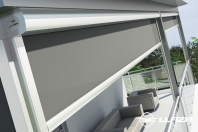

Rulou din material textil perforat LLAZA Bip 300

Alte documentatii ale aceleasi game Vezi toate

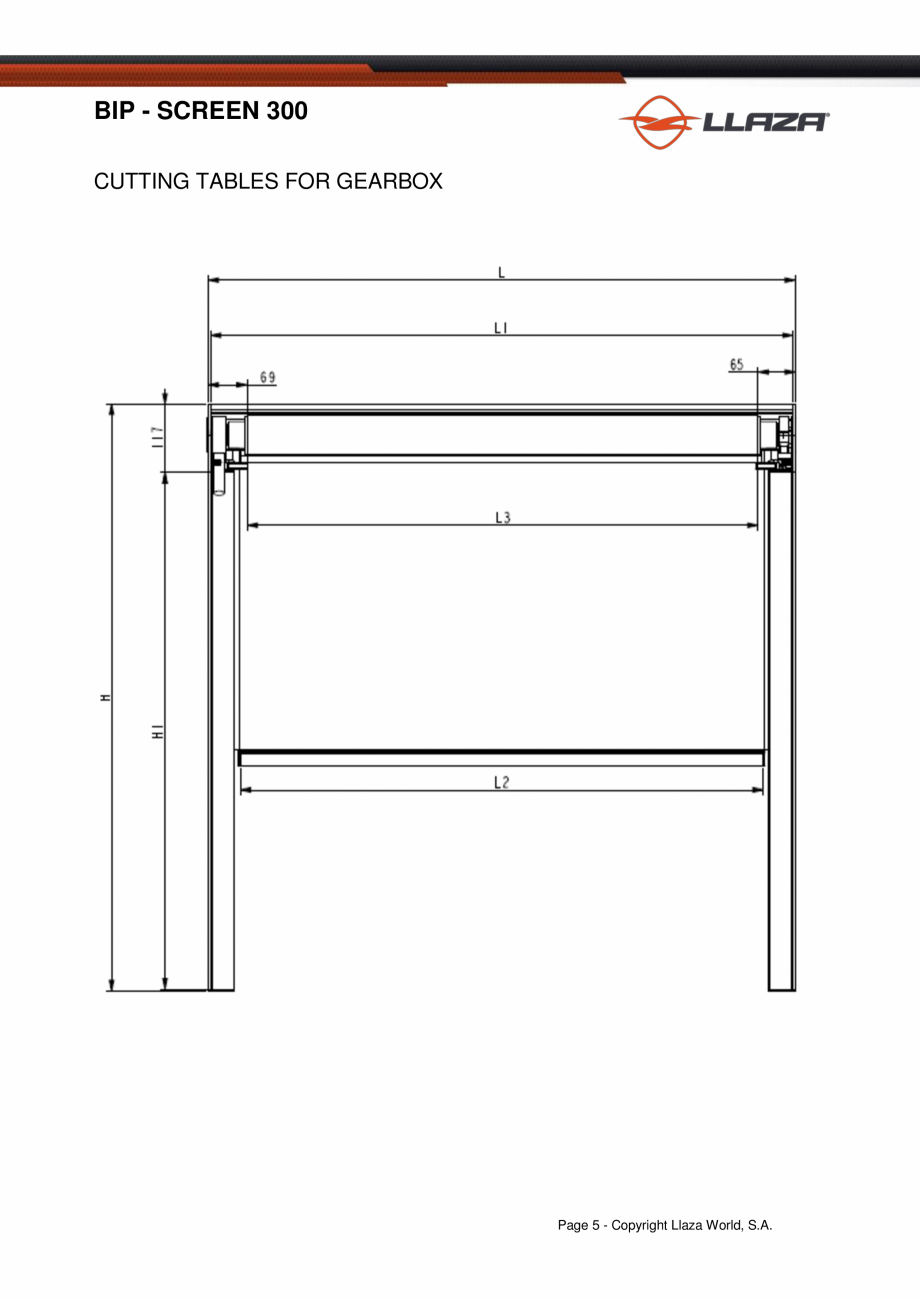

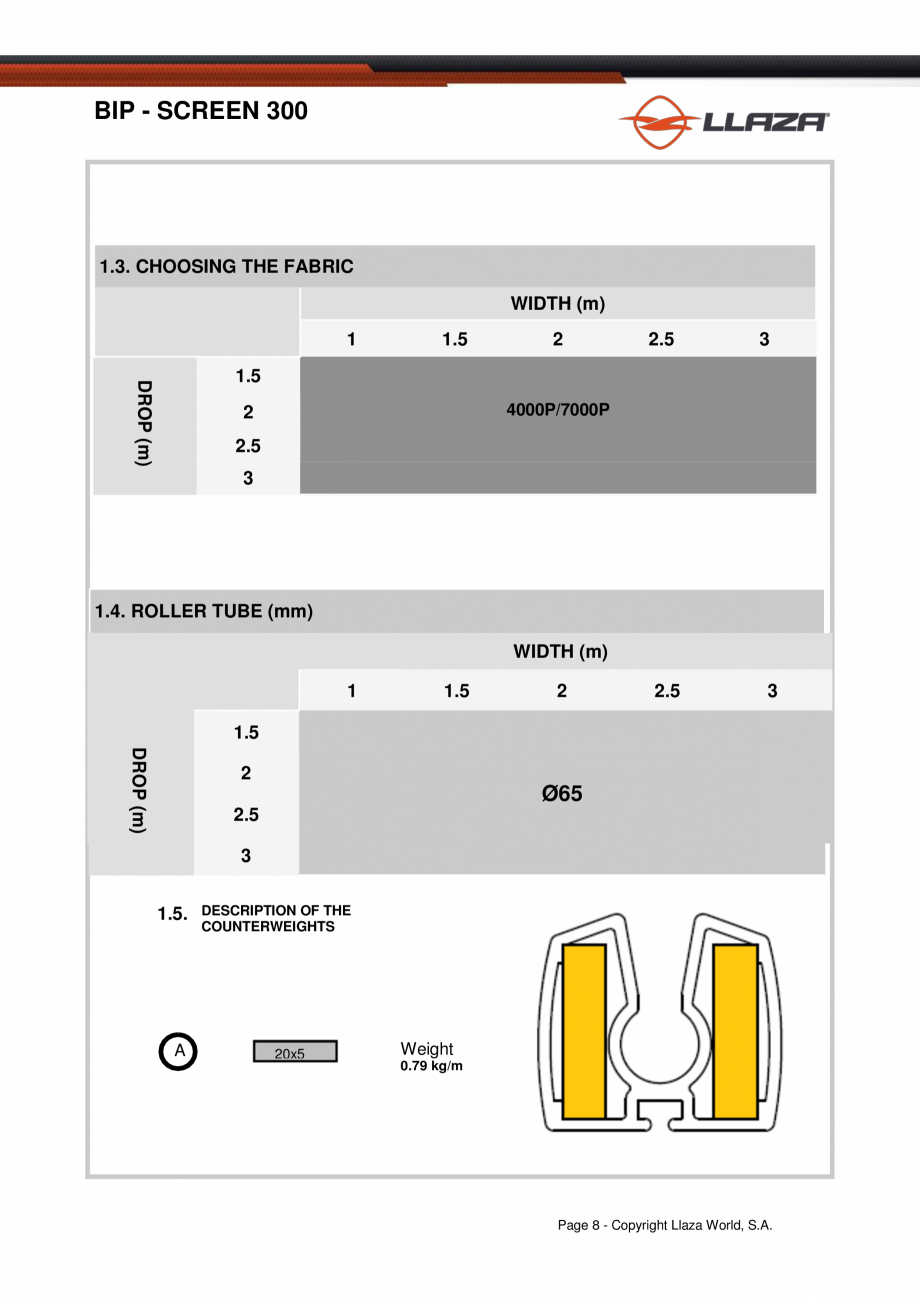

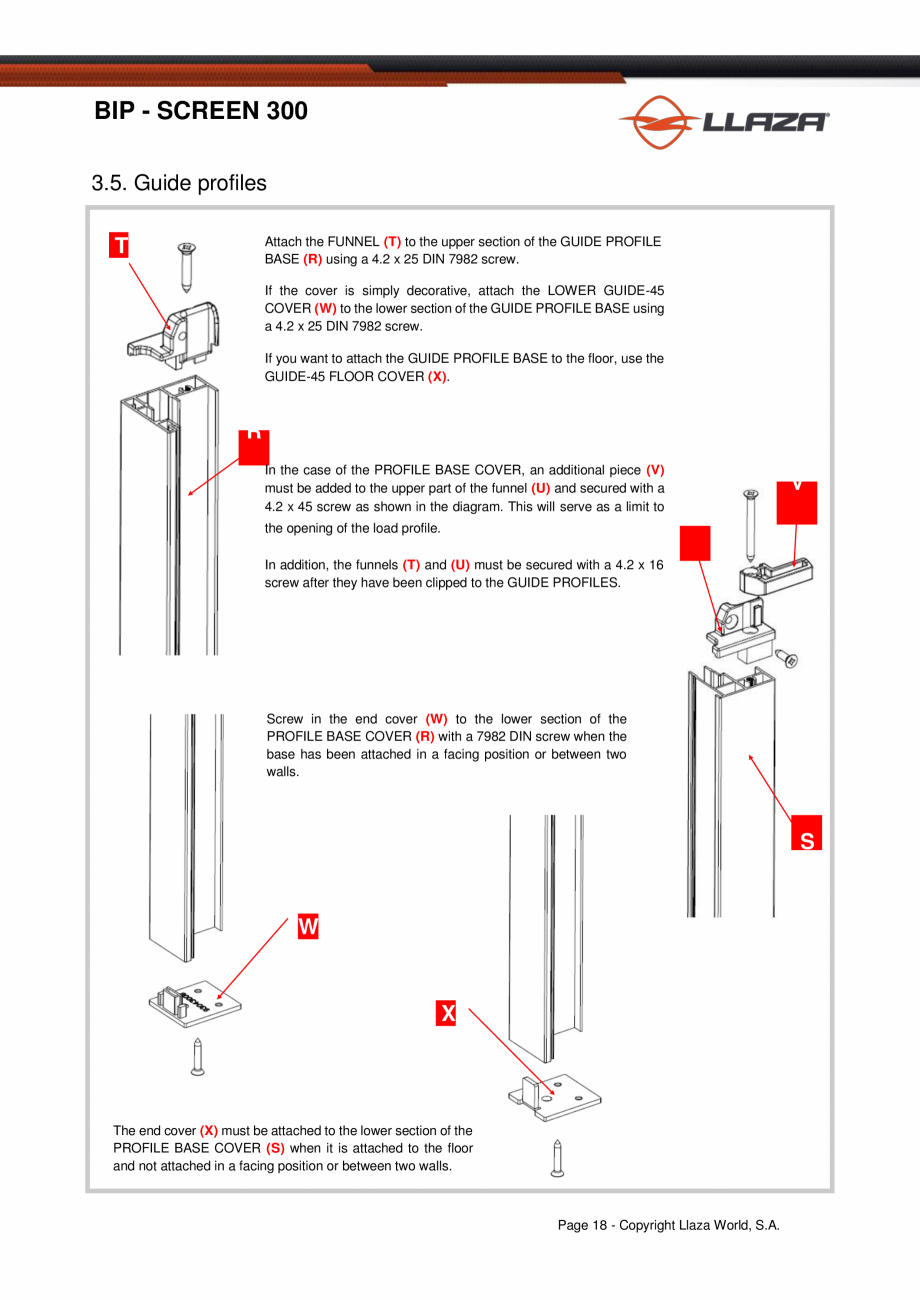

Fisa tehnica

28 p | EN

Bip 500

Catalog, brosura

706 p | EN

Bip 300 Bip 500 Maxi Screen Aluminiu Lemn