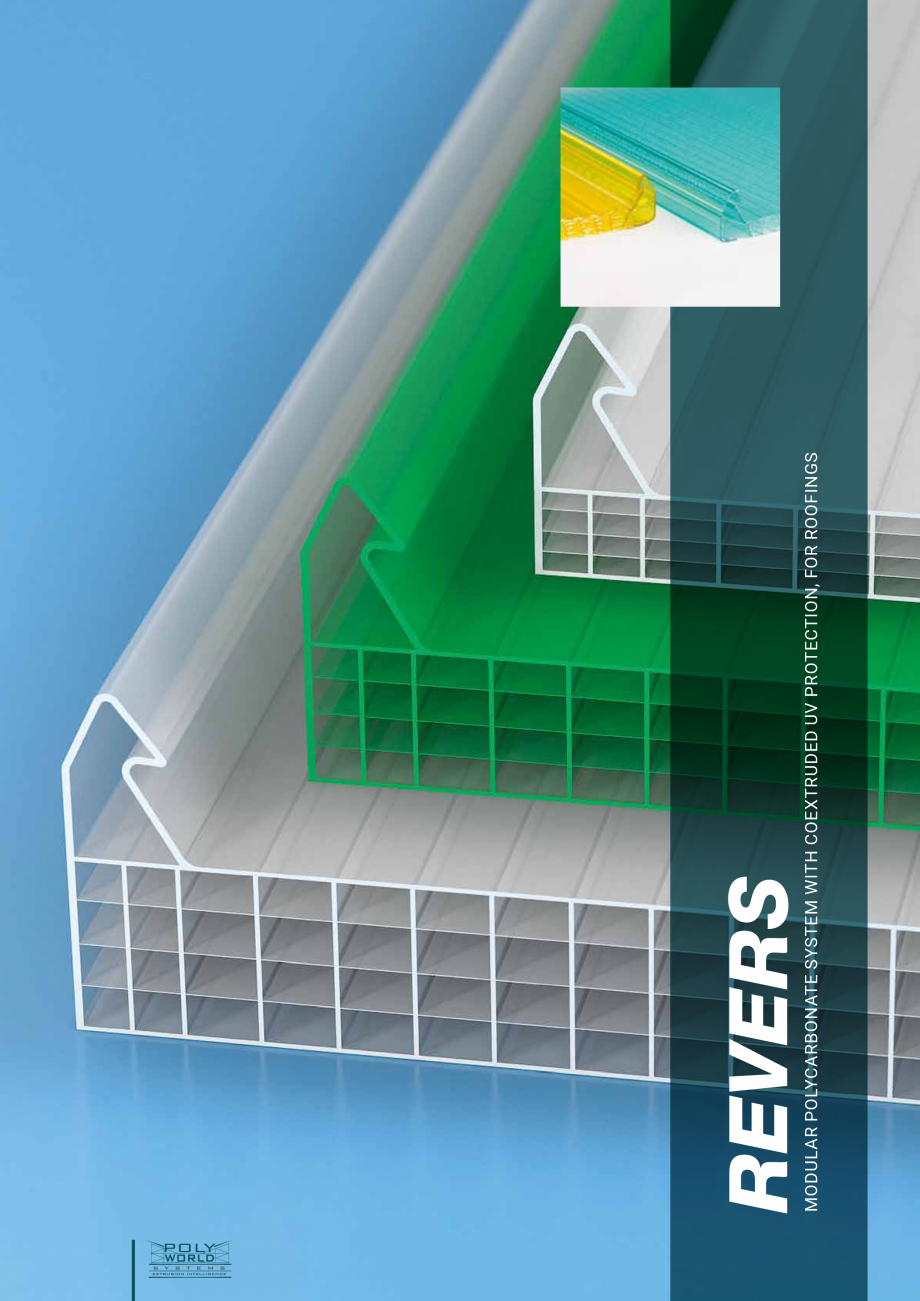

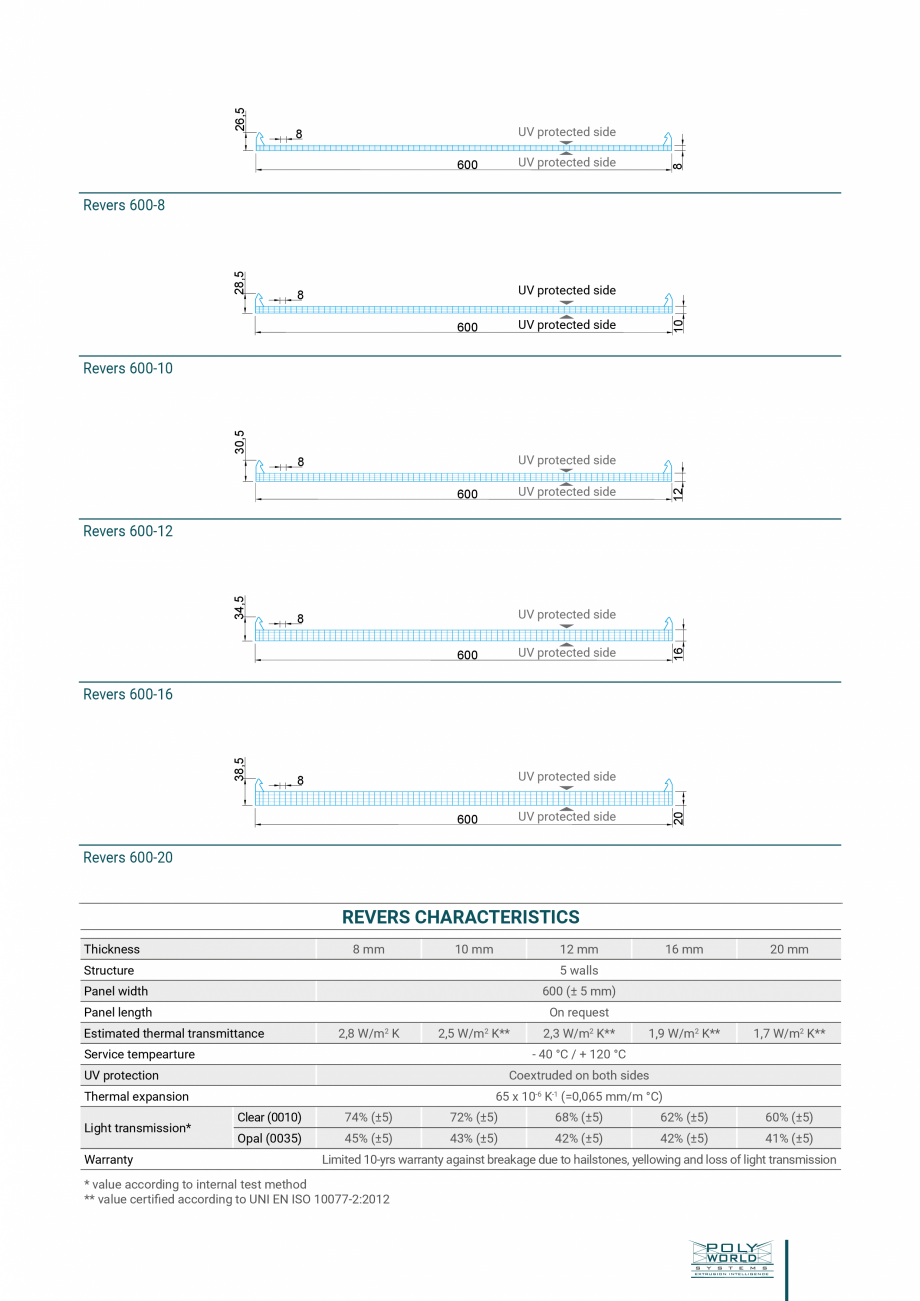

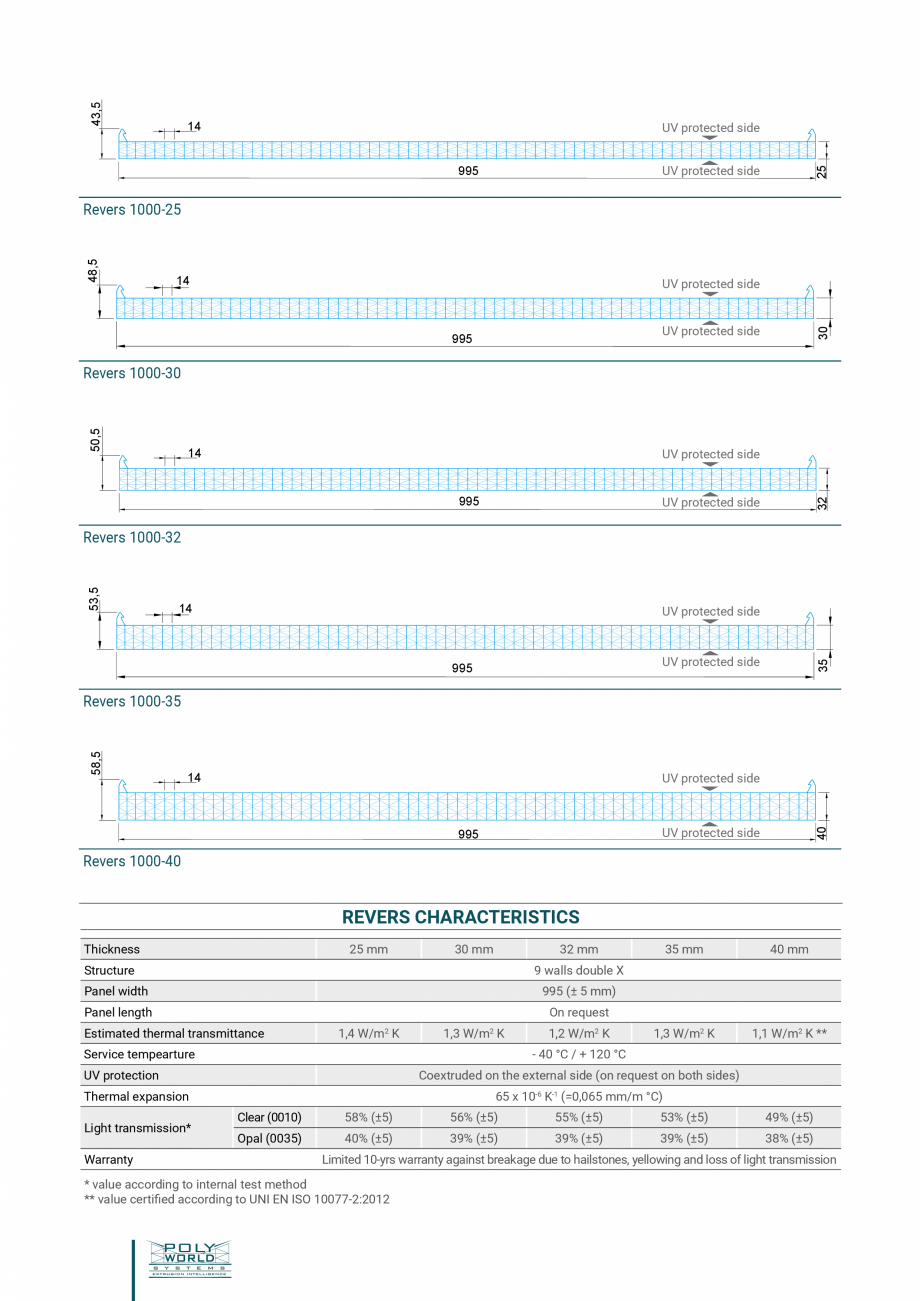

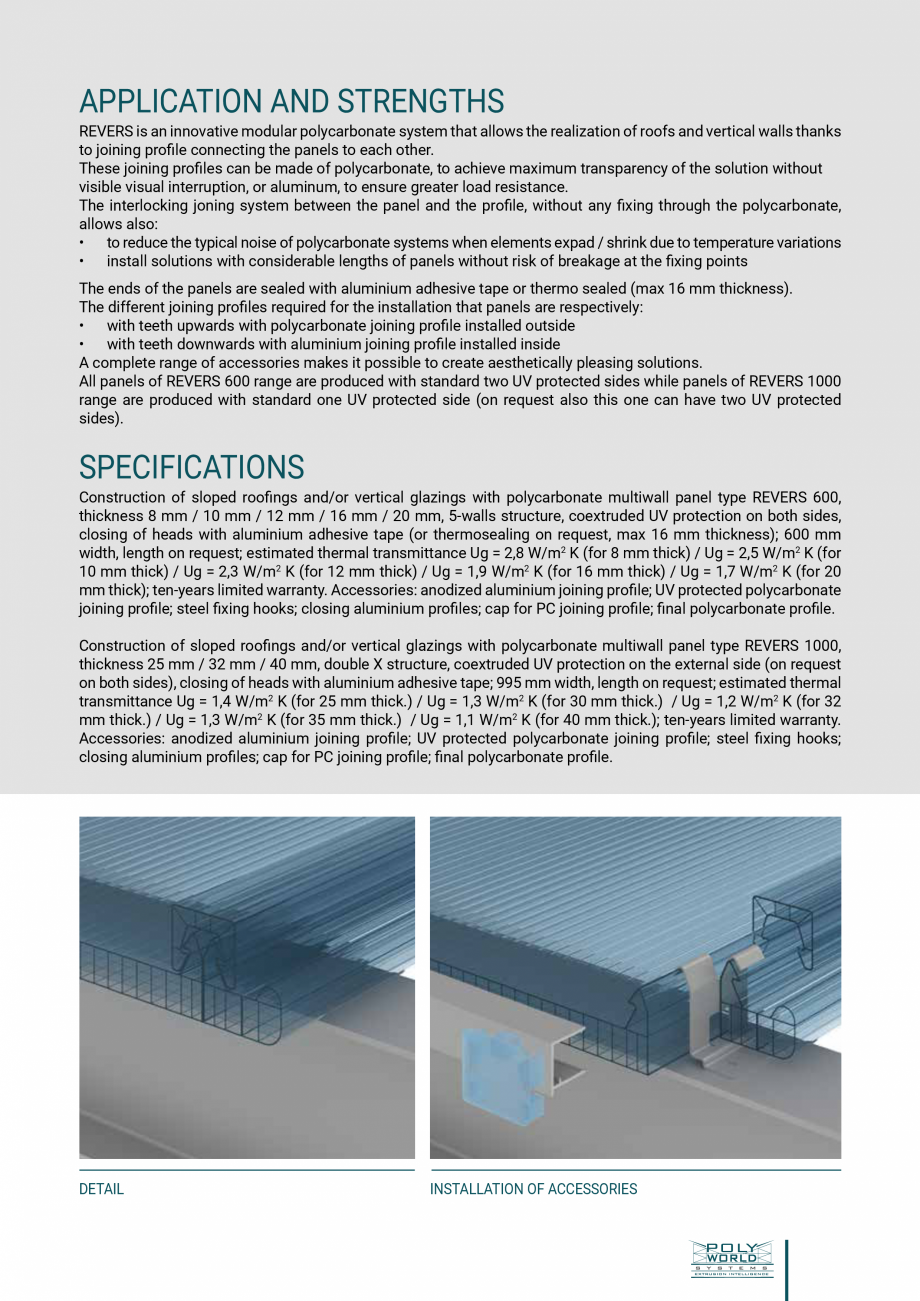

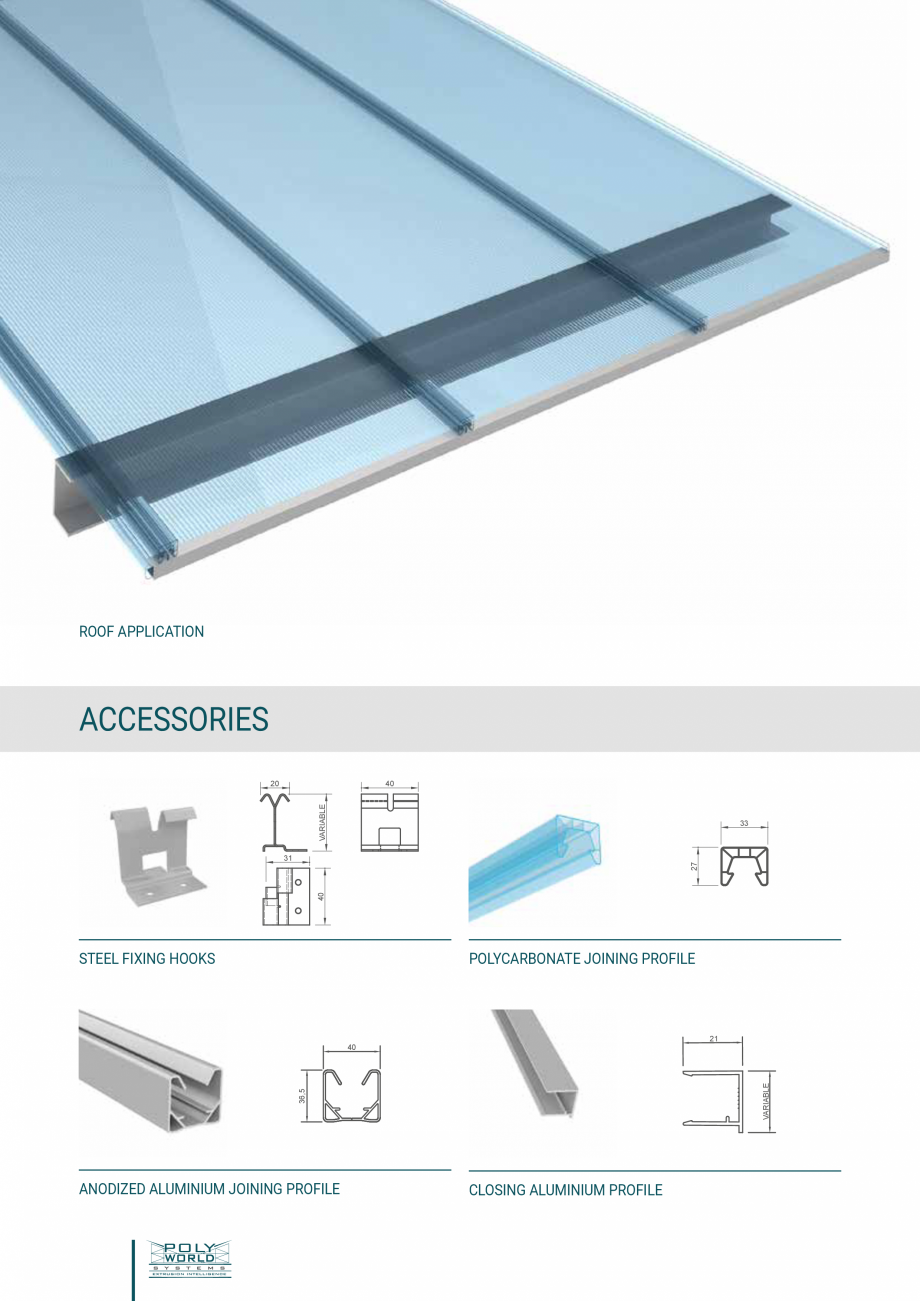

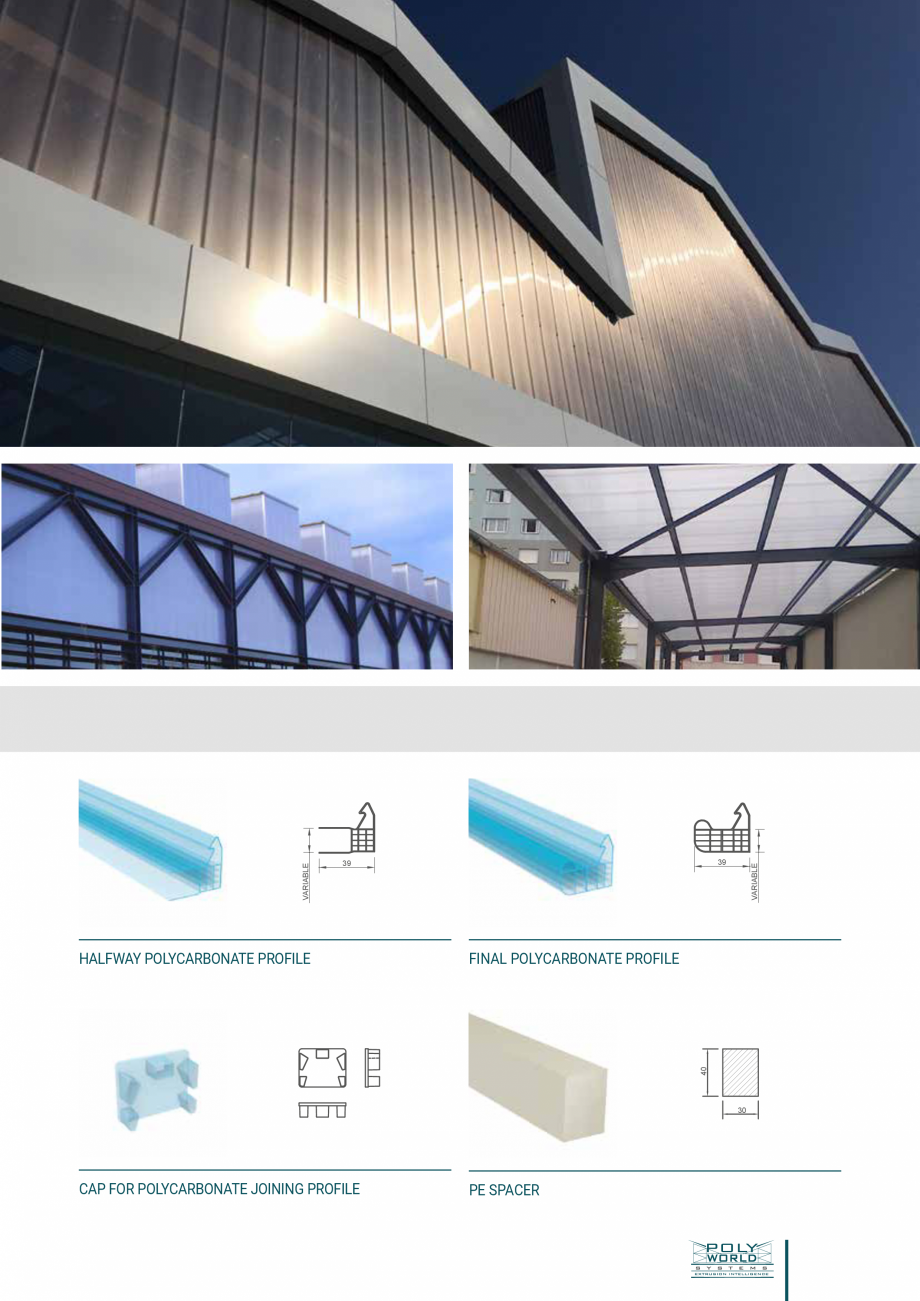

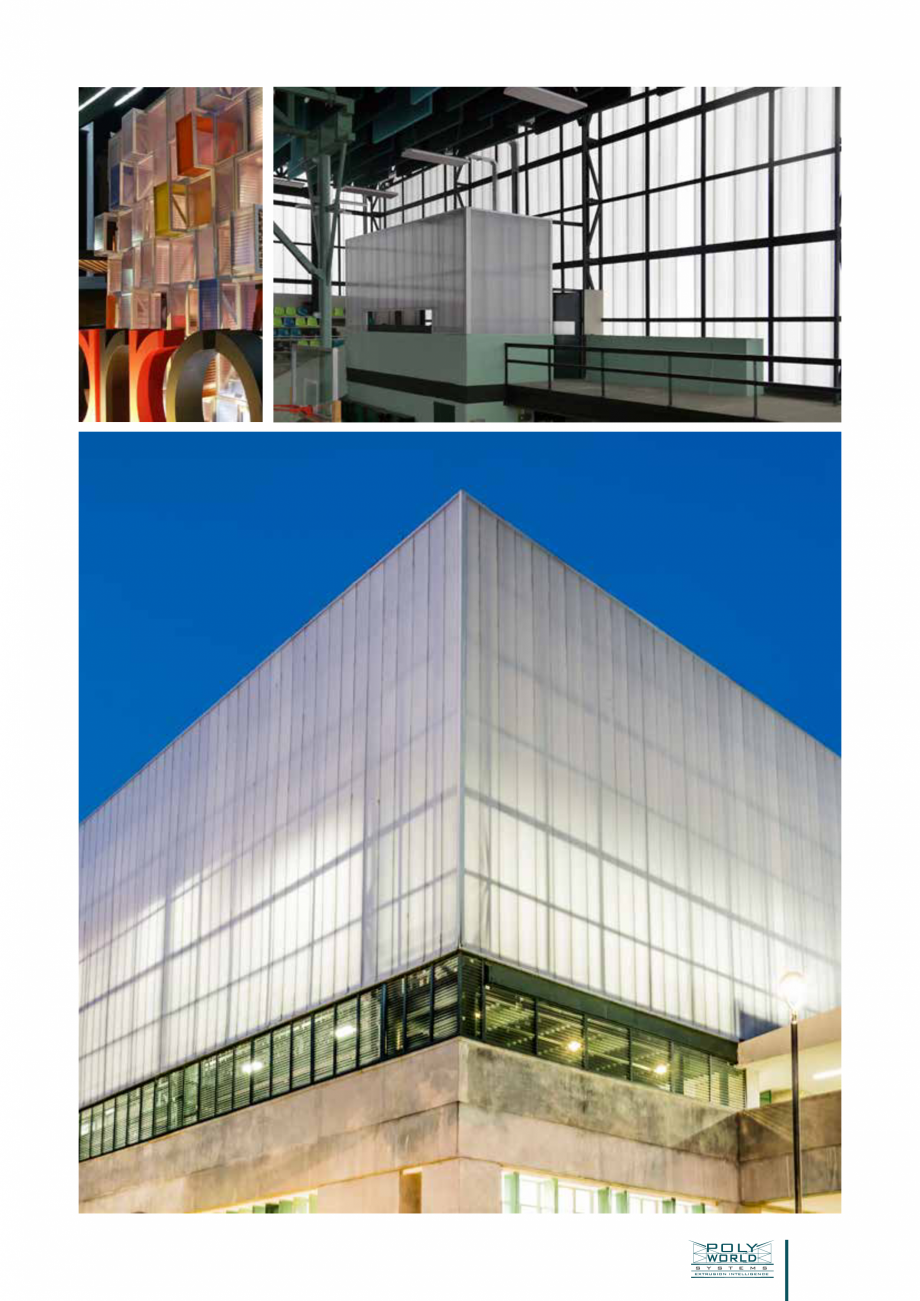

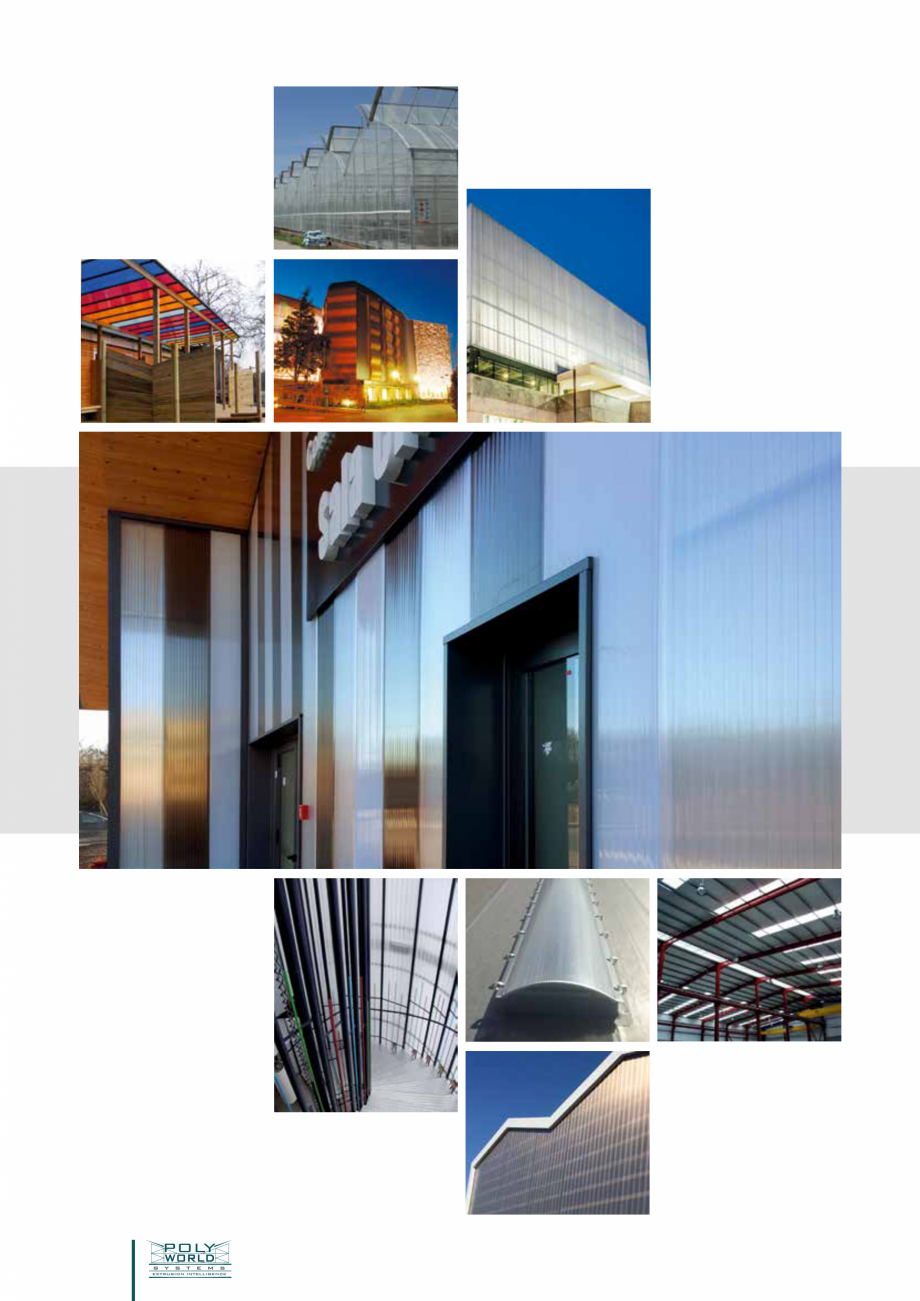

Sistem policarbonat pentru pereti cortina si acoperisuri GEPLAST REVERS

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

6 p | EN

GRECA

Fisa tehnica

7 p | EN

NUT-FEDER WALL