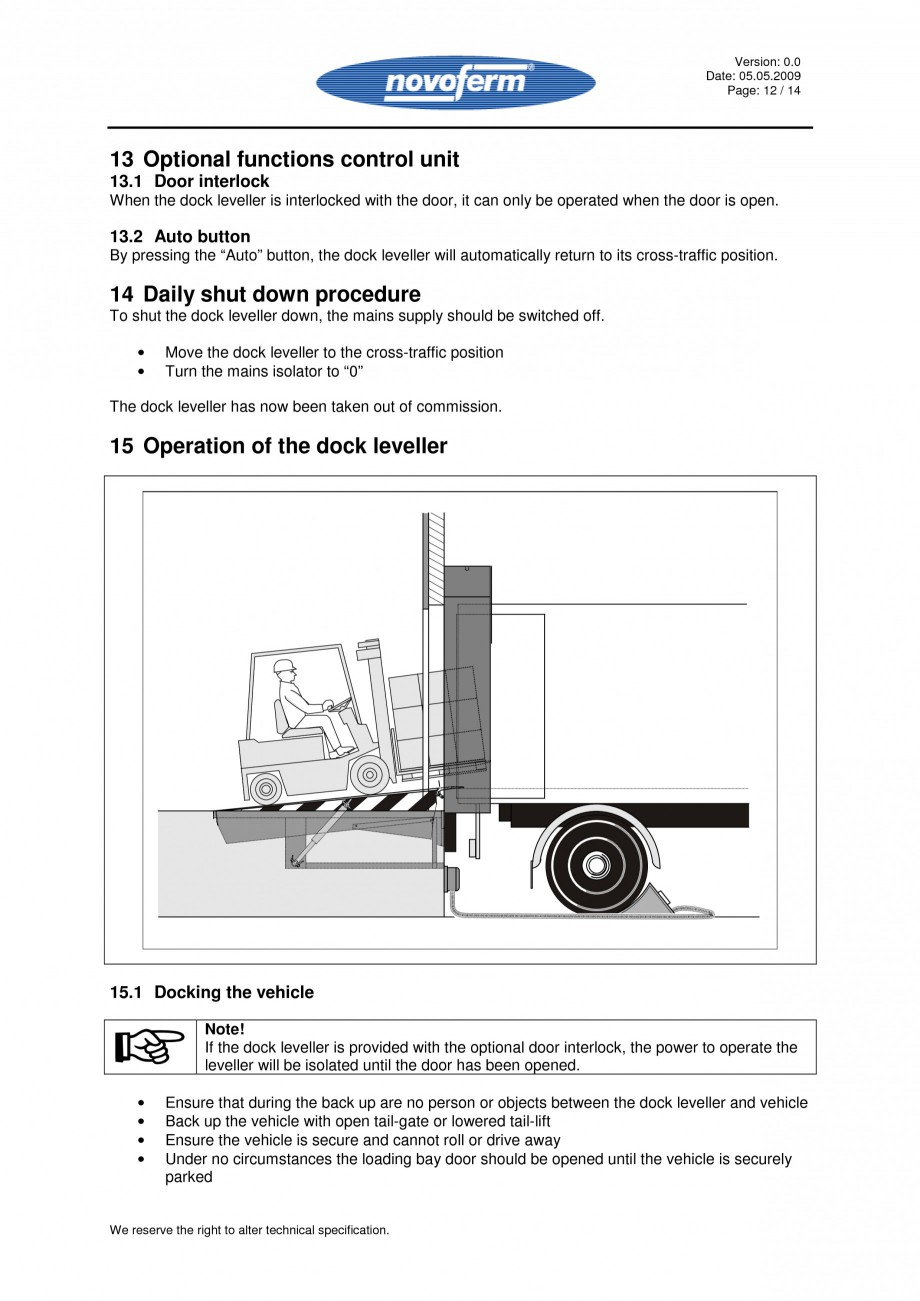

quipment the following safety instructions must be observed. Caution! Make sure that there are no persons in the working area of the dock leveller while the leveller is being positioned or parked. Caution! The dock leveller is to be operated by trained persons (minimum age 18 years) only. During operation, the movement of the dock leveller must be closely watched. Caution! All persons operate a dock leveller must be familiarize with the function. The user has to ensure that all persons concerned have understood the instructions. The operator must have read the operating manual attentively. Caution! In case of emergency, turn the yellow-red mains isolator to “0”. Any movement of the dock leveller will then be interrupted. Any movement of the dock leveller is immediately interrupted if: • the mains isolator is switched off or • the mains supply is interrupted After any interruption to the dock leveller power supply, the push button “Lift” must be pressed after restoration of

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

20 p | GE

NovoDock L300 NovoDock H1300 NovoDock H1500 NovoDock L100 NovoDock L150 NovoDock L350i NovoDock P1300i NovoDock P1500i

Instructiuni montaj, utilizare

18 p | EN - GE

NovoDock L300